Attached are 30 day trends of the ITM and ETM Vertical, Pitch, Yaw, and VEA temperature drifts. Yep, they drift.

Attached are 30 day trends of the ITM and ETM Vertical, Pitch, Yaw, and VEA temperature drifts. Yep, they drift.

These are the results of the ETMX excitations to test for working channels. Again, 4hz/10cts/pitch

re 15205,

Attached are trends from the last 20 hours. There is the ALS REFL CTRL OUTPUT(um I believe) which Nic's servo is attempting to keep zero, next is the HEPI Longitudinal Location (nm,) the servo is on when this is changing unless HEPI has tripped and is reacquiring (which did not happen.) Third plot is the Horizontal pringle of HEPI(not sure of units) giving some indication of platform(or maybe just actuator) distortion required to move in one dof while keeping the others where they started. Last is the OpLev Yaw, the HEPI RZ will not be informative as that loop is closed and will appear to be perfect. The OpLev Yaws appear to move some but I don't think more than when the servo is not on. You can certainly see the tidal effect on the REFL CTRL when the servo is not operating.

Scheduled today: ISS beam work CDS end Y PEM work U.S. Linen on site Warehouse construction work continues

no restarts reported.

conlog reporting of frequently changing channels attached

Bubba and I have stabilized the LVEA and VEA temperatures.

We still have known mechanical issues which are probably impacting the control loops so we should be able to improve things - especially XEND.

The one degree spike at XEND on the 19th was due to my attempt to outsmart the system.

Motorized variac heater controls are being ordered for the two end stations which should allow for better control and transient behavior.

We may be asking to raise the set point at XEND - so if anyone has thoughts on this please let us know.

On the evening of the 19th commissioners noticed large angular drifts on ETMX, see alog 15193. The attached plot shows temperature in end X over the past 3 days as well as the optical lever readouts. There is a clear correlation between temperature and optical lever readouts. The trace of the 0.8 C excursion on the 19th in the optical levers is obfuscated by several re-alignments of ETMX. One might wonder, if the optical lever temperature fluctuations correspond to actual optical alignment changes, or if they are just an optical lever feature. Since large alignment drifts were reported on the 19th, one might suspect the former.

Alignment changes of the order 0.5–1 µrad will require a re-alignment of the arm cavity.

Looking at a trend from 3 weeks ago shows that the temperature is now oscillating with a ~2.25 h period and an amplitude of ~0.15ºC.

Here is an LLO alog describing a measurement of the angular misalignment when their HVAC system was shut off. One can deduced a temperature dependency around 35 µrad/°C in pitch, see alog 13817. Yaw seems relatively stable. With a requirement of 0.5–1 µrad the temperature stability would need to be around 0.02ºC.

The other thing noteworthy is that it takes less than an hour for the vertical position to turn around after the HVAC system was engaged. This would indicate that the dominant thermal coupling is radiative through the chamber walls, and not conductively through the ISI. The reaction time of the ISI is of order 36 hours—which could be responsible for the long tail seen in restoring the position.

The calculation made by Brett in the above referenced link, as well as the measurements of pitch vs temperature that are reported by Stuart A in the LLO log, correspond to the pitch of the TOP mass of the quad suspension. According to the suspension model, the test mass pitch is 25% of the TOP mass pitch. So, the 30-40 urad/C for the TOP mass translates to 8-10 urad/C for the test mass. So 1 urad corresponds to 0.1 C. Still quite sensitive, but not so bad.

Not sure, if this still agrees with the observed optics drift. If I interpret the plot in alog 13639 correctly, the HVAC system was off for about 20 h, in which the temperature was rising by ~3.2 F. Assuming a linear trend we get 90 mK/h, or 15 mK in 10 minutes. The optics was drifting 0.5 µrad in 10 minutes. So, we get ~34 µrad/K at the optics.

On the other hand, looking at the temperature oscillations in EX we would expect to see 10 µrad-pp, but only see 1 µrad-pp. A time constant of ~1 hour would correspond to a pole frequency around 50 µHz which is abount 2.5 times slower than the observed oscillation. Assuming this leads to an attenuation of 8 dB, a reduction of 25% through the suspension chain would explain what we see in the optical lever.

