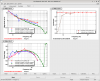

We had several locklosses from DRMI in the last hour. PRCL was oscillating at just above 100 Hz, because it's gain was too high. I reduced the PRCL1 gain from 8 to 4. I then remeasured once DRMI was transitioned to 3F, the gain was now too low by a factor of 2, so I set it back to 8.

I won't make this change in the guardian, because I don't know if this is consistent or not.

My notes on this PRCL motion before locklosses:

I have found multiple other times where PRCL has had rapid motion like seen in the above alog. Screen shots included below.

This is just in ISC state 101 so far.

But it does seem like this started on the 23rd, as I have not been able to find a time when this happened before April 23rd.

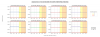

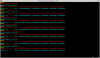

List of Locklosses that have happened in ISC state 101

ID GPS UTC guardian state state duration tags analysis status

0 1398722295 1398722295.375 2024-05-02 21:57:57.375000 UTC 101 fail

1 1398342613 1398342613.1875 2024-04-28 12:29:55.187500 UTC 101 INITIAL_ALIGNMENT fail

2 1397959320 1397959320.25 2024-04-24 02:01:42.250000 UTC 101 0:00:52 MAINTENANCE EARTHQUAKE INITIAL_ALIGNMENT analyzed [0.29.1]

3 1397958844 1397958844.0 2024-04-24 01:53:46.000000 UTC 101 MAINTENANCE EARTHQUAKE fail

*4 1397918529 1397918529.375 2024-04-23 14:41:51.375000 UTC 101 analyzing -----------Good Example

*5 1397915450 1397915450.0 2024-04-23 13:50:32.000000 UTC 101 analyzing -----------Good Example

6 1397490602 1397490602.0625 2024-04-18 15:49:44.062500 UTC 101 0:00:12 analyzed [0.29.1]

7 1397351257 1397351257.566406 2024-04-17 01:07:19.566406 UTC 101 WINDY OMC_DCPD REFINED fail

8 1397349619 1397349619.261719 2024-04-17 00:40:01.261719 UTC 101 REFINED WINDY INITIAL_ALIGNMENT OMC_DCPD fail

9 1397333742 1397333742.512695 2024-04-16 20:15:24.512695 UTC 101 0:00:33 WINDY REFINED analyzed [0.29.1]

10 1397226213 1397226213.3125 2024-04-15 14:23:15.312500 UTC 101 INITIAL_ALIGNMENT fail

11 1396929654 1396929654.377441 2024-04-12 04:00:36.377441 UTC 101 REFINED INITIAL_ALIGNMENT fail

12 1396880628 1396880627.856934 2024-04-11 14:23:29.856934 UTC 101 0:00:11 REFINED analyzed [0.29.1]

13 1396751608 1396751608.208984 2024-04-10 02:33:10.208984 UTC 101 REFINED analyzing

14 1396370541 1396370540.857422 2024-04-05 16:42:02.857422 UTC 101 REFINED fail

15 1396368947 1396368941.705078 2024-04-05 16:15:23.705078 UTC 101 REFINED OMC_DCPD fail

16 1396363292 1396363292.875 2024-04-05 14:41:14.875000 UTC 101 FSS_OSCILLATION BOARD_SAT EARTHQUAKE INITIAL_ALIGNMENT fail

17 1396184286 1396184286.200195 2024-04-03 12:57:48.200195 UTC 101

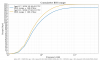

Make Histogram of the following data after excluding DAQ restarts:

['H1:GRD-ISC_LOCK_STATE_N.mean,m-trend']

<H1:GRD-ISC_LOCK_STATE_N.mean (0.0166667Hz, MTREND, FLOAT64)>

lines read from servers: 47066

Number of time values where Query state H1:GRD-ISC_LOCK_STATE_N == state 101 is true: 277

