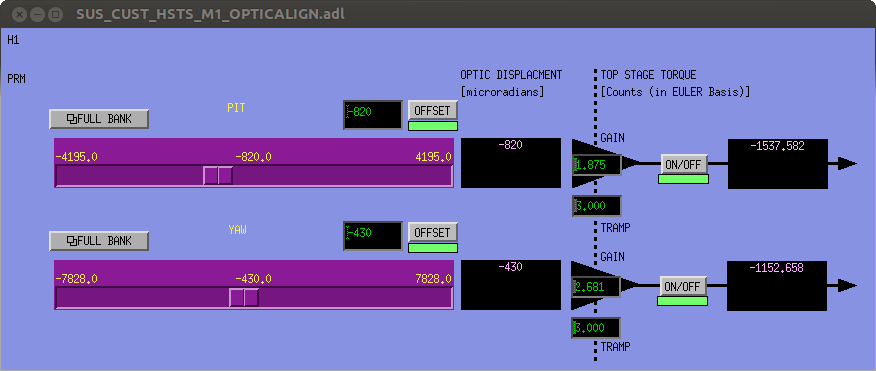

We placed Mode Master downstream of three-mirror Gouy phase matching telescope comprising two tip-tilts and one fixed mirror that is used for REFL WFS. (See the last picture for layout and distances.)

Note that the measured TT1-TT2 distance is about 1cm shorter than nominal described in Sam Waldman's document (http://dcc.ligo.org/T1000247), TT2-M5 distance is about 14mm longer than nominal, both of which should have been quite acceptable.

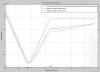

Anyway, we made this measurement and the beam was much smaller than what was expected. The first plot as well as the table below show the measured VS the expected mode profile coming out of HAM1 propagated through the telescope with the measured mirror distances.

|

|

measured, x |

measured, y |

expected |

|

M^2 |

1.04 |

0.98 |

1-ish |

|

Waist radius |

1.38 mm |

1.15 mm |

1.92mm |

|

Waist position (away from MM head into HAM1) |

4.31 m |

4.35 m |

1.78 m |

|

Mode overlap between measured and expected |

0.872 |

0.753 |

1 |

The total mode overlap between the actual beam and what is expected is somewhere between 0.75 and 0.87 (sort of tedious to do the real calculation so I leave it).

The 2nd plot shows that IF the incoming beam from HAM1 is as expected, in order to explain the measured mode the TT1-TT2 distance labeled as delta1 should be shorter by 4.5cm than was measured for X, or by 5.7cm for Y. This is a huge number, there's no way my distance measurement was that much off.

The 3rd plot shows the Gouy shift between TTs (i.e. actuation orthogonality) and WFSs for the WFS sled (i.e. sensing), and it seems like both are quite poor for the measured mode, 26deg for actuation and 35 for sensing are sad though not a complete disaster.

Anyway, since it's hard to imagine that the ROC of TT1 (+1.7m), TT2 (-0.6m) and M5 (+1.7m) are grossly wrong, and since it's hard to imagine that the distance measurement has a 5 to 6cm error, this should mean either (or some) of the followings:

-

T1000247 is wrong about the mode coming out of HAM1.

-

IMC mode is not mode matched to the IFO well.

-

Astigmatism of curved optics at an angle (there are 3 such optics on HAM1, more on HAM2), each has small effect but maybe they add up. Neither Sam nor I have included this.

The third one doesn't sound likely, but neither Sam nor I have thought about this.