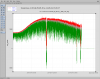

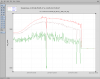

I believe the ITMX optical lever signals are calibrated in urad. If that's the case, the ITMX PIT motion right now is 0.3 urad RMS (this is with the ISI in the configuration Rich left it in). All the RMS comes from 0.1 - 0.7 Hz and I see 1 urad / sqrt(Hz) @ 0.5 Hz. This is significantly worse than ETMY/ITMY motion during the one arm test (0.2 urad/ sqrt(Hz) and 0.3 urad / sqrt(Hz) @ 0.5 Hz T1200450), and normal operations at LLO (0.4 urad RMS, and 0.05 urad/ sqrt(Hz) at 0.5 Hz - LLO log 8637). Need to double check that I am comparing apples to apples.

Don't you mean an RMS of 0.3 rad for pitch? At least, if the vertical axis is in microradians.

Yes, bad typo, I fixed the entry.