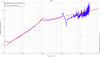

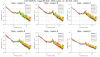

Results of ETMX main and reaction chain top mass transfer functions for Phase 2c, after final alignement, are attached below. Most of the measurements are showing good agreement with the model, except for pitch, as on last thursday. The first two modes of the main chain @~0.55Hz and ~1.30Hz appears to be shifted down in frequency (page 5 of first pdf). The second pitch mode of the reaction chain @ ~ 1.33Hz is shifted up, and we can see vertical to pitch as well as transverse to pitch cross couplings from the extra 2Hz and 2.22Hz resonnances (page 5 of the second pdf). After plotting ETMX pitch transfer function against other fiber quads (3rd pdf), it seems like a common feature between quads. The results will be discussed during the sus meeting, but are approved for now since livingston ITMY looks identical.

Plots attached are described below :

1- H1 M0-M0 ETMX phase 2c main chain top mass transfer functions (in red) against "fiber" model (in blue), for the 6 degrees of freedom

2- H1 R0-R0 ETMX phase 2c reaction chain top mass transfer function (in red) against "erm (end reaction mass)" model (in blue), for the 6 degrees of freedom

3-a) Pitch to pitch main chain comparison between model and other fiber quads : L1 ITMX (June 2013, orange), L1 ITMY (Mai 2013, black), H2 ETMY (Mai 2013, pink), H1 ETMX (last week during alignement, cyan) and H1 ETMX (end of last week after alignement, green)

3-b) Pitch to pitch reaction chain comparison between erm model, H1 ETMX (most recent) and H1 ETMY (Mai 2013)

After discution with sus commissioners, the main chain pitch mode is sensitive to d-effective values (distance between center of mass and fiber flexure point). Since the flexure point can move slightly depending on the shape of the fiber, it seems acceptable to have a shift in frequency for pitch.

For the reaction chain, pitch is sensitive to the way cables are wired, and again, it can vary from quad to quad.

ETMX is then approved for phase 2c, and TMSX team can move on with installation