- I put BRS to Very Windy this morning after the meeting

- JimW is modifying guardian to incorporate stage2 code

- current state is Earthquake v3, which also has the BRS not in use

- will switch back to Windy when the site is clear

It seems that since the last power glitches, the DBB is back to operational status... hmmmm. That is to say, before the power glitches it was unusable due to the mysterious tripping of the (dbb) interlock when trying to open the beam path into the box. In the past week I've been trying to get good measurements. This was a abit daunting due to the ISS 3rd loop work that was breaking the IMC lock consistently and yanking on the LASER frequency. Below is what I could muster over the course of a couple of days. ISS_RPN will come later as Peter is currently in the enclosure and working on it.

Comments:

RPN - 35W path looks suspiciously good accross the spectrum by a factor af a few...hmmm? 200W path looks tyo be below requirement from 2Hz to ~25Hz and then above to about a factor of a few through high(er) frequencies.

FRQ - 35W path is quite noisy at low freq (below 15Hz). Other than that the rest looks good save for the usual resonances. 200W path looks ok across the spectrum except for the usual resonances.

PNT - 35W path pointing looks pretty good. 200W path shows seperation of the 1x/y and 2x/y by a factor of a couple.

MSC - 35W path shows TEM 20 +02 an order of magnitude higer than reference. 200W path shows TEM 02+02 mode higher by a factor of a couple.

...and this should wrap it up.

Morning Meeting:

FRS: reviewed

Currently: no locking with Peter in the PSL modifying the ISS beam path

SEI - JimW loading new code into the SEI guardian

Fire Department here to test the fire hydrants - should be here most of the morning, but probably not this afternoon.

Activities:

As of 17:45:

Sheila, Kiwamu, Evan, Matt, Lisa, Jenne, Corey

Tonight the locking has been stable enough that we were able to try several low noise steps. We ended up with a range of about 20 Mpc, and were locked for 3.5 hours.

I used the 332 Hz and 1 kHz pcal lines to update the calibration front-end values for the DARM gain and pole. With these new values, we see that the DARM sensitivity is below the O1 sensitivitiy in the few kilohertz region (depending on the behavior of the intensity noise).

I did not change the value for the antispring or the actuation strengths.

J. Kissel, E. Hall

Providing some more quantitative details of Evan's calibration change:

The reference optical gain (newly installed in FM8, called "ER10gain") is now 8.40e-7 [m] / DARM_ERR [ct], changed from 1.102e-6 (installed in FM4, called "ER9 gain"), a change of 24%. This new optical gain, in physical units is 5.08 ([mA] of DCPD SUM) / ([pm] of DARM displacement), the expanded version of the Evan-loved units he simply calls "[mA/pm]."

The reference cavity pole frequency is now 342.0 [Hz], (newly installed in FM7, called "SRCD-2N") where it used to be 328.7 [Hz] (installed in FM3, dreadfully also named "SRCD-2N").

Both the optical gain and cavity pole were determined in rough fashion by taking the magnitude of the (PCALY's TX PD / DARM IN1) transfer function at the calibration line frequencies (331.9 and 1083.7 [Hz]), and solving the following system of equations for K (the optical gain) and fc (the cavity pole frequency):

( |H|_{@331.9 Hz} )^2 = K^2 / (1 + (331.9 / fc))

( |H|_{@ 1083.7 Hz} )^2 = K^2 / (1 + (1083.7 / fc))

i.e. the naive single-pole approximation. Solving such a system is a one-liner in Mathetmatica (which is what Evan did):

NSolve[{3.64^2 == (K^2 / (1 + (331.9 / fc)^2)), 1.52^2 == (K^2 / (1 + (1083.7 / fc)^2))},{K,fc}],

where 3.64 and 1.52 where the respective TX PD / DARM IN1 transfer function magnitudes at 2016-09-17 07:15 UTC, or Sep 17 2016 00:15:00 PDT). Evan chose PCALY's TX PD instead of PCALY's RX PD, simply because he wasn't aware that RX PD was the standard.

