Kiwamu, Sheila, Evan, Lisa, Daniel, Elli, Dave O., Dan, Alexa

On December 3rd 2014, 3:01 UTC we had the IR resonanting in all the cavities. MICH, PRCL, and SRCL were still on the 3f signals; DARM was on AS 45Q and CARM was on REFL 9 I at 0 pm. This is what we did:

- We started with CARM controlled by sqrt(TRX+TRY) and DARM by AS 45 Q.

- With the CARM offset at -15, we measured the UGFs of the DRMI loops: PRCL ~80 Hz, MICH ~ 10 Hz, and SRCL ~ 20 Hz (this was with the reduced gain as Lisa noted in the last alog)

- We then compared the TFs between the normalized REFL9 I signal and the sqrt(TRX+TRY) signal. With a gain of -40, the TF was relatively flat (see TRvsREFL_CARM.pdf)

- We also measured the CARM UGF with the CARM offset at -15 and found that the UGF was ~90 Hz with zero phase margin. We turned up the REFLBIAS gain from 0.8 to 1.5; this brought the UGF to 150 Hz with 25 degree phase margin. We also measured DARM at this point and found the UGF of 16 Hz, with a phase margin of 40 deg.

- With a CARM offset of -15.5 we set the normalized REFL 9I offset such that the output was zero, and then adjusted the input matrix to tranistion from sqrt(TRX+TRY) to the normalied REFL 9I into the REFLBIAS input. Finally, we zeroed the offset. We stayed locked for about 12 min. We repeated this and Evan adjusted the offset around to ensure that we were actually at a maximum power build up in the arm.

- As we locked, REFL LF power went from 75mW to 33mW, and TR QPD sum went from 4 to 143 counts. Meanwhile, ASAIR LF stayed constant. We are missing build up in the arm, and the next step will be to investigate this.

- With CARM on REFL was also took several more transfer functions. The CARM TF looked flat around the UGF. We need to improve this loop. Evan will make an attachement with these pdfs. We also need to transition REFL 9I to the analog signal in the summing node board.

- This is all in the guardian now.

- I have attached a picture for good measure.

Here are the REFL and arm powers for a few values of the CARM offset (controlled via TR_REFL9, the digitized REFL9I error signal). These were taken with tdsavg and a 5 s average.

It appears that we are indeed sitting at a minimum of REFL LF and a maximum for the arm transmissions.

| TR_REFL9 offset (ct) | TRX QPD sum (ct) | TRY QPD sum (ct) | REFL LF (ct) |

|---|---|---|---|

| −1.5 | 78 | 87 | 53 |

| −1.0 | 100 | 112 | 45 |

| −0.5 | 118 | 134 | 39 |

| 0 | 129 | 146 | 36 |

| +0.5 | 129 | 146 | 36 |

| +1.0 | 119 | 134 | 39 |

| +1.5 | 101 | 115 | 45 |

| +2 | 80 | 90 | 51 |

| +2.5 | 56 | 63 | 60 |

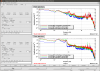

This is a trend of relevant signals during the locking sequence. We are running ASC loops with low bandwidth on BS, PRM and DHARD. The transition to REFL_9I happens at time = 600 sec. The relative increase in the power build up is only 15%. Dan will post more precise numbers, but his first estimate is that we have a total of 280 mW at the AS port, 75% due to sideband power, 25% carrier. POP_DC only increases by a factor of 3 when the carrier is resonant..it should be more like 10-20.

Congratulations! Way to go. Now let's chase that buildup..

Excellent!

Here are the OLTFs taken at 0 pm CARM offset. The CARM loop has turned out kind of weird as it crosses unity, but it seems the phase bubble can support it. We might need to do some retuning.

We rung up the BS roll mode at 25.7 Hz

And we beheld, once again, the stars.

Here are some power calculations for the AS port and the TMS IR QPDs:

==== AS_C sum output (the channel that is used for the shutter logic) ====

quantum efficiency = 0.8, QPD transimpedance = 1000 ohms, sum output gets a factor of 1/4 from R23 (see D1001974) --> 200 volts / watt on the QPD

OM1 transmission = 5%, M6 is 50/50 splitter (see T1200410)--> AS_C gets 2.5% of the light entering HAM6

AS_C sum output is 1.4V when locked at zero CARM offset: 1.4 V * (1/200) * (1/0.025) = 0.280 W into HAM6

==== Transmitted power through the arms ====

Using the IR QPDs on the transmission monitor tables, H1:ASC-X_TR_A_SUM_OUTPUT and similar, and assuming the same QPD transimpedance electronics. (I am not sure of the calibration of the other PDs, like LSC-Y_TR_A_LF.)

These four channels currently have one stage of analog whitening and 18dB of gain --> 7.9x analog gain

Quantum efficiency = 0.8, QPD transimpedance = 1000 ohms, 2x from differential output, 32768 counts per 20V --> 2621440 counts per watt

On the TMS (see T0900385), M4 is 100% reflector for IR (assumed), M12 transmission is 5%, each QPD gets half of this signal --> TR QPDs get 2.5% of light leaving arm

The QPD signals were about 6000 counts (see attached). 6000 counts * (1/2621440) * (1/0.025) * (1/7.9) = 11.5mW leaving the ETMs

From the galaxy optics page the H1 ETMs have 3.6ppm transmission, this implies about 3.2kW in the arms.

The first figure attached is a striptool of the second lock of the evening; the second figure has trends of the TMS QPDs.

That's great, congratulations. LLO had high arm losses (maybe not this high) at one point from poorly centered beams on the test masses; that would be something to check if you haven't already.

Wonderful to see! and well-earned. Congratulations!

Great job, congratulations!