PRM lower masses transfer functions from July 15th have been exported and are plotted in the attached documents below

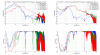

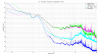

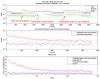

(1) H1 PRM M2-M2 (July 2013) TF in 3 DOF (L P Y) plotted against hsts model (in blue) L1 PRM (July 2013 in orange ) and H1 PR2 (July 2013 in pink)

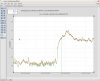

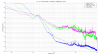

(2) H1 PRM M3-M3 (July 2013) TF in 3 DOF (L P Y) plotted against hsts model (in blue) L1 PRM (July 2013 in orange) and H1 PR2 (July 2013 in pink)

Both set of measurements are showing good agreement with the model, llo prm and lho pr2

Data, scripts and pdf files have been commited to the svn as of this entry

Note :

Since PRM M2 triple acquisition driver chassis hasn't been modified yet, the calibration factor in "calib_hsts.m" (living in sus/trunk/HSTS/Common/MatlabTools/) has been set to 0.32 mA/V, as described in the hsts electronics drawing summary. Value will need to be changed to 3 mA/V accordingly with driver's modif.