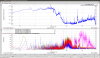

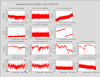

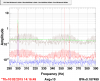

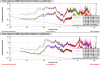

Attached is spectra from WHAM6 looking at the GS-13 INF IN1s--before the digital filters.

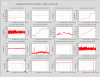

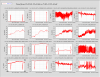

The Red traces where taken at 1417utc (~6am local) with the FM4 & FM5 ON, my understanding and based on the plots here, this is analog low gain and whitening.

The Blue traces are from 1550utc with FM4 ON and FM5 OFF--analog low gain but not whitened.

Green traces are from 1650utc with both FM4 & 5 OFF--analog high gain and not whitened; The brown traces start at 1722utc with FM4 OFF and FM5 ON, that is, analog whitening and high gain.

Again, based on the plots, the switches appear to be doing what I thought and expect.

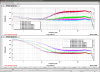

Do we have saturations when in whitened high gain? No, based on the H1:FEC-51_ACCUM_OVERFLOW, no saturations accumulated during any of the measurements.

What about being ADC limited in low gain without whitening. Included on the traces are the ADC noise from the svn. It certainly looks like in low gain without analog whitening, we approach the ADC limit at 100Hz and very likely about a few 100Hz.

Conclusion--Leave FM5 ON all the time--we are not saturating in high gain and we are near the ADC noise in low gain without whitening...but wait:

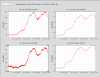

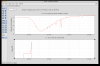

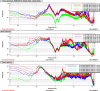

But what about those ugly lumps between 200 and 400Hz? They do not show up on the unwhitened hi gain signal but are evident on the other three configurations. The ringing is exactly 1Hz and the beating is about 45Hz. Maybe this suggests a problem with the whitening filter? Maybe we should not whiten the signal when in high gain.

I added a zoom in of the high frequency beat stuff.

From JeffK's 16425, while I'm a bit confused as to Jeff's language I think i understand:

These two states are compensated for digitally in FMs 4 and 5 of the GS13INF banks, by the difference between the two states (the overall gain of 2 is folded into the calibration filter). FM4 is the switchable gain compensation, FM5 is the switchable compensating de-whitening filter. The front-end code for the HAMs and BSCs is set up that these digital banks control the analog switching.

- When FM4 is ON, the gain switch is HI (or a binary output of 1), so the analog gain is 2, and FM4 compensates the gain of 10 difference.

- When FM4 is OFF, the gain switch is LO (or a binary output of 0), so the analog gain is 20.

- When FM5 is ON, the analog whitening is LO (or a binary output of 0), so there is no whitening, and FM5 compensates the z:p = 50:10 difference.

- When FM5 is OFF, the analog whitening is HI (or a binary output of 1), so the whitening is engaged.

and I think the FM5 states are backwards as to the above verbeage. The digital DWH filter certainly looks like a De-Whitening and the above traces bare out the FM5 enables the analog whitening.

dtt template is in /ligo/svncommon/SeiSVN/seismic/HAM-ISI/H1/HAM6/HAM6_GS13_GAIN_DWH.xml