Kiwamu I, Jeff K, Darkhan T,

Overview

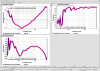

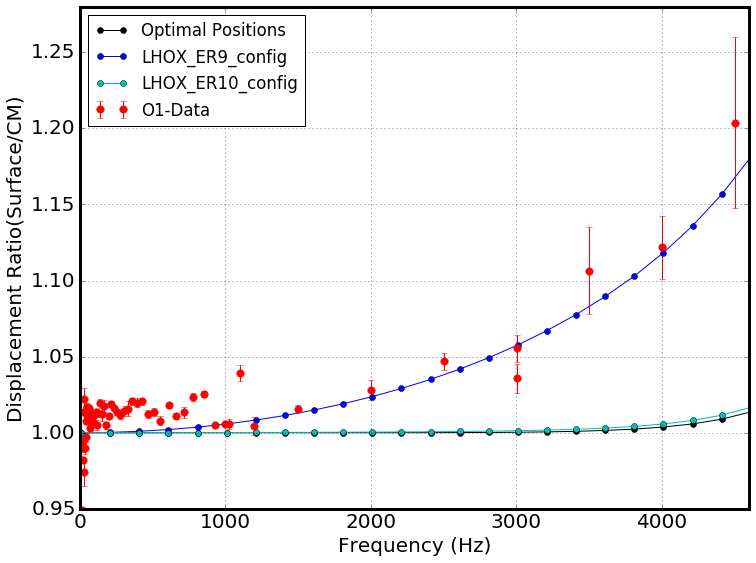

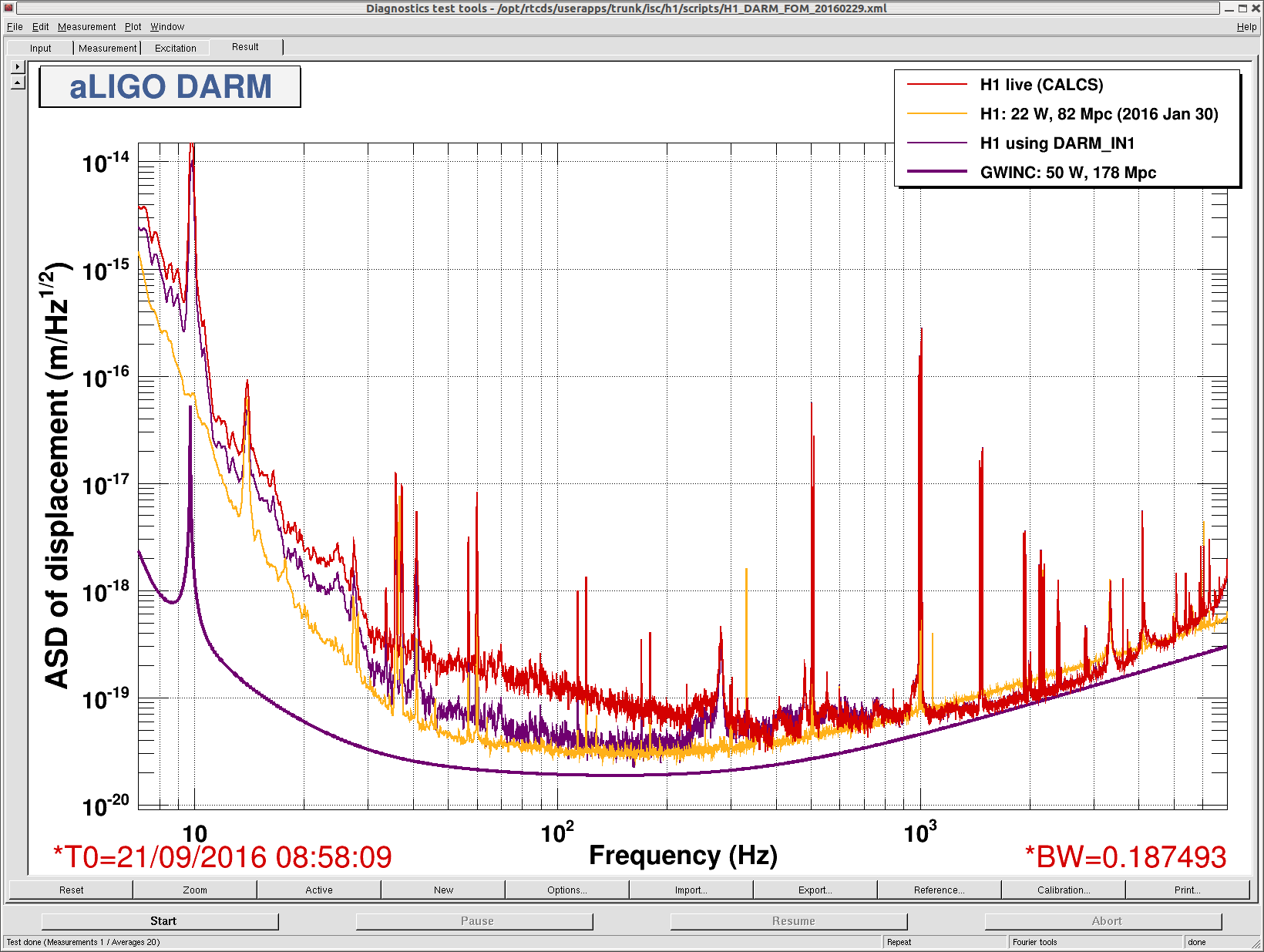

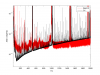

