Summary: Some optic(s) might have moved after the TMS was moved out of the lab.

After the beam centering on QPDs is engaged, the QPDs were nicely centered but the beam spot on the 2ndary was about 3mm off centered to the left, the beam is clipped on the F2 already, and only half or less of the beam makes it to the ETM.

If the TMS ISC table is as was adjusted in the lab, the beam spot should be slightly to the right and a few mm down (https://alog.ligo-wa.caltech.edu/aLOG/index.php?callRep=7285), so there's a huge difference between what we expect and what we are observing now. There are two possibilities:

- We're fooling ourselves, e.g. QPD is looking at a ghost beam, imbalanced analog gain between quadrants etc.

- One or more optics moved on the TMS ISC table, e.g. something was loose, somebody bumped on the mirror holder etc.

In the latter case we somehow need to realign the green and IR beam to the telescope and recenter the green and red QPDs, all in situ. I'm working on a procedure to do this.

Checking that we're not fooling ourselves.

Sensing electronics offset? -> Exonerated (changing whitening gain didn't change the beam position though it increased the QPD signal)

Beam clipping downstream of Mad City Labs PZTs? -> Exonerated. No clipping in chamber, and the beam looks OK in chamber.

Different gains for quadrants? -> Asked Stefan to check by bringing the beam in one quadrant, one by one.

Ghost beam?

Wrong polarization (which might produce strong ghost beams)?

Identifying what moved and why.

We don't have any good idea to pinpoint what moved except that it should be downstream of the first steering mirror, and either upstream of the secondary or in the QPD path. Optics mounted at the edge of the table are more likely to be bumped.

Loose mount? -> Exonerated. Wiggled all relevant optics (except the fixed top periscope mirror on the TMS ISC table, which I overlooked and should be checked later) by touching the barrel of the mirrors using fingers, but after each attempt the beam position didn't change.

Bumping? -> Not fully rejected. I didn't apply strong pressure nor any strong impact to optics, so bumping-strongly theory is still alive.

Drift? -> Not that likely. We have observed during HIFO-Y a huge alignment drift correlated with ambient temperature (triggered by clean room on/off) and nobody knows why this happens. But at that time we were probably talking about the radius of ITM over 4km = 17cm/4km ~ 40urad drift, while this time it is 3mm on the TMS ISC table, so it's on the order of a few mrad. This is a much larger effect than the drift in the past.

We're soliciting ideas for failure modes NOT listed above as well as the checks that could/should be done before going ahead to change the TMS ISC table alignment.

Here are pictures Stefan and Keita took inside the chamber.

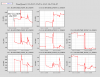

I very crudely tested the gain of each QPD segment. I just used the offset in pitch/yaw of PZT2 to move the beam onto each segment. The gain of each segment of QPDA was exactly the same. The gain of each segement of QPDB was within 4% of each other. A dither/demod might be a better test, but at first glance the gain segements look OK to me.