WP6232 Upgrade frame writers

Jonathan, Jim B, Dave:

h1fw2 was running with close to the new code, it was upgraded to add the md5 filename change only. Quickly following h1fw0 and h1fw1 were upgraded to the latest code. I am updating the DAQ MEDM to show the new diagnostic md5 check sum data.

WP6217 ISI frontend code upgrade

Hugh, Jim B

All ISI models were restarted with new code

WP6227 HEPI frontend code upgrade

Hugh, Jim B

All HEPI models were restarted with new code.

WP6235 PSL-DBB jitter feed-forward to LSC

Daniel, Gabrielle, Dave:

New code on the h1psldbb exports the jitter signal as a 64kHz Dolphin channel. The h1lsc model uses this feed-forward data. Change added a 16kHz LSC DQ channel to the commissioning frame.

WP6242 Migration of virtual machines to proxmox

Carlos

Old vmware virtual hosts were migrated to the new Proxmox system.

WP6236 SUS ITMX.ETMX model changes for HWWD install

Fil, Richard, Jim B, Dave

sister wp to 6234. The ITMX and ETMX hardware watchdogs were install. The h1susitmx, h1susetmx models were modified to read the HWWD status via the binary input feed from these chassis. Since we are not controlling these units, I did not put in the binary output logic.

WP6229 h1tcscs model change for SIM parts

Kiwamu, Dave

A new h1tcscs model was installed. We verified that the TCS CO2 chillers behaved correctly on loss of temperature control voltage.

WP6231 GDS-DMT upgrade

team-GDS

Code was upgraded, no impact was seen from the control room

WP6239 PSL-ISS model change

Daniel, Dave

New h1psliss model was installed. This was done at the same time as the h1psldbb change.

WP6240 Beckhoff Slow Controls change

Daniel, Dave

Daniel installed new PLC code. I updated the DAQ INI files, the target autoBurt.req files and the Beckhoff SDF monitor files.

WP6238 CAL-CS model change

Darkhan, Jeff K, Dave

a new h1calcs model was installed.

DAQ restarts

Dave:

The DAQ was restarted several times today to support the above work.

(note we did not get to removing h1ldasgw2 WP#6237, will defer this to later in the week)

That's a bit concerning and not something that I believe we've seen (other than on this one system recently). Certainly possible that it's an air bubble. We'll need to watch this because if the flow sensor causes it to trip out then we will start having down time on the laser. Are there any bubbles visible in any of the tubing or do you think these are getting trapped at some high point in the system? The highest point overall should be up at the chillers, but there will be other local high points such as on the table.

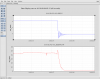

The trend suggests that the flow rate only went to 0 for 3 seconds then made its way back up. Bubble does sound reasonable.

There look to be some regular dips in flowrate, perhaps also bubble related. Might be easier to see in non-trended data how long and deep these dips are.

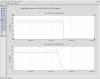

I took a 30 second full data trend from the trip, also including the interlock signal. As can be seen the flow rate is not at its usual value of ~3.0 gpm for approximately 10 seconds. Interestingly, the interlock does not trip until the flow has been below nominal for ~3 seconds. Is this the expected behavior of this interlock?

There is a low pass filter on the input, so yes that's expected behavior. I am surprised that it goes negative though - this should be linear in current from the flowmeter which makes me think it can't go negative without the flowmeter running backwards.