Follow up to Oli's measurements in [LHO: 87363 LHO: 87611].

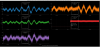

We did the fitting for the SR3 OSEM estimator with the M1 drive measurements from today plus the Suspoint measurements from two weeks ago.

The plant is not nearly as reciprocal as the PR3 plant, I wonder what that means.

The fits had to be obtained by tweaking over the PR3 OSEM estimator model posted in [LHO: 87593]. This worked really fast, and produced very clean results. I think we might use this method as a way to retune the estimators in the future.

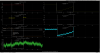

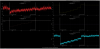

The .pdf attached has the image of the Estimator L/P models for bookkeeping.

The fits are contained in fits_H1SR3_LP-2025-10-07.mat have been uploaded to the SVN under revision 12740 to

(svnroot)/sus/trunk/HLTS/Common/FilterDesign/Estimator.

Here are the ZPKs for the model

_____________________________________________________________________________

SUSPOINT TO M1

Suspoint L to M1 L fit

zpk([0,0,-0.06-4.33i,-0.06+4.33i,-0.051-7.177i,-0.051+7.177i,-0.089-15.255i,-0.089+15.255i],[-0.073-4.136i,-0.073+4.136i,-0.07-4.666i,-0.07+4.666i,-0.071-9.92i,-0.071+9.92i,-0.155-18.168i,-0.155+18.168i],-0.001)

Suspoint L to M1 P fit

zpk([0,0,0.935-6.789i,0.935+6.789i,-1.049-6.865i,-1.049+6.865i,-1.085-18.474i,-1.085+18.474i,0.833-18.561i,0.833+18.561i],[-0.078-4.113i,-0.078+4.113i,-0.058-4.655i,-0.058+4.655i,-0.071-9.916i,-0.071+9.916i,-0.165-13.116i,-0.165+13.116i,-0.221-18.058i,-0.221+18.058i,-0.053-21.596i,-0.053+21.596i],0.383)

Suspoint P to M1 L fit

zpk([0,0,-0.103-4.364i,-0.103+4.364i,-0.095-9.007i,-0.095+9.007i,-0.071-17.115i,-0.071+17.115i],[-0.071-4.094i,-0.071+4.094i,-0.055-4.64i,-0.055+4.64i,-0.062-9.948i,-0.062+9.948i,-0.158-18.146i,-0.158+18.146i],0)

Suspoint P to M1 P fit

zpk([0,0,-0.002-4.162i,-0.002+4.162i,0.006-4.65i,0.006+4.65i,0.036-5.615i,0.036+5.615i,-0.011-9.179i,-0.011+9.179i,-0.065-9.837i,-0.065+9.837i,-0.052-14.212i,-0.052+14.212i,-0.017-21.873i,-0.017+21.873i],[-0.06-4.105i,-0.06+4.105i,-0.01-4.178i,-0.01+4.178i,-0.02-4.629i,-0.02+4.629i,-0.028-4.68i,-0.028+4.68i,-0.019-9.793i,-0.019+9.793i,-0.045-9.975i,-0.045+9.975i,-0.139-13.128i,-0.139+13.128i,-0.041-21.608i,-0.041+21.608i],-0.001)

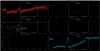

M1 DRIVE TO M1

M1 drive L to M1 L fit

zpk([-0.067-4.297i,-0.067+4.297i,-0.003-5.174i,-0.003+5.174i,-0.024-12.283i,-0.024+12.283i],[-0.064-4.12i,-0.064+4.12i,-0.057-4.635i,-0.057+4.635i,-0.072-9.904i,-0.072+9.904i,-0.155-18.168i,-0.155+18.168i],0.136)

M1 drive L to M1 P fit

zpk([1.502-5.563i,1.502+5.563i,-1.589-5.824i,-1.589+5.824i,-14.284,14.718,1.462-17.431i,1.462+17.431i,-1.276-17.775i,-1.276+17.775i],[-0.068-4.121i,-0.068+4.121i,-0.063-4.638i,-0.063+4.638i,-0.072-9.905i,-0.072+9.905i,-0.158-13.118i,-0.158+13.118i,-0.163-18.132i,-0.163+18.132i,-0.056-21.582i,-0.056+21.582i],0.078)

M1 drive P to M1 L fit

zpk([1.399-5.266i,1.399+5.266i,-1.594-5.6i,-1.594+5.6i,2.034-16.482i,2.034+16.482i,-2.192-17.091i,-2.192+17.091i],[-0.073-4.113i,-0.073+4.113i,-0.06-4.63i,-0.06+4.63i,-0.068-9.924i,-0.068+9.924i,-0.163-13.118i,-0.163+13.118i,-0.143-18.158i,-0.143+18.158i,-0.072-21.583i,-0.072+21.583i],-25.295)

M1 drive P to M1 P fit

zpk([-0.075-4.398i,-0.075+4.398i,0-5.423i,0+5.423i,-0.068-9.979i,-0.068+9.979i,-0.002-20.622i,-0.002+20.622i],[-0.069-4.109i,-0.069+4.109i,-0.051-4.632i,-0.051+4.632i,-0.076-9.938i,-0.076+9.938i,-0.164-13.126i,-0.164+13.126i,-0.074-21.58i,-0.074+21.58i],76.066)