Summary: I fit the peaks in OMC mode scan data that was taken with the full IFO locked, plots attached. Using the carrier peak heights we can estimate the contrast defect; the result for this data is ~150ppm. It's hard to tell if the sidebands are imbalanced, but the +/-9MHz sidebands don't agree very well in the higher order modes.

Details: Before we handed off to DC readout on Tuesday, I collected a few quick scans of the OMC to measure the sideband & higher-order-mode content at the dark port. The analysis of this data follows Koji's work for a similar measurement for L1.

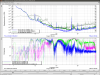

The settings for the scans were a 50-second ramp in PZT2_EXC, 100V amplitude with a starting voltage of zero (i.e., sweeping the entire range of the PZT). All of the switchable whitening stages for the DCPDs were turned off. The data were collected with DTT, 256Hz bandwidth (sampling rate about 512Hz). Text files of the data are here: DARM offset on, DARM offset off. The alignment of the IFO was a little shaky so there is some variation in peak height, but overall the peak structure is very similar from one scan to the next, and the data quality is good enough to resolve peaks out to eighth-order modes.

The mode identification was made based on the expected mode frequency from the known OMC FSR (261.72 MHz) and HOM spacing (57.33 MHz [1]), using a polynomial fit to the voltage of the peaks. The fit was initialized with one slope parameter using the four TEM00 peaks of the 45MHz sidebands, and refined to a 3rd-order polynomial using the carrier peaks TEM0-9 (these peaks were well-separated from other features in the scan and were easily distinguished using a linear voltage-to-frequency function). The HOMs for the sidebands (both 45MHz and 9MHz) were then identified using this 3rd-order polynomial. All the identifiable peaks were ultimately fit using 3-parameter lorentzian functions (after subtracting away the contribution from larger, nearby peaks) to precisely fix the peak height and position.

The first two plots attached show the expected mode location of the sideband and carrier modes out to high order. Not all of these modes have a matching peak; the choice of which peaks to fit was made using this plot, based on their separation from other peaks and how accurately the peak location matched the prediction. For example the HOMs of the +45MHz (USB) sideband are degenerate with the -45MHz sideband above order 2, and were ignored. Also the -45MHz (LSB) sideband modes above 4th order do not fall on a recognizable peak. The +/-9MHz sidebands (usb and lsb) are distinguishable out to eighth order, although lsb0 is degenerate with CR9, and the lsb1 is degenerate with USB0.

The second two plots show the peaks that were retained for the lorentzian fits; their heights are given in the tables below. The sum of the fit of the peaks is shown by the orange line.

The final two plots compare the reconstructed peak location, using the 3rd-order polynomial calibration of voltage to frequency, to the expected frequency. In general the agreement is very good, although in the data with the DARM offset off, the 2nd order lsb (-9MHz) mode is about 1MHz away from where it should be (about 0.14 volts).

Some modes are fit twice (separated by 1 FSR), I have included both peak heights in the table, and averaged them in the sum. This gives a sense of the accuracy of any one measured peak height - for the smaller modes or modes sensitive to alignment, the variation from one sweep to the next can be tens of percent. (Sometimes these variations from one FSR to the next are consistent across different sweeps, sometimes not.) We might try this again when the IFO is more stable.

Carrier Peaks (CRn)

|

|

Height (mA) |

|

|

Order |

DARM offset off |

DARM offset on |

|

0 |

0.029, 0.058 |

16.323, 15.556 |

|

1 |

0.231 |

0.123 |

|

2 |

0.327 |

0.638 |

|

3 |

0.501 |

0.647 |

|

4 |

0.264, 0.229 |

0.071, 0.052 |

|

5 |

0.443, 0.429 |

0.473, 0.436 |

|

6 |

0.211 |

0.134 |

|

7 |

0.185 |

0.145 |

|

8 |

0.178 |

0.146 |

|

9 |

0.443, 0.427 |

0.215, 0.332 |

|

|

|

|

|

Sum |

2.80 |

18.55 |

-45MHz sideband (LSBn)

|

|

Height (mA) |

|

|

Order |

DARM offset off |

DARM offset on |

|

0 |

19.291, 18.628 |

19.442, 19.312 |

|

1 |

0.711, 0.540 |

0.531, 0.619 |

|

2 |

1.31 |

1.093 |

|

3 |

0.123 |

0.055 |

|

4 |

0.044 |

0.052 |

|

|

|

|

|

Sum |

21.06 |

21.16 |

+45MHz sideband (USBn)