Number of Unique times the channel was in such a state: 149

Length of SCstart: 149 Length of SCstop: 149 length of duration 149

0 1396042620 1396042620 0

1 1396042920 1396042920 300

2 1396095060 1396095060 52140

3 1396098000 1396098000 2940

4 1396133820 1396133820 35820

5 1396165320 1396165320 31500

6 1396184700 1396184700 19380

7 1396200540 1396200600 60

8 1396214760 1396214760 14220

9 1396218300 1396218300 3540

10 1396246980 1396246980 28680

11 1396358340 1396358340 111360

12 1396359600 1396360260 660

13 1396361700 1396361700 2100

14 1396362120 1396363200 1080

15 1396367940 1396367940 5820

16 1396368180 1396368180 240

17 1396368420 1396368840 420

18 1396370160 1396370160 1740

19 1396370460 1396370460 300

20 1396385340 1396385340 14880

21 1396451220 1396451220 65880

22 1396494480 1396494480 43260

23 1396548420 1396548600 180

24 1396549140 1396549320 180

25 1396686480 1396686480 137340

26 1396686780 1396686780 300

27 1396728060 1396728060 41280

28 1396746360 1396746360 18300

29 1396747140 1396747140 780

30 1396749420 1396749420 2280

31 1396752120 1396752120 2700

32 1396769520 1396769520 17400

33 1396773900 1396773900 4380

34 1396774140 1396774140 240

35 1396790760 1396790760 16620

36 1396794540 1396794540 3780

37 1396814460 1396814460 19920

38 1396814760 1396814820 60

39 1396930080 1396930140 60

40 1396930380 1396930440 60

41 1396998480 1396998480 68100

42 1397047080 1397047260 180

43 1397047500 1397047680 180

44 1397144280 1397144280 96780

45 1397146080 1397146080 1800

46 1397146620 1397146740 120

47 1397173920 1397173920 27300

48 1397187300 1397187300 13380

49 1397190360 1397190600 240

50 1397225160 1397225160 34800

51 1397226120 1397226120 960

52 1397229900 1397229900 3780

53 1397292240 1397292300 60

54 1397292600 1397292600 360

55 1397335440 1397335560 120

56 1397346900 1397346900 11460

57 1397354820 1397354820 7920

58 1397357220 1397357220 2400

59 1397370960 1397370960 13740

60 1397458140 1397458140 87180

61 1397458440 1397458620 180

62 1397466240 1397466240 7800

63 1397471460 1397471460 5220

64 1397471760 1397471760 300

65 1397494320 1397494320 22560

66 1397524440 1397524440 30120

67 1397524740 1397524800 60

68 1397526420 1397526420 1680

69 1397538420 1397538600 180

70 1397538900 1397538900 480

71 1397599800 1397599800 60900

72 1397600520 1397600700 180

73 1397601000 1397601060 60

74 1397646900 1397646900 45900

75 1397647140 1397647200 60

76 1397647740 1397647800 60

77 1397662560 1397662560 14820

78 1397663220 1397663220 660

79 1397690400 1397690400 27180

80 1397715900 1397715900 25500

81 1397716260 1397716260 360

82 1397716740 1397716860 120

83 1397718120 1397718120 1380

84 1397720280 1397720280 2160

85 1397720520 1397720520 240

86 1397726160 1397726160 5640

87 1397727180 1397727180 1020

88 1397763780 1397763780 36600

89 1397766480 1397766540 60

90 1397848140 1397848140 81660

91 1397848440 1397848500 60

92 1397852880 1397852880 4440

93 1397853660 1397853660 780

94 1397867760 1397867760 14100

95 1397868720 1397868780 60

96 1397912580 1397912580 43860

97 1397915820 1397915820 3240

98 1397916060 1397916060 240

99 1397918940 1397919000 60

100 1397937540 1397937540 18600

101 1397952300 1397952480 180

102 1397952960 1397952960 660

103 1397956860 1397957040 180

104 1397957280 1397957280 420

105 1397957880 1397957880 600

106 1397958600 1397958780 180

107 1397959680 1397959860 180

108 1397960220 1397960220 540

109 1397976900 1397976900 16680

110 1397977140 1397977140 240

111 1398037920 1398037980 60

112 1398038280 1398038280 360

113 1398081000 1398081000 42720

114 1398194400 1398194400 113400

115 1398195300 1398195300 900

116 1398219480 1398219480 24180

117 1398219780 1398219900 120

118 1398252540 1398252540 32760

119 1398275280 1398275280 22740

120 1398276660 1398276660 1380

121 1398341760 1398341760 65100

122 1398359160 1398359340 180

123 1398360060 1398360240 180

124 1398361020 1398361020 960

125 1398381240 1398381420 180

126 1398382260 1398382440 180

127 1398553560 1398553560 171300

128 1398554100 1398554100 540

129 1398574020 1398574080 60

130 1398574560 1398574740 180

131 1398574980 1398574980 420

132 1398607740 1398607740 32760

133 1398619380 1398619380 11640

134 1398619680 1398619800 120

135 1398620340 1398620460 120

136 1398629940 1398630120 180

137 1398630360 1398630360 420

138 1398661560 1398661740 180

139 1398662160 1398662160 600

140 1398664260 1398664320 60

141 1398708420 1398708420 44160

142 1398709140 1398709140 720

143 1398722220 1398722220 13080

144 1398723240 1398723240 1020

145 1398724620 1398724620 1380

146 1398733740 1398733800 60

147 1398734040 1398734220 180

148 1398734580 1398734700 120

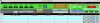

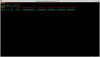

Looking for times where PRCL is above 1000:

['H1:LSC-PRCL_IN1_DQ.mean,m-trend']

<H1:LSC-PRCL_IN1_DQ.mean (0.0166667Hz, MTREND, FLOAT64)>

lines read from servers: 47066

Number of time values where Query state H1:LSC-PRCL_IN1_DQ > state 1000 is true: 11

Number of Unique times the channel was in such a state: 3

Length of SCstart: 3 Length of SCstop: 4 length of duration 4

1396110540 1396110660 120 120

1396117620 1396117800 180 180

1397322360 1397919840 597480

Counting states completed

Times ISC_Lock was in Aquire_DRMI_1F [101]

Start: Stop: Duration: Min: Max:

0 1396110540 1396110660 120

1 1396117620 1396117800 180

2 1397322360 1397322480 120

Maybe be use this channel H1:LSC-PRCL_TRIG_MON to check filter out times.