Kiwamu, Stefan, Nic, Evan

First, some troubleshooting:

After troubleshooting, we were able to get to DRMI3f+arms with a reasonable duty cycle, so we moved on to the problem of the CARM handoff.

Instead of pursuing sqrt(TRX+TRY), we looked at REFL9I. Surprisingly, we found no response in this signal in response to different CARM offsets. We thought this might be due to bad IR alignment into the arms, so we unlocked everything, then locked the Y arm in IR, and adjusted ETMY to maximize the transmitted IR power. This improved the buildup in Y by a factor of 3, but REFL9I continued to be nonresponsive. While locked, we tried some further tweaking of the ETM alignments, with no success. Relevant UTC times: 2014-11-21, from 09:00:00 to 09:30:00.

(Stefan Evan Kiwamu Nic)

We found the ETMX suspension was changed back to distributed control on Tuesday Nov 18, 2014 at 19:14. There was no elog documenting this. We expect this was an error (or maybe a BURT restore?). It's very surprising that we were still able to do ALS control at all in the interim.

The ETMs had been distributed for a long while, but were changed to offloaded while diagnosing ALS DIFF issues.

We've now changed it back to offloaded.

I just tripped ETMX ISI (and suspension watchdogs) by sending a too large signal to M0.

(Sheila Hugh Jim Nic)

Last night we had been having some locklosses due to the VCOs which keep the green locked to the arms running out of range. Today we decided to implement a servo which slowly feeds the VCO control signals to the HEPI postition at the end station.

This was done using a simple epics based servo. (It’s similar to ezcaservo but is designed for the guardian infrastructure.)

We take the VCO control signal from (for example in the X arm) H1:ALS-X_REFL_CTRL_OUT16 and write the integrated control to H1:HPI-ETMY_ISCINF_LONG_OFFSET.

Both ALS_{X,Y}ARM guardians have a new state named LOCKED_W_HEPI_SLOW and the code looks like this:

class LOCKED_W_HEPI_SLOW(GuardState):

@fault_checker_gen(arm)

def main(self):

offset_ramp_time = 2;

servo_gain = 10;

offset_prefix = 'HPI-ETM'+arm+'_ISCINF_LONG'

ezca.write(offset_prefix+'_TRAMP',offset_ramp_time)

# arms have opposite gain

if arm=='X':

servo_gain = -1*servo_gain

self.hepi_servo = cdu.Servo(ezca,offset_prefix+'_OFFSET',readback='ALS-'+arm+'_REFL_CTRL_OUTPUT',gain=servo_gain)

@fault_checker_gen(arm)

def run(self):

self.hepi_servo.step();