It should be mentioned that in trying to quantify from where he gathered these numbers for this aLOG comment, we grabbed the transfer function all through out the lock stretch of the above summarized night; highlighted in the screencap of the summary page. The transfer function values over the course of the lock (spot-checked every 15 minutes or so) yielded an optical gain and cavity that varied wildly, from optical gains from ~3 to 5 [mA/pm] and cavity pole frequencies from 250 to 370 [Hz]. We do not expect either physical parameter to varying that much. Thus, this method -- albiet delightfully simple and quick, we assume it has a very large uncertainty .

Also, though it was assumed that the optical spring frequency from SRC cavity detuning did not change (i.e. Evan did not change it), we're not confident that it has not changed. Regardless, for the time being, the reference optical spring frequency remains 9.81 [Hz].

In the words of Evan "I just wanted to do something quickly for the purposes of, and at the accuracy needed for, noise hunting. I knew the calibration group would do this much better within a week or two, so it wasn't worth the time to go through the whole shebang." I agree.

I've saved the template for the attached transfer function in

/ligo/home/jeffrey.kissel/Templates/H1DARM_Calibration_mA_per_pm.xml

which we can use for future quick-studies like this.

Kiwamu, Lisa We monitored the intensity noise coupling to DARM over more than 2 hours during one of the long lock tonight by injecting noise in the ISS outerloop excitation point. Labels correspond to local times (September 16). The coupling changes significantly over time. Kiwamu tried to reduce the CO2 ITMX power to see if we could maintain a low coupling, but that didn't really work. After a couple of hours we could clearly see the coupling getting significantly worse (red trace).

Tonight there was a flurry of activity with H1. There were issues with locking at the beginning of the shift, but it got better....we had a range reminiscent of H1 during S6: 19Mpc! :) Slowly but surely, we're gettin' there.

Locking Notes:

At the beginning of the shift, had issues locking ALS. This was traced down to the wrong polarizations.

FOM Note on Nuc5:

Cheryl mentioned this was booted during the day, and then it died & no DMT Viewer/DTT came up on their own. I rebooted nuc5 and conversely to last night, the DMT seismic trends looked fine & current.

I was actually loking at the "Fiber trans wrong pol (%)" numbers after a number of subsequent locking attempts and noticed a change of ≈ 4% over the course of a couple of hours. Y arm was worse than X by about 4%. Perhaps we should make this one of our weekly FAMIS checks to keep folks up-to-speed on how to deal with this? Some of us have done it numerous times and I'm willing to bet some of us have NEVER done it.

Since the lock was so stable, I could not avoid measuring the DARM open loop for calibration purpose tonight. I have tuned the excitation amplitudes of the 4-1200 Hz DARM OLTF template because some frequency points had too high excitation causing saturation on ETMY DACs. Also for completeness, I have taken a Pcal sweep as well. I will analyze the data later.

The dtt files can be found at:

/ligo/svncommon/CalSVN/aligocalibration/trunk/Runs/ER10/H1/Measurements/DARMOLGTFs/2016-09-15_H1_DARM_OLGTF_4to1200Hz.xml

/ligo/svncommon/CalSVN/aligocalibration/trunk/Runs/ER10/H1/Measurements/PCAL/2016-09-15_H1_PCAL2DARMTF_4to1200Hz.xml

I have processed the data that I took.

Since in the end the calibration filter I got was close to what Evan H. installed (29796) within several % above 100 Hz, we diecided not to re-update the calibration filters for now.

[Fitting Results]

= = = = Optical gain = 1.126242e+06 +/- 1.333590e+03 [cnts/m] Cavity pole = 3.366236e+02 +/- 1.283924e+00 [Hz] Time delay = 6.249683e+01 +/- 9.003380e-01 [usec] Spring frequency = 8.721946e+00 +/- 1.188382e-01 [Hz] Spring Inverse Q = 3.572832e-02 +/- 4.797796e-03 [Hz]

I have used Craig's optical spring function (T1600278) which uses f_s and Q to characterize the low frequency behavior of DARM. Also, the uncertainty was derived based on the covariance matrix from an mcmc sampling (28302). I have already loaded the calibration filters in CAL-CS which are in FMs 2 and 3 of DARM_ERR, but as I wrote above, we are not going to use this and keep using Evan H's filter for now until we assess the actuator functions. See the first attachement for comparison. This measurement suggests slightly worse shot noise above 100 Hz. The latest filter is 7% worse at 1kHz with repspect to the filter that are currently in. Also, for a comparison purpose, I plotted the old calibration filter from ER9 which higher than the latest two filters by about 20-30% across the entire frequency.

