After spending far too long scratching my head about calibrating the OMC DCPD signals, I've measured the RIN of the OMC transmitted beam, and it's not pretty.

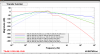

To make the measurement I locked the OMC on the side of a carrier TEM00 fringe, as described here. I measured the open-loop transfer function; this is the first plot attached (UGF is 100Hz, which is about the same as when we're dither-locked on the peak of the fringe with much higher gain in the LSC servo). To calibrate OMC-DCPD_NORM into true RIN I divided by 1/(1+G) in DTT so that the loop suppression is accounted for. To calculate the RIN seen by other PDs, I divide by the PD sum at DC.

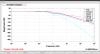

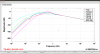

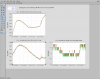

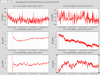

The results, in the second plot, show that the beam incident on HAM6 has some issues. At high-ish frequencies, 100Hz and up, the OMC Trans intensity noise is due to noise out of the mode cleaner. It's coherent with IM4 Trans and the ISS second loop PDs. Probably this noise can be mitigated using the ISS second loop and also reducing the IMC angular fluctuations that were described by Gabriele.

At low frequencies, between about 0.2 and 3Hz, there is huge intensity noise on the input beam to HAM6 beam that is not seen just after the IMC (neither IMC_TRANS or the ISS second loop PDs). The noise is seen in HAM6 by the OMC QPDs (in green - limited by electronics noise above 50Hz?) and by ASC-AS_C (dashed black). At high frequencies the intensity noise in HAM6 is coherent with the noise out of the IMC, but the loud stuff around 1Hz is likely due to the clipping that Keita measured yesterday.

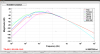

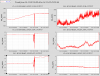

The third plot shows an attempt at characterizing the length noise of the OMC; the loop-corrected RIN was converted into meters using the derivative of the usual Fabry-Perot transmission formula at half-resonance (the conversion factor is 3.7e8 RIN/meter). This is a first step towards building an OMC noise budget, following the work by Zach at LLO. At high frequency (around a kHz), the noise begins to drop below the limit of 3x10^-16 meters/rt[Hz] prescribed by Valera's estimate in G1100903, but there's a forest of lines around 1kHz that's not unlike what was observed at L1. At lower frequencies, the noise seen at the DCPDs is dominated by the input intensity fluctuations, and it's not possible to measure the length noise that's intrinsic to the cavity. The photocurrent during these measurements was about 3mA for each DCPD (shot noise RIN of 10^-8/rt[Hz]).