Jason Ryan Jenne Daniel

We reduced the PSL power after the amplifier and before the AOM by a factor of 2.3. We then re-adjusted the power into the IMC to get back to 2W. This reduced the IMC reflected light power by ~2.7. This seems to strongly indicate that we have a heating issue in the path from the PMC to the polarizer. The following tests were run:

- Normal PSL setup (first screen shot)

- PMC input power reduced: the power was reduced with the waveplate before the ISS EOM (which is before the PMC)

- EOM input power reduced: the power was reduced with the waveplate between the PMC and the EOM

- Same as above but with enough power to lock th einterferometer at full power. The maximum IMC input power is now 70W.

| Normal PSL setup |

PMC inp |

EOM inp power reduced |

EOM inp power reduced |

|

|---|---|---|---|---|

| EOM power (W) | 115 | 50.8 | 49.6 | 87 |

| IMC input power (W) | 2.01 | 2.05 | 2.02 | 2.04 |

| IMC REFL power (mW) | 1.10 | 0.405 | 0.49 | 0.64 |

- During this time with reduced power in the PMC, PMC refl was 12.93 W and PMC trans was 44.86W (28.8% is the ratio), with PSL air conditioner on.

- Today, with normal power in the PMC,PMC refl is 24.6W, trans is 103.7W (23.8% reflected) with the air conditioner on trans is 104.48 (23%)

- After the 14 hour, 60W lock where we saw degredation in the IMC visibility, the PMC refl was 24.7W trans was 104.9W, (23.5%)

- Immediately after the power outage, PMC refl is 26.7W, while trans is 103.1W, (25.9%), then things improved (maybe when Ryan moved pico's) to 23.3%

- before the power outage, the PMC refl was 24.0W, trans was 105.7W (22.7%)

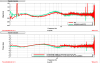

- The PMC refl has been slowly increasing for a while, Feb 26 2025 it was 22.2W, with 106.6 W trans (20.8%)

Attaching a trend showing that the PMC refl has been increasing gradually since Feb, and that there was a jump at the time of the power outage.

When the power into the PMC was low, the mode matching was worse, this is probably expected due to thermal lensing in the PMC.

Elenna, Sheila

Before the power outage, IM4 trans was 93% of the IMC input power. Yesterday, we had 90% of IMC input power at IM4 trans. Today after lowering the power through the EOM, we have 91%.