[Some data and scripts]

I have used Evan G's DARM code to extract the sensing function. The script is available at:

/ligo/svncommon/CalSVN/aligocalibration/trunk/Runs/PreER10/H1/Scripts/DARMOLGTFs/extractOptResp.m

The data are available at

/ligo/svncommon/CalSVN/aligocalibration/trunk/Runs/PreER10/H1/Measurements/DARMOLGTFs/2016-09-15_H1_DARM_OLGTF_A_ETMYL3LOCKIN2_B_ETMYL3LOCKIN1_tf.txt

/ligo/svncommon/CalSVN/aligocalibration/trunk/Runs/PreER10/H1/Measurements/DARMOLGTFs/2016-09-15_H1_DARM_OLGTF_A_ETMYL3LOCKIN2_B_ETMYL3LOCKIN1_coh.txt

/ligo/svncommon/CalSVN/aligocalibration/trunk/Runs/PreER10/H1/Measurements/DARMOLGTFs/2016-09-15_H1_DARM_OLGTF_A_ETMYL3LOCKIN2_B_ETMYL3LOCKEXC_tf.txt

/ligo/svncommon/CalSVN/aligocalibration/trunk/Runs/PreER10/H1/Measurements/DARMOLGTFs/2016-09-15_H1_DARM_OLGTF_A_ETMYL3LOCKIN2_B_ETMYL3LOCKIN1_coh.txt

/ligo/svncommon/CalSVN/aligocalibration/trunk/Runs/PreER10/H1/Measurements/PCAL/2016-09-15_H1_PCAL2DARMTF_4to1200Hz_A_PCALRX_B_DARMIN1_tf.txt

/ligo/svncommon/CalSVN/aligocalibration/trunk/Runs/PreER10/H1/Measurements/PCAL/2016-09-15_H1_PCAL2DARMTF_4to1200Hz_A_PCALRX_B_DARMIN1_coh.txt

The fitting code (written in python notebook) is attached.

Matt, Terra

Status of PI after TCS work and ring heater change transient (for at least the first three hours of 50 W lock):

3 hours into the lock and all PI's are stable. Leaving PI control with Matt for the night.

Another 3 hour lock and similar PI story.

These modes shift very little in frequency during a lock stretch (see attached). I've tightened up the individual band passes quite a bit (~1 Hz) to see if that helps next lock. Still need to check lock to lock variation.

Kiwamu I, Jeff K, Darkhan T,

Overview

Today we looked at the calibration line coherence values calculated in the front end. We discovered that in the front-end model with the currently used averaging parameters the coherence value is updated once every 10 seconds (first 1.5 minutes in Fig. 1).

We propose modifying the averaging code to improve coherence calculation and avoid potential aliasing (see details).

Details

A front-end model that calculates coherence uses N data points taken every Scycles computational cycles to calculate cross-spectral density of the signals. Scycles is controlled by an EPICS record $(IFO):CAL-CS_TDEP_COH_STRIDE (or simply STRIDE): Scycles = FE_RATE * STRIDE. There are drawbacks associated with this approach:

STRIDE seconds;

We can deal with the first problem listed above by reducing STRIDE. On Fig. 1 we show coherence values for N = 10 and STRIDE set to 10, 5, 1, 1/16 and again 1. Notice that this test was done when the IFO was not locked, thus we do not expect a coherence of ~1. When STRIDE is set to 1/16, we can see that the number of averages must be increased in order to include actual fluctuations in the signals (in the last 2.5 minutes N = 120).

Fig. 1

Several minutes later IFO locked (at t = -5 in Fig. 2) and the coherence became ~0.8. After we set the line amplitude to its nominal value we got coherence of ~1.

