Summary: We found that the magnetic coupling to ITMY was about the same when HEPI, ISI and SUS were off and the voice coils were disconnected, suggesting that the coupling was to passive systems such as permanent magnets. We also found that the coupling was about the same at ETMY as at ITMY. Injection experiments suggest that magnetic coupling takes place at multiple levels of the suspension.

We recently found that magnetic injections produced motions of ITMY that, when scaled linearly, suggested that ambient magnetic fields would produce motions that were at least 3 orders of magnitude too large at 11.5 and 60 Hz (here).

Coupling levels similar with HEPI, ISI, and SUS off

This past week, we found that this coupling is not to cables or coils for the active systems. We repeated the injection after disconnecting all SUS cabling to ITMY at the output side of the satellite modules, all ISI actuator cabling at the back of the three coil driver modules, and shut down HEPI. We monitored the effects of the magnetic injection using the optical lever, which we realigned because ITMY was no longer biased. Figure 1 shows that the observed coupling was about the same as when the cables were connected and the ISI and SUS loops were working in the normal OAT configuration. This suggests that, at least at 3.5 Hz, coupling is to passive elements (e.g. magnets) and not to cables or connectors.

Coupling consistent with linearity

We tested for linearity at 3.5 Hz, finding that a 2.98 fold decrease in the injected magnetic field reduced the optical lever signal by a factor of 3.00. The uncertainty, due to background, was a couple of percent, so these results are consistent with linear coupling.

Signal not from coupling at optical lever

To make sure that the optical lever signal was not produced by magnetic field coupling to the optical lever electronics, we set up the injection coils by the optical lever, making the magnetic fields at the optical lever, the cabling, the optical lever electronics, and the I/O chasis, which are set up near the optical lever, orders of magnitude larger than for our injections at BSC8. The 3.5 Hz optical lever signal was much smaller in this configuration, indicating that we had been seeing real motion of the test mass. This observation is supported by the lack of a signal when the laser beam spot is off of the optical lever diode.

Coupling similar at ETMY

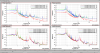

We then moved our injection setup to Y-end and found that coupling to ETMY was similar to that for ITMY. Figure 2 shows the predicted levels of motion from the ambient background for both ITMY and ETMY. To calculate the approximate motion that we observed for out injections, multiply by 1e-4 T/ 3e-11T (injection/ambient) for points up to 11.5 Hz, and 1e-4/5e-9 for the 63 Hz point (used to predict 60 Hz amplitude). The arm cavity was dropping lock about every 20 minutes this week, so we could not integrate for long periods, and we only have arm cavity length points for 2 and 3.5 Hz at ITMY and 2Hz at ETMY.

Coupling seems to occur at multiple levels of the suspension

In an attempt to narrow down the coupling sites, we injected 11.45 Hz signals into the length damping loops of ETMY M0, L1 and L2, and compared the 11.45 Hz actuator injection signal to the 11.5 Hz magnetic injection signal at each of the suspension levels. We reasoned that if the magnetic coupling was mainly at a particular suspension level, e.g., L1, then the actuator injection and the magnetic injection peaks would be most similar at each of the suspension levels when the actuator injection was into the same SUS level that the magnetic injection coupled to. Figures 3 shows BOSEM, AOSEM or optical lever signals at each of the four SUS levels for an H2:SUS-ETMY_L2_TEST_L_EXC injection (20,000 counts) at L2. The figure shows that the relative sizes of the actuator injection and the magnetic injection peaks are different at all of the other levels than they are at the injection level, L2. This suggests that magnetic coupling occurs at levels other than L2. A repeat of this procedure with injections at M0, and L1 also suggested that magnetic coupling was present at multiple levels.

Caveats

1) The test that coupling was not to cables took place at 3.5 Hz at ITMY. The ETMY magnetic coupling at multiple levels of SUS, just discussed, could be explained by coupling to cables, if the coupling mechanism were different at ETMY 11.5 Hz than at ITMY 3.5 Hz. Arguing against this is the very similar coupling levels at 11.5 Hz for ETMY and ITMY (see Figure 2).

2) Linearity was only studied at ITMY at 3.5 Hz, and may not apply to the coupling mechanism at ITMY, 63 Hz, or even at ETMY, 11.5 Hz.

My Suggestions

1) The investigation was hindered by the long integration times required to see the small signal. Increasing the injections to greater than 1e-4 T would help. Also, investigations will become easier as we become more sensitive to motions and when arm locks last longer.

2) 11.5 Hz is, of course, right at the edge of the detection band, so the observations at 63 Hz may be more worrisome. As sensitivity increases, we can investigate the coupling at 63 Hz, which may not be due to the same mechanism as at 11.5 Hz, e.g., may not be linear.

3) ETMY and ITMY both have damping magnets. We should investigate the ECD magnet-free suspensions when they are installed.

4) It may be easier to continue some investigations off-line at, e.g. LASTI, where we might pull magnets etc. and monitor motion using an optical lever.

5) I and others have been considering mechanisms that might enhance coupling. Eddy currents in metal components can convert uniform AC magnetic fields into fields with gradients that I think are proportional to the diameter of the component faces. One possibility is that eddy currents induced in fixed metal components that are near to and about the same diameter as movable permanent magnets are increasing the field gradients that the magnets are subjected to. For example, eddy currents generated by ambient fields in the copper next to eddy current damping magnets may increase the ambient field gradients and the resulting force on the permanent magnets. High field gradients from eddy currents might also defeat attempts to cancel magnetic forces from ambient fields by stacking magnets in opposite pole orientations.

Robert Schofield, Maggie Tse, Richard McCarthy