Mayank, Sheila, Jennie W, Ryan S, Elenna, Jenne, Camilla, Robert.

Follow on from 82401, mostly copied Jenne's 77968.

As soon as we started setup, the IFO unlocked from an EQ and we decided to do this with the IFO unlocked.

Ryan locked green arms in initial alignment and offloaded. Took ISC_LOCK to PR2_SPOT_MOVE (when you move PR3 it calculates and moves PR2, PRM and IM4).

Green beatnotes were low but improved when we started moving. Steps taken: Move PR3 Yaw with sliders until ALS_C_COMM_A beatnote decreased to ~-14 and then used pico A_8_X to bring it back. Repeated until PR3 M1 pitch was 1-2urad off and then Mayank brought back pitch with PR3 sliders. Repeated moving PR3 yaw sliders and picos.

Started with PR3 (Pitch,Yaw) at (-122, 96), went to (-125.9, 39.5), were aiming for Yaw at -34. But, at (-124, 68) we lost the beam on AS_AIR, whoops.

Once we realized that we fell off AS_AIR so took PR3 back to last time we had light on it (68urad in yaw slider), ignoring green arms with the plan of moving back to 38urad by moving SR2 to keep light on AS_AIR. Moved SR2 in single bounce (ITMY misaligned) to increase light on AS_AIR. We couldn’t go any further in PR3 yaw with keeping light on AS AIR so we decided to revert green picos to work with 68urad on PR3. WE took PR3 back to (-125.9, 39.5) and reversed our steps of sliders and picos.

After we got here, Ryan offloaded green arms and we tried to go to initial alignment. No flashes on init align in X arm or y-arm (touched BS for y-arm). We would usually be able to improve alignment while watching AS_AIR but the beam wasn’t clearly on AS_AIR. Improved beam on AS_AIR by moving SR2/3.

Ran SR2 align in ALIGN_IFO GRD. This seemed to make some clipping worse, are we clipping in SR2? Still working on SR2 alignment. Maybe we should update the ISC_LOCK PR2_SPOT_MOVE state to have SR2/3 follow align so that we don't loose AS_C and AS_AIR.

Regarding "Improved beam on AS_AIR by moving SR2/3."

We found that by moving SR2/3 by hand, or by engaging SR2 align and moving SR3 (SR2 follows), we can make improvements in the AS_C NSUM and the AS_C yaw position, but that clearly does not fix all the problems with input align and the terrible beam shape we saw on the AS AIR camera. This leads us to believe that part of the problem is upstream, as in even if we fix everything at the output, we may have caused some other clipping problem in the PRC.

Sheila and I tried adjusting the pointing of PR2 to see if we could improve the input align issues, but that seemed to have very little effect.

I think that a possible reason why our PR2 spot moves have gone poorly is because the PR2 spot move function in the guardian does not have the correct constants to ensure the spot moves on PR2 and not on the other optics.

Looking back in time, the PR2 spot move function was first written by Stefan in 2016 (as I can find, see: 28420, 28442). Looking at his code and the current guardian code which was originally copied from his code, the adjustment values are exactly the same:

pitPR3toPR2=-9.2;

yawPR3toPR2=+9.2;

pitPR3toIM4=56;

yawPR3toIM4=11;

pitPR3toPRM=1.5;

yawPR3toPRM=2.2;

These differ from the values you would calculate from the ray transfer matrix, which Stefan notes in a comment in 28442. My guess is that the difference in those values is related to whatever calibration we add into the optics sliders.

Also, Jeff updated the IM slider calibrations to microradians last April, see: 77211. I can't find any alog (so far) that reports an update to the PR2 spot move values in the guardian to account for this recalibration.

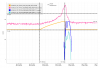

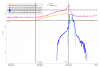

Sheila pointed me to the May 20, 2024 spot move where she says she updated the adjustment values from the guardian: 77949. However, the values she uses in this alog are not reported, and it doesn't look like the guardian numbers actually changed. I looked at the saved ndscope from that time and eyeballed the values to be approximately:

yawPR3toIM4 = 0.875

yawPR3toPR2 = 10

yawPR3toPRM = 2

You can check the attached screenshot to see how I calculated these values. These numbers are clearly different compared to the numbers above, so I don't really know what happened here. But, it seems that if we want to do a PR2 spot move again, we should check to make sure we are adjusting the optics appropriately.

You can also find the template for this scope in "/ligo/home/sheila.dwyer/ndscope/PR2_spot_move_jennie.yaml" if you want to check yourself.