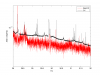

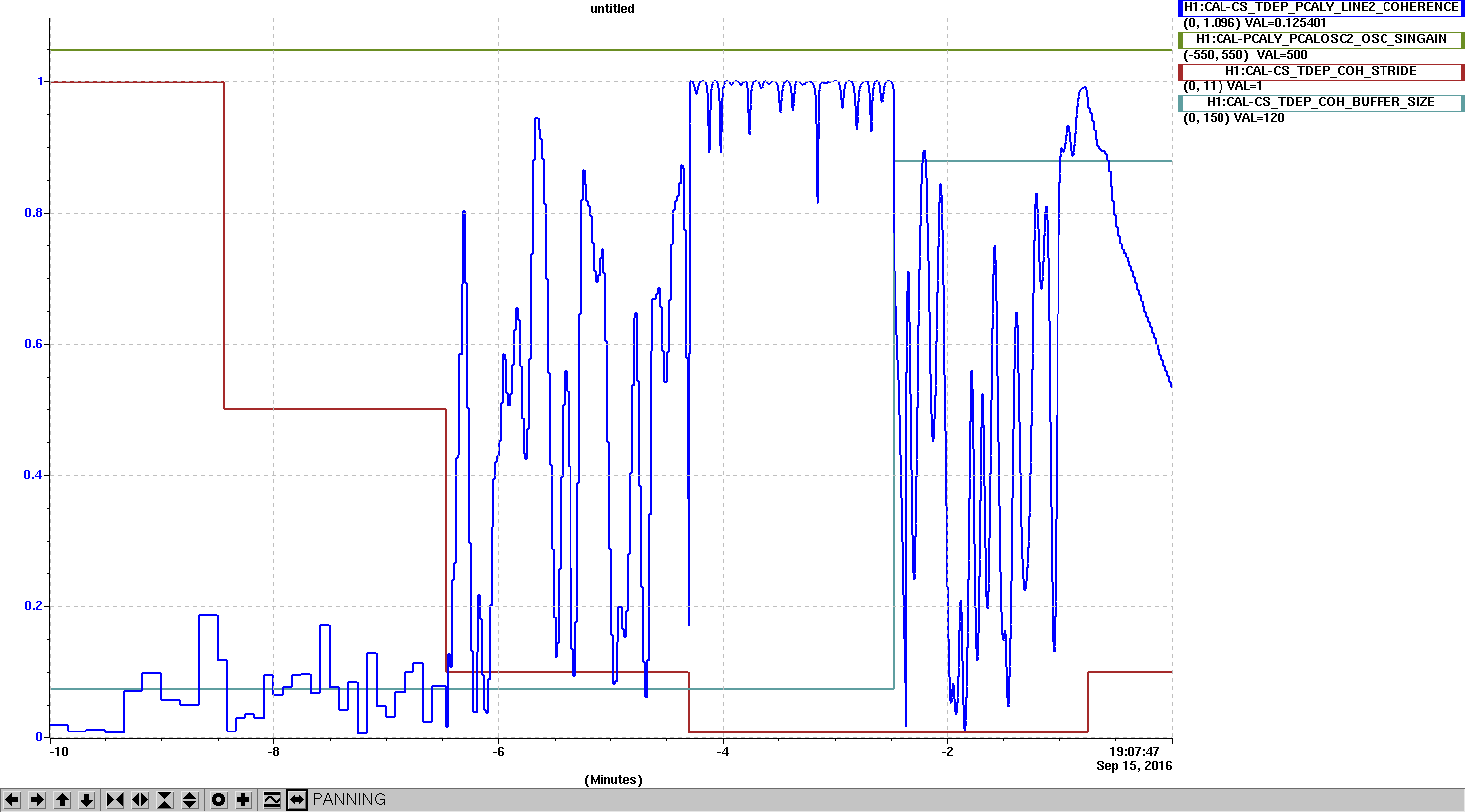

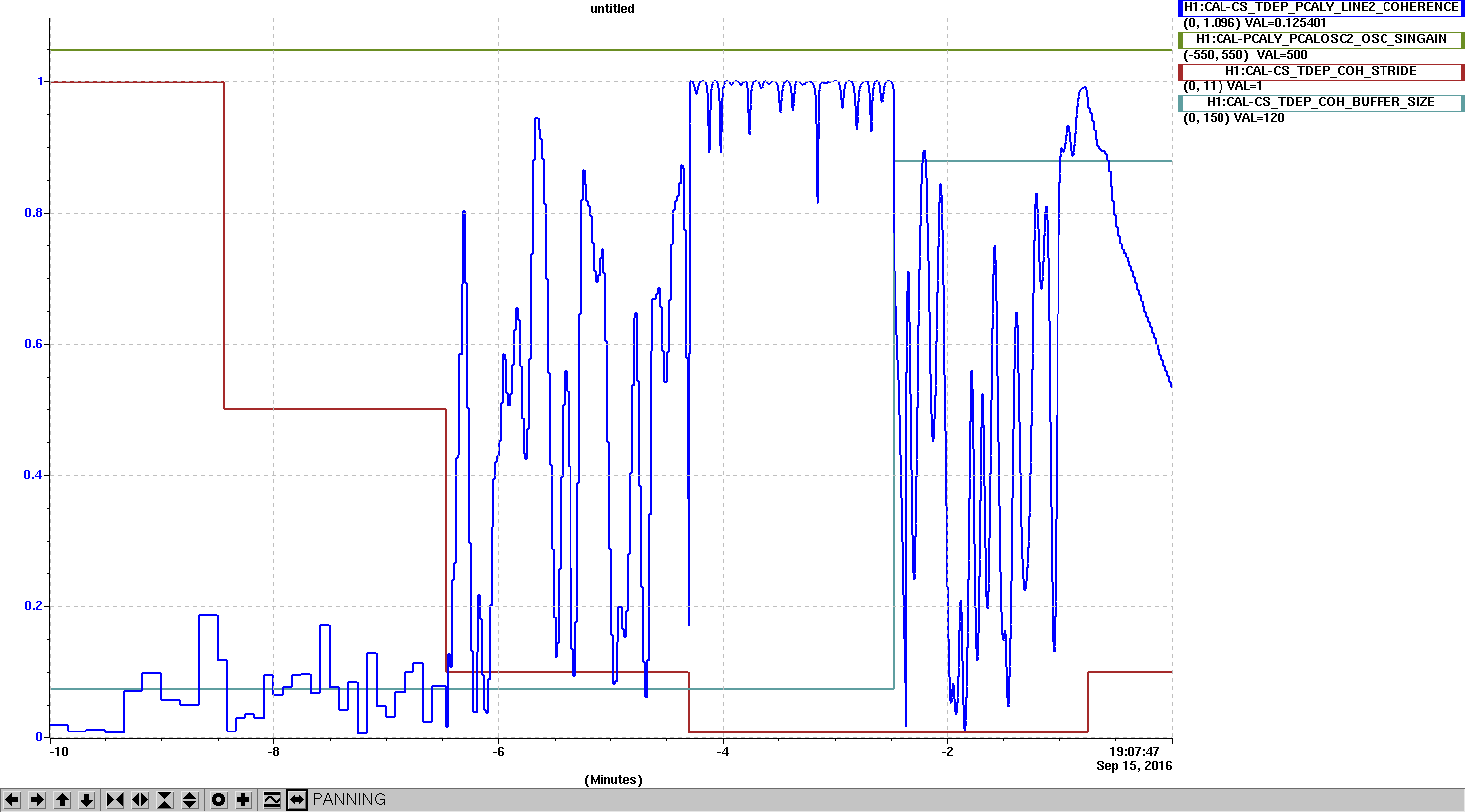

Today we looked at the calibration line coherence values calculated in the front end. We discovered that in the front-end model with the currently used averaging parameters the coherence value is updated once every 10 seconds (first 1.5 minutes in Fig. 1).

