Summary: In an attempt to better understand the high magnetic coupling to the test masses, I measured magnetic fields at the locations of the 8 PUM magnets for an isolated reaction mass, the fields around ITMY in situ in BSC1, the moments of the 2 types of magnets, and searched for other possible coupling locations. While I have not been able to account for the high coupling, I did find that large parts of the UIMs and the PUM reaction mass were magnetic. I will try to measure the magnetic moments of these masses when I return.

Gradient scales at the PUM magnets

10 Hz

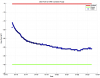

I used a fluxgate magnetometer and measured fields at the positions of the 8 PUM magnets (2 in each flag) for an isolated PUM reaction mass (Figure 1). In the table below the fields B1 and B2 were at sites 2.7 cm apart, close to the separation of magnets in the PUM flag. The measurements were used to estimate how well the paired magnets in each flag could cancel. The last column gives approximate gradients from the field differences for the two sites. The magnets were not in place for the measurements.

|

PUM flag location

|

B1

|

B2 (0.027 meters from B1)

|

B1 – B2

|

B/GradB

|

|

UL

|

1.33E-05

|

1.17E-05

|

1.63E-06

|

2.07E-01

|

|

UR

|

1.09E-05

|

9.43E-06

|

1.45E-06

|

1.88E-01

|

|

LR

|

1.02E-05

|

9.14E-06

|

1.06E-06

|

2.45E-01

|

|

LL

|

1.14E-05

|

1.11E-05

|

3.00E-07

|

1.01E+00

|

At the UL site, I also looked for higher gradients on a smaller scale (smaller movements) and found B/gradB values of 0.012 m for 6mm displacements right at the location of the flag magnet in the AOSEM. Of course the fluxgate’s ability to measure high gradients that extend only over short distances is limited by the scale of the sensor, which is 1.8 cm long. The magnets are 0.6 cm long so they could be subject to localized gradients that would have been averaged down by the fluxgate. For calculations of the magnetic coupling, I halved the 0.12m scale to 0.06 m because of the possibility of more localized gradients.

100 Hz

I also made a couple of measurements at 100 Hz. For a 2.7 cm difference at UL, my estimate of B/gradB was 0.012 instead of the 0.021 at 10 Hz.

Measurements of fields and gradients around the quad in-situ inside BSC1

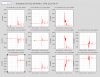

I measured injected magnetic fields around the ITMY quad in BSC1 (Figure 2) in order to make sure that the field at the ITM during my coupling measurements was similar to my estimates made with a magnetometer mounted outside BSC1, under its center. The average of injected field values inside was 37% lower than I estimated from my outside measurement. Thus the coupling should be 37% higher (worse) than I previously reported.

The scale of gradients across the back face of the reaction mass chain were measured to be:

(B/gradB: 5.26 m, 1.10 m, 0.58 m, 0.53 m). These measurements were used to estimate how well magnets at different actuators could cancel. The arm cavity baffle was not installed for these measurements, and the BSC door was open.

Magnet moments

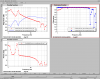

I measured the moments of one large (M0, L1) and one small (L2) magnets using a magnetometer at a distance large compared to the magnet size (Figure 3). For the small magnet I measured 0.013 J/T and for the large one, 0.717 J/T (or Am^2).

Estimates of residual moment from magnets

I used the fields measured at the positions of the 2 magnets in the PUM flags to estimate the residual moment for the pairs in each flag. I also used the larger scale gradients from the in-chamber measurements to estimate how well the different locations would cancel (e.g. how well will UL cancel LR). I estimated a residual moment of 1/3 of the moment of a single one of the 8 magnets, if all magnets were oriented properly, and a residual moment of about twice the single magnet value if one magnet was mis-oriented. For the estimates below of coupling at the UIM, I used the same gradient scales as I measured for the PUM.

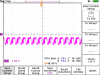

Magnetized 304 steel in the UIM and PUM reaction mass

Figure 4 demonstrates that magnets stick to many parts of the UIMs and PUM reaction masses (L1, R1 and R2). Many of the large parts of the main and reaction UIM, as well as the reaction PUM are called out as 304 or 316 steel (shops choice). The relative permeability of cold worked 304 steel can be several orders of magnitude higher than 316 steel and is reported to reach 10 or 20. So magnets stick to many parts of the UIM and PUM reaction mass, and which parts are magnetic varies with the particular run of parts. About ½ of the volume of the PUM reaction mass in BSC1 is magnetic and at least ½ of the UIM and reaction UIM are as well.

Estimates of coupling from magnets and magnetized 304 steel

I used the measurements of magnet moments and estimates of the residual moments along with the estimated field gradients and moment arms to estimate torques on the PUM and UIM. To compare to the angular motions I observed in the magnetic coupling measurements, I used Mark Barton’s functions for force or torque at the various quad levels to displacement, pitch and yaw of the test mass.

To estimate motion produced by the magnetized 304 steel, I assumed that the parts were magnetized by the large DC field from the earth (I used 3e-5T), giving them a magnetic moment and causing them to couple to the small AC fields: m = chi/mu0 BearthV. This does not include the magnetization from the permanent magnets, but estimates that I have made do not suggest that this could increase the moment by more than a factor of a couple. I used a relative permeability of 10, at the high end of permeability for 304 steel. I will try to measure the magnetic moment of parts directly when I return. I have also not examined the connectors.

|

Coupling

|

Pitch at 10 Hz (radians/T)

|

Yaw at 10 Hz (radians/T)

|

|

Measured coupling

|

2.3 e-6

|

2.2 e-5

|

|

Estimated coupling from UIM magnets, perfectly aligned and (one magnet misaligned)

|

2.7 e-7 (1.8 e-6)

|

1.2 e-7 (7.9 e-7)

|

|

Estimated coupling from PUM magnets, perfectly aligned and (one magnet misaligned)

|

2.1 e-7 (1.4 e-6)

|

8.4 e-8 (5.6 e-7)

|

|

Estimated coupling from 304 steel in UIM

|

5.4 e-7

|

2.4 e-7

|

|

Estimated coupling from 304 steel in PUM reaction mass (R2) to test mass reaction mass (R3), NOTE: not to test mass itself

|

2.0 e-5

|

8.2 e-6

|