J. Oberling, R. Crouch

Update on FARO progress so far.

Monday, 2/5/2024

On Monday we tried adding a monument to the existing alignment routine, primarily to see how it worked; we used the same alignment from alog 75706, the one where we had changed PSI-1 and PSI-2 to points but kept BTVE-1 and PSI-6 as spheres (the final 2 pictures from the alog). We used the magnetic nest that we had placed in line with height mark 903 and checked with an autolevel that it was still in line with the height mark (done before the LVEA went Laser Hazard for HAM6 work, nest alignment to height mark was good as found). The FARO gave us X and Y coordinates for the nest, and we used those to convert the local Z coordinate for 903 into a global Z as described in alog 75706. The listed local Z for 903 is -79.9mm (from T1100187), which translates to a global Z for the nest of -79.7mm using the following:

ZG = ZL + (XL * 0.0006195) + (YL * -0.0000125) = -79.9 + (1082.3 * 0.0006195) + (37455.6 * -0.0000125) = -79.7mm [1]

Including the mark in the alignment routine was very straightforward: Open the alignment routine, right click in the window listing the objects used in the alignment and select Add Object, and select the desired point from the drop-down menu. The results of adding this point to the existing alignment routine are shown in the first 2 pictures. As can be seen some got worse and some got better. While it's tempting to say the Build/Inspect results are great, there is one caveat. We checked PSI-6 in the same way we performed the differential height survey between BTVE-1 and PSI-6 in alog 75669 (SMR on the CPN ~1 foot in front of the monument on the vinyl floor, but in line with the X coordinate; we know this isn't exact, but it gives a ballpark) and that found PSI-6 to be -1.1mm from its nominal Z axis coordinate. Another interesting note, notice the measured Z for 903 in the first picture (2nd column on the annotation). When incorporating 903 into the alignment routine, the best the FARO can do is get within 3.5mm of the nominal Z axis coordinate; when 903 is out of the alignment routine, the FARO thinks it's ~4.2mm above its nominal Z axis coordinate. That's... not so good, and an indication of maybe a larger discrepancy in Z coordinates than we initially thought.

Wednesday, 2/7/2024

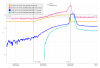

We did the alignment test noted at the end of alog 75706; use a sphere for BTVE-1 and points for PSI-1, PSI-2, and PSI-6. We used BTVE-1, PSI-1, and PSI-2 to perform an initial alignment, then moved the FARO to a spot with direct line of sight to PSI-6. We then probed PSI-6 as a point instead of a sphere and added it to the alignment routine. The third picture shows the results of the alignment routine. We did a Build/Inspect to PSI-6, since we were in a location with direct line of sight, and then moved the FARO back out to the West Bay to do Build/Inspect for PSI-1 and PSI-2; we wanted a line of sight to height mark 902, but this put us out of line of sight to BTVE-1 so we did not do a Build/Inspect to it. The Build/Inspect results are shown in the fourth picture. That is also not so great, and one of the worse Z axis alignments we've seen. This was unexpected given the variations we've seen when using the sphere fit rod.

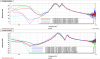

Since we had line of sight to height marks 902 and 903 we used the magnetic nests that we had placed on them to probe them against their nominal coordinates (global Z for 902 was calculated in the same way as we did 903); at this time the LVEA was in Laser Hazard so we were unable to use an autolevel to confirm the magentic nests were still in line with the height marks (903 had been checked on Monday so was likely still good; 902 was last checked roughly a week ago so could have shifted, will check it now that the LVEA is Laser Safe). The results are shown in the fifth picture. There is something fishy here, as the FARO thinks both height marks are higher than our listed coordinates would indicate, by 3 to 4 mm, again indicating that we have some discrepancy between the BTVE/PSI Z axis coordinates and those of the height marks. This was also apparent when we attempted to include both height marks in our Z axis alignment routine. The sixth picture shows the Build/Inspect results if the height marks are included into the Z axis alignment routine with the BTVE/PSI monuments, and the seventh picture shows the Build/Inspect results with the alignment routine considering only the height marks (the check marks next to Use X and Use Y make no difference here, as this portion of the alignment routine has been constrained to only align the Z axis). Including the height marks with the BTVE/PSI monuments results in a bad alignment, especially for PSI-6; the FARO still cannot get a good alignment to 902 and 903. Using only the height marks gets a good alignment to the height marks, but drags the PSI monument way out. This is a further indication of some discrepancy between our BTVE/PSI monuments and our height marks.