Fig. 2

Next, to avoid aliasing we should use all data points (equivalent to setting STRIDE = 1/FE_RATE in the current code) and increase N accordingly. Thus to integrate over 10 seconds and avoid aliasing the current code will require O(FE_RATE * 10) = O(160k) operations per cycle and a buffer for 160k values, which is unnecessary expensive.

A following minor modification of the averaging code can solve the issue described above. Instead of adding every Scycles'th data point into the averaging buffer, we could insert an average of Scycles values. E.g. buffer_and_average() can be modified as follows:

...

static int mini_sum = 0;

...

//Increment cycle count

mini_sum += data;

cycle_counter++;

if (cycle_counter >= cycles_between_data) {

buffer[current_pointer] = mini_sum / ((double) cycles_between_data);

current_pointer++;

cycle_counter = 0;

mini_sum = 0;

}

...

With this modification and N = 160, STRIDE = 1/16 (Scycles = 1024), the coherence will be calculated with 10 second integration and will require O(160) operations per cycle, and the coherence value will be updated every 1/16 of a second.

Jeff K, Kiwamu I, Joe B, Darkhan T,

The modifications suggested above have been implemented at LHO (the modification was implemented during a bug fix, LHO alog 29876). The modifications also include an increased max buffer size:

...

#define MAX_SIZE 256

...

static double mini_sum = 0;

...

//Increment cycle count

mini_sum += data;

cycle_counter++;

if (cycle_counter >= cycles_between_data) {

buffer[current_pointer] = mini_sum / ((double) cycles_between_data);

current_pointer++;

cycle_counter = 0;

mini_sum = 0;

}

...

The changes have been committed to cds_user_apps repository, r14301.

Following is how coherence was calculated for locked but with high noise floor at lower frequencies (see attached displacement ASD during this measurement), so only PCAL_LINE2 (at 331.9 Hz) has coherence of ~1, and all three of the ~35 Hz lines do not have good coherence:

Fig. 1

The coherences were calculated with H1:CAL-CS_TDEP_COH_STRIDE set to 1/16 and H1:CAL-CS_TDEP_COH_BUFFER_SIZE (N in the original alog) set to 80 (at [-4, -2] min time interval) and 160 (at [-2, 1] min time interval). With H1:CAL-CS_TDEP_COH_BUFFER_SIZE set to 160, each of the coherence calculations include data points from past 10 seconds.

Attached is a plot of the DARM time-dependent parameters calculated in the front-end when the IFO noise floor was reasonably low (at about 23 UTC). Notice that Y-axis for coherence is zoomed to 1 for a better detail.

It seems that the ER9 Matlab DARM model parameters for H1 that was used for calculation of current TDEP EPICS values needs an update. The ESD sign is opposite to the one in the DARM model. Calculation of κPU is hugely biased due to the wrong sign of κTST and it's magnitude being incorrect by an order of magnitude.

During last night's lock stretches the sign of κTST calculated in the front-end was positive (see attachment 2), opposite to the currently calculated value. A possible explanation for this is that L3 stage sign flip commisioning activities are underway (see LHO alog 29860).

Neither PIT or YAW trends were near/approaching +/-10urads, so it looks fine. Nothing obvious on the SUM trend either.

This CLOSES FAMIS #4693.

[Jenne, Sheila, Matt]

On our way to trying for some low noise, we went through the CoilDrivers state. But, somehow there was some buggy code in there that it was only trying to switch the UL coil of all the optics ('PRM', 'PR2', 'SRM', 'SR2', 'BS', 'ETMY', 'ETMX', 'ITMY', 'ITMX') over and over again, and never going to any other coils. After a few minutes of this, we lost lock. I don't know that I can prove that that's why we lost it, but we lost lock on this state yesterday also, and certainly having 3 coils one way, and one coil continually going between states 1 and 3 isn't helping keep us locked. Code fixed, we'll try it again next lock.

Jeff K, Darkhan T,

Overview

CAL-CS synchronized oscillator settings for cal. line coherence calculations were lost after the recent power glitch (LHO alog 29592). The settings were lost because after populating the settings (see LHO alog 28995) on August 10, not all of the channels were monitored by SDF_OVERVIEW.