|

|

Height (mA) |

|

|

Order |

DARM offset off |

DARM offset on |

|

0 |

19.750, 19.185 |

19.920, 19.687 |

|

1 |

1.421 |

0.221 |

|

2 |

0.794 |

0.768 |

|

|

|

|

|

Sum |

21.69 |

20.80 |

-9MHz sideband (lsbn)

|

|

Height (mA) |

|

|

Order |

DARM offset off |

DARM offset on |

|

0 |

degenerate with CR9 |

degenerate with CR9 |

|

1 |

degenerate with USB0 |

degenerate with USB0 |

|

2 |

0.201 |

0.284 |

|

3 |

0.180 |

0.472 |

|

4 |

0.610, 0.654 |

0.574, 0.672 |

|

5 |

0.066, 0.079 |

0.127, 0.123 |

|

6 |

0.150 |

0.291 |

|

7 |

0.033 |

0.038 |

|

8 |

0.077 |

0.113 |

|

|

|

|

|

Sum |

1.34 |

1.66 |

+9MHz sideband (usbn)

|

|

Height (mA) |

|

|

Order |

DARM offset off |

DARM offset on |

|

0 |

0.043, 0.040 |

0.045, 0.049 |

|

1 |

0.294 |

0.131 |

|

2 |

0.116 |

0.110 |

|

3 |

0.087 |

0.065 |

|

4 |

0.128, 0.118 |

0.161, 0.142 |

|

5 |

0.052, 0.057 |

0.086, 0.084 |

|

6 |

0.013 |

0.022 |

|

7 |

0.025 |

0.017 |

|

8 |

0.021 |

0.014 |

|

|

|

|

|

Sum |

0.78 |

0.64 |

Note that the HOM content of the -9MHz sideband is 3x larger than the +9MHz sideband. Not sure if this tells us something about the sideband imbalance.

Contrast Defect

Using this data we can calculate the contrast defect in a couple of ways.

First, following Valera's method from the L1 measurement (with some advice from Koji), we assume the higher-order carrier modes (with a DARM offset ON) are due to the contrast defect, minus some misalignment and mode-matching into the OMC. The alignment for this measurement was good (the power in the carrier TEM00 mode did not change after the OMC was locked and the dither alignment turned on), so I won't correct for misalignment. Correcting for OM1/OM3 transmission (0.95/0.99), we calculate the contrast defect as the ratio of the carrier TEMnm modes to the carrier power incident on the BS that transmits through the SRM:

Sum of carrier TEM(nm > 00) with DARM offset = 2.62mA.

Carrier power available at the dark port is a function of input power, IO efficiency, recycling gain, and SRM transmission --> Pin * E_IO * Gprc * Tsrm = 2.8W * 0.88 * 33 * 0.37 = 30.1W

Correction for OM1/OM3 transmission, and DCPD responsivity --> 2.61mA / (0.95 * 0.99 * 0.75A/W) = 4.62mW of carrier light into HAM6

CD = 4.62mW / 30.1W = 153ppm

Some of this HOM content is from the TEM00 mode that is not mode-matched into the cavity, so this is an overestimate. The mode-matching from a single bounce into the OMC is ~0.9, so the overestimate may be at the 10% level.

Another approach uses the data without a DARM offset, and assumes all the carrier light at the AS port in this state (2.80mA) is due to the contrast defect. Here we get:

CD = 2.80mA / (0.95 * 0.99 * 0.75A/W * 2.8W * 0.88 * 33 * 0.37) = 132ppm

The uncertainty of these results is likely tens of percent, due to the assumption of the recycling gain and the variability of the carrier peak heights. I haven't accounted for the input power lost to the sideband generation, this will increase the contrast defect by a few percent.

[1] This value for the higher-order mode spacing is slightly different than what Koji measured on the bench (~57.45MHz). In my initial fits to the carrier modes there was a small discrepancy between HOM frequency and position (~10s of kHz), which grew with mode number. The peak identification for the carrier modes is unambiguous (since they are so well-separated from each other and the sideband modes), so I tweaked the HOM spacing until the discrepancy was gone. Essentially I have used the HOM spacing as an additional fit parameter - since we have >10 data points and five fit parameters (4 polynomial terms + HOM spacing) this seemed like an acceptable choice. The change in mode frequency is at the 2% level for a 9th order mode.