Thursday, 2/8/2024

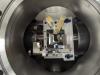

Seeing this potential discrepancy between our BTVE/PSI Z coordinates and our height marks, we set out to try to see where this comes from. Recall, per T1100187 the height marks were laid out in the local LVEA coordinate system, all relative to WBSC2 [0,0,0] (which is the origin of the site coordinate system, both the site global and the LVEA local). The first set of height marks were set using the chamber-side door flange scribe lines; there are 2 scribes on each door flange (one at the 9 o'clock and one at 3 o'clock), for a total of 8 scribe lines per chamber. The 8 scribe lines for WBSC2 were averaged together to produce the Z axis origin, and the height marks were set relative to this. The initial chamber placement was done using the BTVE/PSI monuments, thereby linking them to the height marks. Knowing this, we again used the FARO as an autolevel to perform a differential height measurement between BTVE-1 and height marks 902 and 903. We set the FARO in a location with line of sight to BTVE-1, PSI-1, PSI-2, and both height marks. It was oriented to local gravity and we used the Hubbs CPN (with its 2" vertical offset) to measure a Z coordinate for BTVE-1, PSI-1, and PSI-2, corrected in the -Z direction by 50.8mm to account for the vertical offset of the CPN. These Z coordinates are relative to FARO's initial coordinate system, but since we're doing a differential height survey this doesn't matter. We then did the same measurement with the height marks, and calculated a measured deltaZ between our height marks (and a repeat of PSI-1 and PSI-2) and BTVE-1. Results, all units in millimeters:

- Measured heights

- BTVE-1: -591.2

- PSI-1: -1416.1

- PSI-2: -1417.4

- 902: +406.2

- 903: +389.3

- Delta Z

- deltaZPSI-1: -824.9

- deltaZPSI-2: -826.2

- deltaZ902: +997.4

- deltaZ903: +980.5

Interesting here is that our deltaZ for PSI-1 and PSI-2 is different than our last measurement in alog 75669, both by +0.2mm. This is a very small difference so not very worrying, and is likely caused by how the CPN sits in the BTVE punch (since the punch is not directly on the top of the domed monument, the CPN does have a slight wiggle to it; we tested this by wiggling the CPN and watching the measured Z coordinate, it does move but by only a couple tenths of a mm). The deltaZ between marks 902 and 903 comes out at +16.9 mm w.r.t. 902; the theoretical difference is +17.2mm w.r.t. 902, so pretty close.

Moving on, we can convert our global Z for BTVE-1 into a local Z using the opposite direction cosines used above in [1] (from Section 2 of T0900340 XL = XG and YL = YG). This looks like:

ZL = ZG + (XG * -0.0006195) + (YG * 0.0000125) = -1057.2 + (0.0 * -0.0006195) + (46000.0 * 0.0000125) = -1056.6 mm [2]

With a local Z for BTVE-1 we can then calculate the theoretical deltaZ to height marks 902 and 903 and compare to our measured (all units in millimeters):

| |

Theoretical |

Measured |

Difference |

| deltaZ902 |

+993.9 |

+997.4 |

+3.5 |

| deltaZ903 |

+976.7 |

+980.5 |

+3.8 |

So according to the FARO these 2 height marks are several mm higher than our listed coordinates indicate, at least w.r.t. BTVE-1. As a quick and dirty test we have line of sight to height mark 504, which sits on the north wall of the West Bay, near the main crane parking spot. We do not have a nest on this mark (would need to glue one, the walls aren't magnetic), but roughly holding the SMR center on the height mark we were able to get a ballpark Z and compare it to BTVE-1. This indicated that mark 504 is very approximately +2.9mm from where T1100187 says it is. Combined with the discrepancies measured for 902 and 903, this is worrying. Where is this coming from? Several possibilities come immediately to mind:

- WBSC2 was incorrectly placed in Z w.r.t. the BTVE/PSI monuments

- The height marks were incorrectly placed w.r.t. WBSC2 Z=0

- We're seeing years of error stack ups between height marks derived from other height marks derived from other... derived from WBSC2 Z=0

- We're doing something wrong in using the FARO to do this differential height measurement

- Some combination of 2 or more of the above

Our next step is to try to figure out the source of this discrepancy. The obvious way is to check WBSC2 Z=0 against the existing height marks to see how they register to each other using the 8 door flange scribe lines on WBSC2. This is much easier said than done, however. There is a lot of infrastructure blocking lines of sight, including beam tubes and other BSC chambers, electronics racks, TCS/HWS tables, HEPI piers, and cabling that was not present when WBSC2 Z=0 was established during site construction. So in reality our next step is to figure out how to figure out the source of this discrepancy. Stay tuned, more to come.

Finally adding the pictures to this alog.

And a link to the Google doc for making the BRS changes.

https://docs.google.com/document/d/1XBH-TVwQ3JC8rjLGXUg-LDZKzHxaTuKBC3_-B_fWWAk/edit#heading=h.7b9gxgqfvsr0