Today we restored the coherence calculation settings and accepted the changes in SDF_OVERVIEW.

Details

The power glitch did not cause losses of the H1CALCS filters, so running set_coherence_h1.py (that populates filter modules) was not necessary this time (only changes names of the "1/f^2" filters to ":1,1", same as in PCAL models).

However filter module switches needed to be turned on (those previously weren't monitored by SDF_OVERIVEW). Some of the synchronized oscillator settings were also lost during the power glitch, they have been fixed now.

Today we updated coherence calculation settings for the following lines:

35.9 Hz - ESD, SUS_LINE1 36.7 Hz - PCALY_LINE1 37.3 Hz - DARM_LINE1 331.9 Hz - PCALY_LINE21083.7 Hz - PCALY_LINE3

All channels have been added to the list of monitored channels and the values have been accepted in SDF_OVERVIEW tables (safe.snap and OBSERVE.snap).

Note: IFO was not locked when the screenshots were taken.

Terra, Dave:

new h1susprocpi model was installed. This adds 64x2k chans to the science frame. The 'place holder' zeroed data were removed at the same time. DAQ was restarted.

These 64 channels we're now saving are the BP_IN1 and DAMP_OUT of each mode in the damping scheme, so essentially the pre-damping loop downconverted error signal and the post-damping loop pre-upconverted drive signal.

Jeff K, Chris Whittle

Following on aLOG 28363 (initial proposal) and 29250 (installation), we measured the open loop gain of the IMC loop (without full CARM) with the AG4395A, both with and without the daughter board 200 kHz pole. The GPIB is still connected to the AG4395A by the Common Mode Board.

TFAG4395A_15-09-2016_140247.txt has the transfer function without the daughter board, TFAG4395A_15-09-2016_140553.txt with the daughter board. The attached plots were generated with daughter_tf_plots.py.

See the attached plots of open loop gain, loop suppression and closed loop gain. Takeaways:

Also note some variation in the OLG at about 200 kHz compared to the previous measurement.

J. Kissel I've now measured the CARM Open Loop Gain Transfer Function in the two different states of the IMC PDH common mode board's new 200 kHz pole daughter board. As expected from above, the CARM loop is barely affected by the 200 kHz response change. (Also note that the daughter board can be turned on and off at will without affecting a 2W DC READOUT lock.) As such, I have left the 200 kHz pole enabled, and accepted H1:IMC-REFL_SERVO_FASTOPT as "On" in the down.snap of CS ECAT PLC2 beckhoff SDF system such that it sticks after reboots (there are no safe or OBSERVE.snaps for this SDF system). Attached are the results of the measurement. TFAG4395A_15-09-2016_191957.txt is the open loop gain with the daughter board ENABLED. TFAG4395A_15-09-2016_191352.txt is the open loop gain with the daughter board DISABLED. Summarizing the attached plots in words: the CARM loop has a UGF of 15 kHz, with a phase margin of 40 [deg] and very tolerable amount of gain peaking at about a factor of 2 at 20 kHz, all regardless of the configuration of this switchable pole in the IMC PDH common mode board.

I have spent some time trying to understand the behavior of the CARM loop in full lock.

