Over the last few days I've been taking some passive noise spectra of the ISI-CPS on HAM6 to try and determine what the best grounding strategy is (Jeff made a nice cartoon of the options in T1300871).

Along the way I found out a few things

1) The HAM 6 CPSs had two problems that canceled each other out

There as a master in each crate (the box near the chamber that hold the CPS controllers)

and the cable which brings the sync signal from the power board was either bad or plugged in backwards (it isn't keyed)

I tunred one of the masters into a slave and replaced the cable

2) All of the racks that I have tested have there chasis grounded, so placing them on a cable tray creates a ground and possible ground loop.

3) Currently it is pretty likely that ALL of the CPS that are installed have grounds in the electroncs room rack AND at the chamber (Ground Loop Gaore)

4) The resistance to ground from the power cable ground to the chamber is 0.6ohms

5) the sync cable carries a ground from one rack to the next

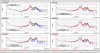

After fixing the problems I took spectra under three conditions

Multiple grounds (electroncs room and chamber) these were bad

Single ground in the electronics room, red and green lines in the attached png (clean room on/off are the differences)

Single ground at the chamber, blue lines in the attached png

Given that set of data i think that we should plan on converting to a single ground at the chamber.

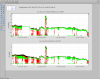

The attached pdf shows one spectra converted to m/rthz and the expected noise (we have measured something close to the expected noise on the bench for every unit in use)

I don't really know what to say about this except yuck