We've been seing a 0.5Hz resonance (plus harmonics) on BSC-ITMX (this Jeff's summary here). We investigated more on that today.

This half hertz:

- appears on ALL the sensors of the ISI on X,Y and RZ

- appears on ALL the sensors of the ISI on H1,H2 and H3 (which makes sense according to the previous statement)

- doesn't appear on HEPI

- appears on M0 Longitudinal, but with a much smaller amplitude

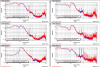

We've tried different configurations. We first noticed this issue with HEPI position controlled and ISI fully controlled (Ctrl lvl1 on ST1+ST2, T100mHz blend filters on ST1-X and ST1-Y, 750mHz blend elsewhere).

- It disappears when the ISI is under damping only.

- It reappears when only ST1 is controlled.

Weird thing: it doesn't appear when only ST1-X controller is ON, but it DOES appear when only ST1-Y controller is ON.

Also, to be sure that the issue wasn't coming from the actuators, I drove a white noise on ST1-X and ST1-Y (damping only). It didn't appear.

At this point, I would guess we're having a CPS/ground issue again, with no conviction. We'll try to monk with the electronics Monday.

To finish, I just want to remind that we have a temporary solution, which is putting a narrow notch at this frequency into ST2-CPS blend filters. With this temporary fix, we are pretty happy about the ISI performance.