Some more items related to POP X commissioning:

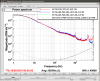

Gain and whitening

I set the analog gain at 39 dB, which is what is required to make the whitening chassis + ADC dominated by the input noise of the whitening chassis at 1 Hz. This might be overkill.

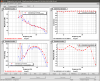

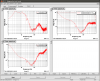

Phasing and quadrature separation

We wanted to check the quadrant phasing on POP X using a laser that can be amplitude modulated at 36 MHz. I used the same ISC laser that Kiwamu and others have used previously on other ISC photodiodes (e.g.: 9630).

Today this laser was putting out 3.4 mW dc. I drove its rf modulation input with −40 dBm at 36.4 MHz, and then tuned the frequency until the beat note showed up in the digital system at around 40 Hz. Assuming Kiwamu's calibration is still correct, this implies a total rf optical power of about 55 µW pk coming out of this laser.

The separation between I and Q for each quadrant was already pretty good (see attachment), and only needed a few degrees of adjustment.

I also wanted to balance the relative phase rotation of the four quadrants by zeroing the phase between I1 and I2, then I1 and I3, and then I1 and I4. However, by physically rotating the orientation of the laser relative to the WFS diode, I found that I could change these relative phases by tens of degrees. So it seems this setup cannot be used to set the quadrant rotations.

The beat note showed up in each quadrant with about 5000 ct pk amplitude (with a 20% spread between the quadrants). Assuming a large fraction of the laser light is falling on the diode, this allows us to estimate the order of magnitude of the gain of each quadrant: it is of order 4×106 ct/W, assuming no analog gain from the whitening chassis, no digital gains, and no whitening.