Marc, Oli

In 87713 it's noted that some of the strange behavior we've been seeing with the locks seem to be related to the ETMY L2 stage. The ETMY L2 satamp was swapped out on Oct 14th from S1100137 to S1100127 as part of the ECR E2400330 upgrade (87469). So, even though we were seemingly doing fine with this ETMY L2 satamp, we decided to swap it out this morning to see if that is the cause of our issues. Coincidentally, the spare satamp that we have available that was modified for ECR E2400330 and that Jeff had characterized was the satamp that had come from ETMY L2, S1100137. So we decided to put that one back in - it was fine before, although it obviously has now been modified for the satamp upgrade. So it's not been swapped back to exactly what it was before, but this is the closest we can get!

Marc and I took S1100137 down to EY and swapped out S1100127 with S1100137. I edited the fitresults file for S1100137 to work for ETMY L2 and replaced the previous OSEMINF 5.3:0.1 compensation filters to be the best possible compensation filters for this new satamp.

Updating compensation filters

$ py satampswap_bestpossible_filterupdate_ECR_E2400330.py -o ETMY_L2

All updated filters grabbed for ETMY

ETMY L2 UL compensation filter updated to zpk([5.25],[0.0959],1,"n")

ETMY L2 LL compensation filter updated to zpk([5.21],[0.0953],1,"n")

ETMY L2 UR compensation filter updated to zpk([5.18],[0.0949],1,"n")

ETMY L2 LR compensation filter updated to zpk([5.21],[0.0955],1,"n")

write /opt/rtcds/userapps/release/sus/h1/filterfiles/H1SUSETMY.txt

Done writing updated filters for ETMY

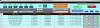

Swap timeline

| Date |

Serial Number |

Whitening zp |

| Before Oct 14th 2025 |

S1100137 |

10:0.4 |

| Oct 14th 2025 |

S1100127 |

5.3:0.1 |

| Oct 24th 2025 |

S1100137 |

5.3:0.1 |

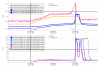

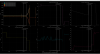

Satamp characterization data

Here's the characterization data and fit results for S1100137, assigned to ETMY L2's ULLLURLR OSEMs.

This sat amp is a UK 4CH sat amp, D0900900 / D0901284. The data was taken per methods described in T080062-v3, using the diagrammatic setup shown on PAGE 1 of the Measurement Diagrams from LHO:86807.

The data was processed and fit using ${SusSVN}/trunk/electronicstesting/lho_electronics_testing/satamp/ECR_E2400330/Scripts/

plotresponse_S1100137_ETMY_L2_20251020.m

Explicitly, the fit to the whitening stage zero and pole, the transimpedance feedback resistor, and foton design string are:

| Optic |

Stage |

Serial_Number |

Channel_Number |

OSEM_Name |

Zero_Pole_Hz |

R_TIA_kOhm |

Foton_Design |

| ETMY |

L2 |

S1100137 |

CH1 |

UL |

0.0959:5.25 |

120.875 |

zpk([5.25],[0.0959],1,"n") |

| |

|

|

CH2 |

LL |

0.0953:5.21 |

121.625 |

zpk([5.21],[0.0953],1,"n") |

| |

|

|

CH3 |

UR |

0.0949:5.18 |

121.625 |

zpk([5.18],[0.0949],1,"n") |

| |

|

|

CH4 |

LR |

0.0955:5.21 |

121.5 |

zpk([5.21],[0.0955],1,"n") |

The attached plot and machine readable .txt file version of the above table are also found in ${SusSVN}/trunk/electronicstesting/lho_electronics_testing/satamp/ECR_E2400330/Results/

2025-10-20_UKSatAmp_S1100137_D0901284-v5_fitresults.txt

Per usual, R_TIA_kOhm is not used in the compensation filter -- but after ruling out an adjustment in the zero frequency (by zeroing the phase residual at the lowest few frequency points), Jeff nudged the transimpedance a bit to get the magnitude scale within the ~0.25%, shown in the attached results. Any scaling like this will be accounted for instead with the absolute calibration step, i.e. Side Quest 4 from G2501621, a la what was done for PR3 and SR3 top masses in LHO:86222 and LHO:84531 respectively.