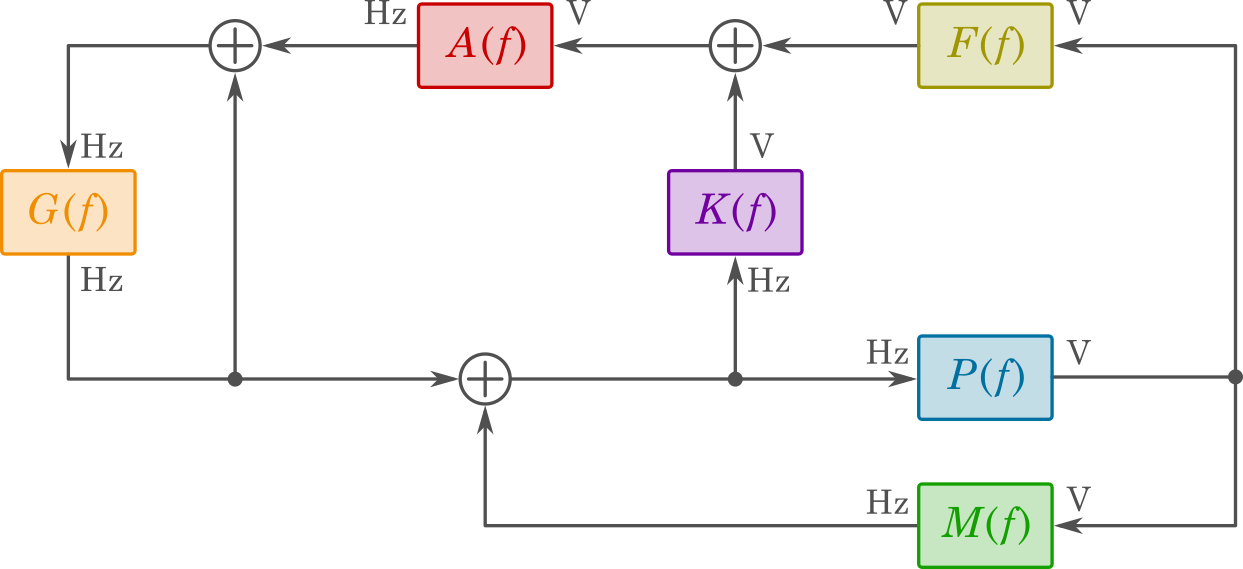

First, I have reduced the loop to the following block diagram:

P is the IFO, K is the IMC, and G is the FSS. F and M represent the fast and slow common-mode feedback paths, and A represents the IMC PDH board and the VCO. A fuller accounting of these blocks is given in the sections below.

The OLTF of CARM is then given by

where is the CLTF of the FSS. For the time being, I have ignored the slow IMC feedback (the crossover with the fast path happens below 100 Hz) and I have assumed the CLTF of the FSS is −1.

The model (described below) shows OK agreement with the measurement (taken 2015-08-14) between 1 and 40 kHz, but above that there is significant deviation in the phase.

I have also included a plot of the modeled IMC OLTF . Getting the model to agree with the measurement requires the inclusion of a mystery gain of 1/3, which I have rolled into the optical plant. Previous measurement of the IMC modulation index provided only an upper limit (which I have used here), so I am hoping that this explains some of the mystery gain.

The CARM plant is the TF taking laser frequency fluctuation to rf power on REFL9Q. It consists of the following (at 24 W):

This is multiplied by the PD TF, the SNB TF, and the CMB common TF:

Note that since this measurement we've added 7 dB to the common gain, and correspondingly removed 7 dB from the fast and slow paths. But that shouldn't matter for the OLTF estimate.

Not yet implemented. So far I have only considered the portion of the loop for which |AF| ≫ |M|.

IMC optical plant, 24 W:

PD response 880 V/W [responsivity 0.37 A/W (LHO#5277), transimpedance 476 V/A (ibid.), demod TF 5 V/V (rf volts to if volts; D0902745)]

IMC REFL input gain −3 dB [nominally 17 dB at 2.5 W PSL power]

Currently, the CLTF G/(1 − G) is assumed to be −1. I have a measurement of G from Peter K, but I have not yet included it here. Below 100 kHz, the CLTF deviates from −1 Hz/Hz by less than 50 % in magnitude and 5° in phase (see attachment).

IMC common/fast path TF:

IMC VCO TF:

Evan has told me that the above diagram and OLTF equation are wrong.

He's given me the liberty to preempt the publication of his thesis and provide the erratum for this entry.

The open loop gain transfer function of the CARM loop is defined by the attached diagram,

H = bar{G} A K P (F/K + M) / (1 - bar{G} A K)

Where again,

G = open loop gain of the FSS

bar{G} = G / (1-G) = closed loop gain TF of the FSS

A = the IMC Common Mode Board and IMC VCO

P = electro-optical CARM plant of the IFO

K = electro-optical IMC plant

F = CARM fast path through CARM Common Mode Board (fed to the input of the IMC Common Mode Board to IMC VCO)

M = CARM slow path to IMC Length control of MC2