We continue the study of 34863 to explore what effects can differential ITMs cause, as motivated by the high absorption point on ITMX reported in 34853 and 34900.

This time in addition to differential thermal lenses, we also added ITM losses into consideration.

Some key messages from the simulations are:

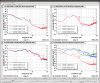

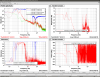

1. The carrier build-up in the PRC is sensitive to losses (apparently), but not to the differential lensing. The RF9 build-up is more sensitive to differential lensing effects than the carrier.

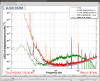

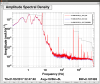

2. The DARM cavity pole is NOT sensitive to ITM losses, but can be changed by differential lensing. See the first plot.

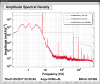

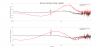

3. The SRM alignment signal is sensitive to differential lensing, but NOT to ITM losses. See the second plot.

=========================================================================

Some details:

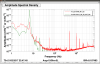

We start from the Finesse input file T1300904, but changed the ITMX and ITMY losses each to 75 ppm, so that the carrier gain in PRC is 40. We also reduced the DARM LSC locking point to account for the losses. The SRC gouy phase corresponding to that file is 20 deg.

We first computed the DARM transfer function (ETM diff phase -> field leaving from the AS port) for a set of extra ITMX lensing, while fixing ITMX loss = ITMY loss = 75ppm. The poles were recorded and fitted with a quadratic function.

Then we fixed ITMY loss = 75 ppm but increase ITMX loss from 75 ppm to 95 ppm. We used two ITMX lensing setting, one with no extra ITMX lensing, one with extra 100 km lensing. For a given diff lensing setting, increase ITMX loss caused the carrier gain dropped from 40 to 36, as expected. At the same time the DARM cavity pole changed by no more than +- 1 Hz. On the other hand if we held loss fixed, changing ITMX lens had tiny effect on the carrier PR gain, but it affected the RF9 build up.

For SRM sensing, there was essentially no effects due to extra differential losses, as shown in the second plot for an extra ITMX lens of f=100 km, SRC gouy phase = 20 deg, and ITMX loss = 95 ppm (blue dashed) or 75 ppm (yellow dotted), and ITMY loss = 75 ppm.

So a possible scenario suggested by the simulations so far might be: when the ifo was cold, we had okay PR gain and SRM sensing. As it being heated up, the high absorption point caused both more losses (which degraded the PR gain) and extra lens (which affected SRM sensing). According to the simulation, we might also expect some drop in DARM pole. Is this observed in reality?