We propose modifying the averaging code to improve coherence calculation and avoid potential aliasing (see details).

Details

A front-end model that calculates coherence uses N data points taken every Scycles computational cycles to calculate cross-spectral density of the signals. Scycles is controlled by an EPICS record $(IFO):CAL-CS_TDEP_COH_STRIDE (or simply STRIDE): Scycles = FE_RATE * STRIDE. There are drawbacks associated with this approach:

-

New coherence value will appear every

STRIDE seconds;

-

Skipping data points will produce aliasing.

We can deal with the first problem listed above by reducing STRIDE. On Fig. 1 we show coherence values for N = 10 and STRIDE set to 10, 5, 1, 1/16 and again 1. Notice that this test was done when the IFO was not locked, thus we do not expect a coherence of ~1. When STRIDE is set to 1/16, we can see that the number of averages must be increased in order to include actual fluctuations in the signals (in the last 2.5 minutes N = 120).

Fig. 1

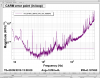

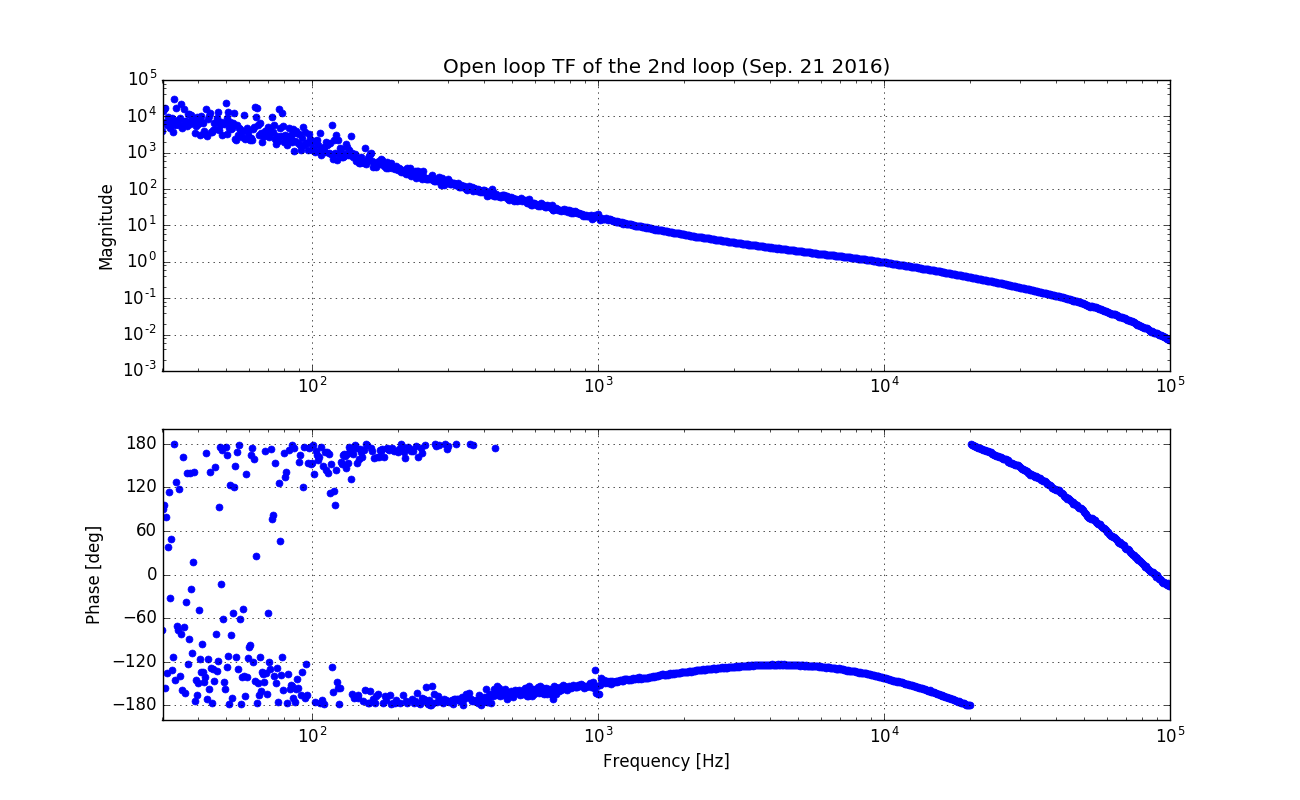

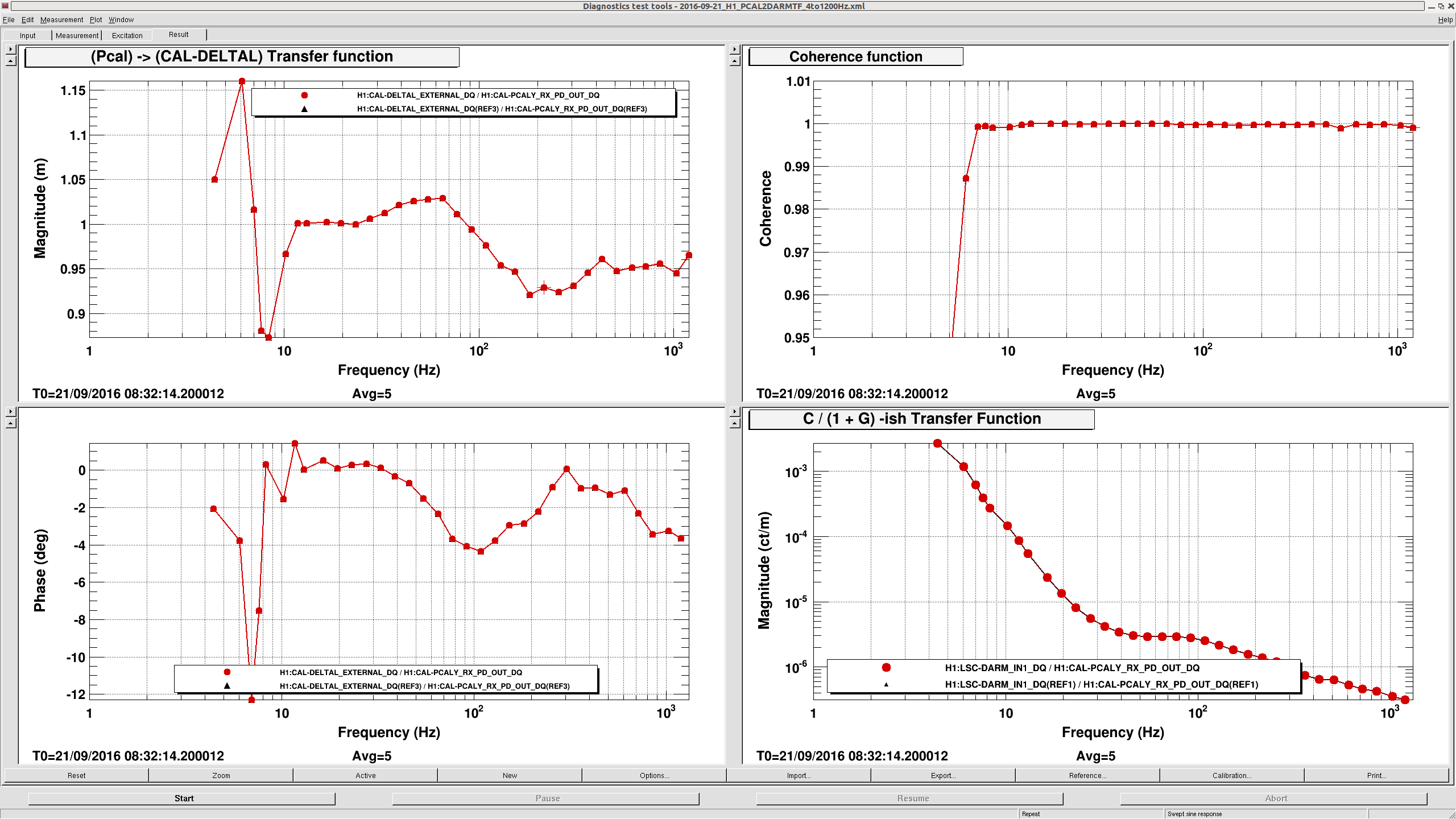

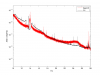

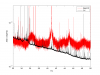

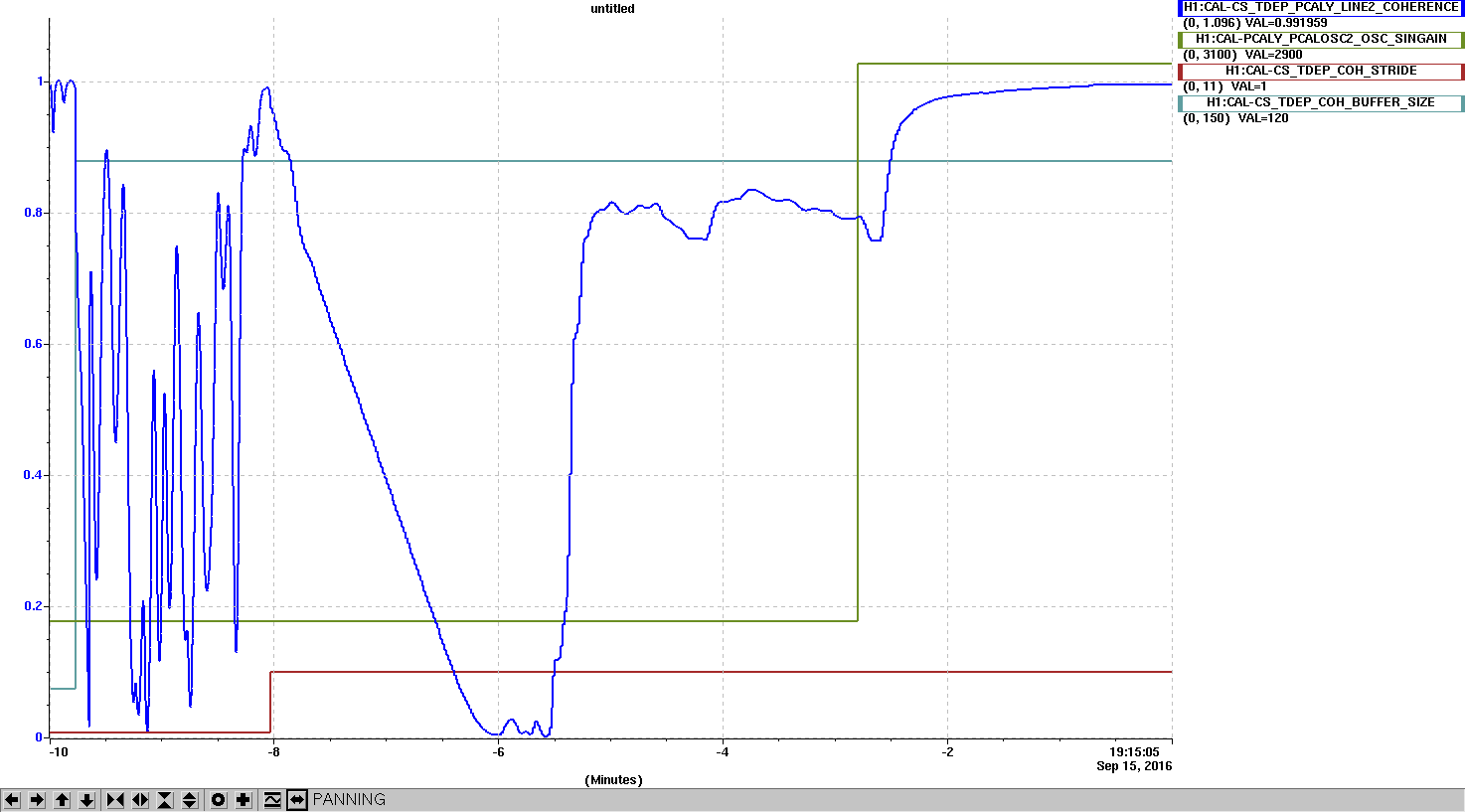

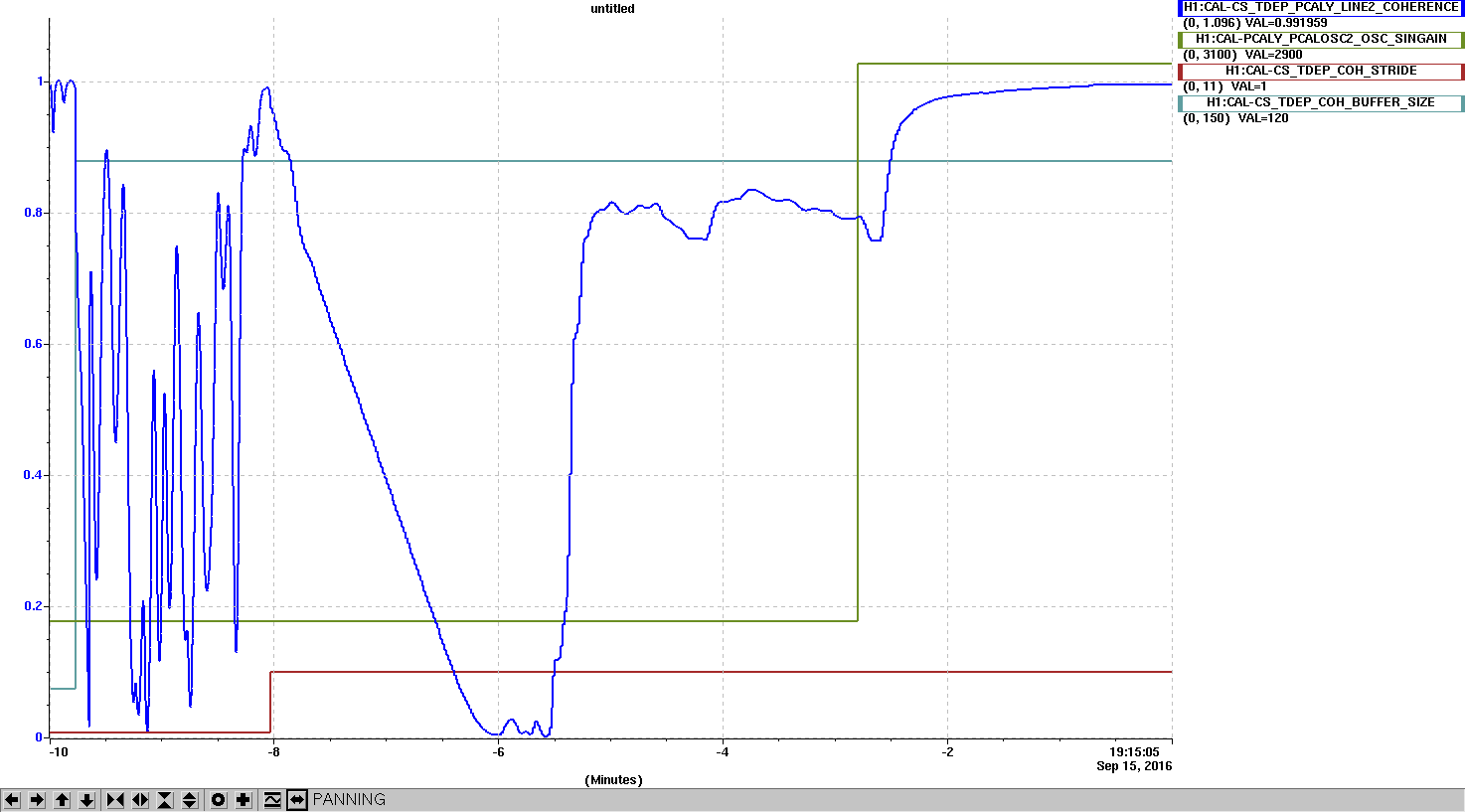

Several minutes later IFO locked (at t = -5 in Fig. 2) and the coherence became ~0.8. After we set the line amplitude to its nominal value we got coherence of ~1.

Fig. 2

Next, to avoid aliasing we should use all data points (equivalent to setting STRIDE = 1/FE_RATE in the current code) and increase N accordingly. Thus to integrate over 10 seconds and avoid aliasing the current code will require O(FE_RATE * 10) = O(160k) operations per cycle and a buffer for 160k values, which is unnecessary expensive.

A following minor modification of the averaging code can solve the issue described above. Instead of adding every Scycles'th data point into the averaging buffer, we could insert an average of Scycles values. E.g. buffer_and_average() can be modified as follows:

...

static int mini_sum = 0;

...

//Increment cycle count

mini_sum += data;

cycle_counter++;

if (cycle_counter >= cycles_between_data) {

buffer[current_pointer] = mini_sum / ((double) cycles_between_data);

current_pointer++;

cycle_counter = 0;

mini_sum = 0;

}

...

With this modification and N = 160, STRIDE = 1/16 (Scycles = 1024), the coherence will be calculated with 10 second integration and will require O(160) operations per cycle, and the coherence value will be updated every 1/16 of a second.