return True

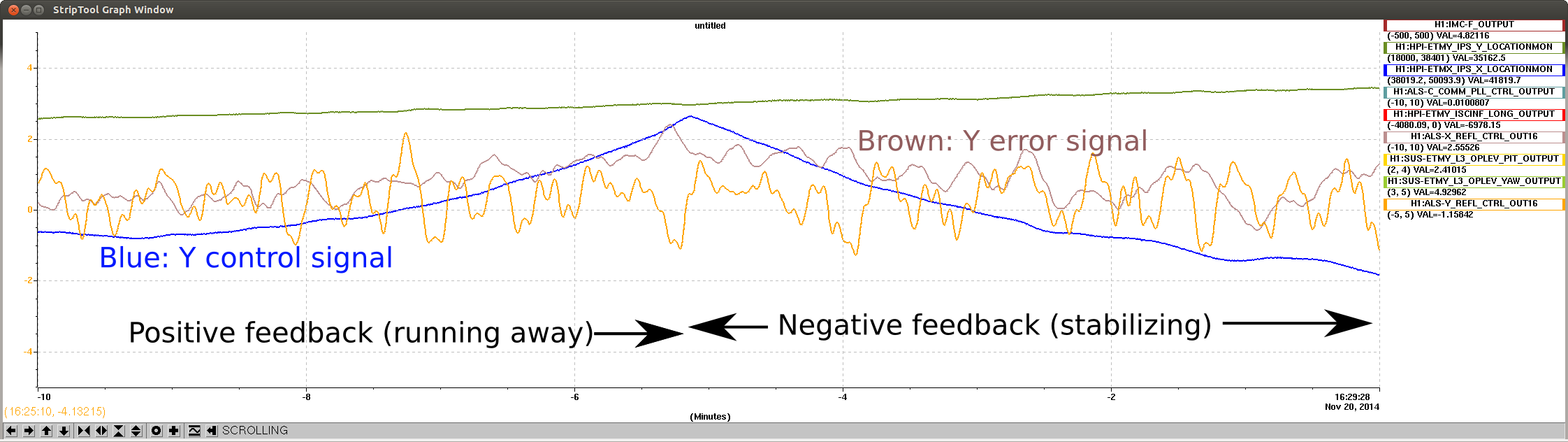

Attached is a screenshot of the servo in action. The first part of the time series has the gain with the wrong (positive feedback) sign for the Y arm servo, then it’s flipped half way through and goes back to the set point. The X arm servo is turned on with normal gain throughout.

[Sudarshan, Gabriele]

We tried to better dump the beams on IOT2R with a piece of black glass (and dumping the glass reflections with the razor blades).

The PRM was aligned, but to avoid disturbing too much the locking activities, we left the two arms and the BS aligned as well. The PRC flashes made very difficult to get any conclusive result. We think that the 18 Hz bump was not there anymore, but at the end we were not completely sure, since there was too much more noise due to the flashes. We'll try again tomorrow morning, with only PRM aligned.

For the moment we put back the upper mirror and dumped the beams with two razor blade dumps just before the two bottom mirrors. The situation is back as before.

In the meanwhile, we noticed that the periscope was not propely clamped to the table, and we accidentaly moved it. This shouldn't be important. Now we clamped it securely.

Nic ran Jim's script.

Earlier tonight, we had a large drift in ETMX pitch (1 urad over about 7 minutes). I turned off the sensor correction (ETMX ISI X only) for the last several hours, this seemed to help. Now I've turned it back on so we can see if this continues to happen overnight.

We are leaving the arms locked in green, and the mode cleaner locked. This should give a chance to see if the mode cleaner is really stable when there is no actuation on it.

Thanks Sheila, for reporting this.

I looked for minutes long features into the ISI CPS, at 0am and 4am, but did not find anything obvious over such low frequencies. However, I don't understand why the vertical Stage 1 CPS signal is so low. The local CPS signals should be quite larger if the platform was well isolated. I am getting inertial sensors and optical levers data to look into more details.

[Rich, Fabrice]

At 0am, the time series show a large drift in ETMX SUS top mass, not only in pitch but also in longidudinal, see first plot (the ylabel should say "nm"). According to the Stage 1 T240s (second plot), the ETMX ISI was performing as well as the other units, but this doesn't tell us anything about slow drift, so we need to get back to CPS data (maybe look at the rotations in the cartesian basis for the non-corrected CPS signals).

At 4am, ETMX SUS drift has stopped (third plot), though the sensor correction seems to be on (fourth plot).

K. Venkateswara

One thing to note is that turning sensor correction on is somewhat equivalent to blending at still lower frequencies than the normal 45 mHz. This makes it very sensitive to ambient ground tilt (caused by human activity or wind). It should not be used if there are people/activity near the ground seismometer.

Using tilt-subtraction makes sensor correction less susceptible to wind-induced tilt but unfortunately BRS is very sensitive to gravity gradients from people. So walking near the BRS when it is being used can cause very large low frequency signals to show up in the super-sensor.

Should we ask the operators to turn off the sensor correction at End X if they know someone is headed down there?

Did you and Evan go there around 6 PM? The attached plot shows a spike at ~6:20 PM

In general, yes, it would be better to turn off sensor correction along the horizontal directions during the day if there is a chance of someone being close to the ground seismometers.

Yes Sensor correction should not be on if there is any activity in the VEA.

Sensor correction is a form of feed forward so it assumes that the chamber and ground sensor are seeing the same thing. So someone walking by the ground sensor, making a large local disturbance can produce large motions in the platform

[Rich, Seb, Fabrice]

We are now looking into HEPI to see if it caused the drifts that was observed on the ETMX suspension. Sebastien is processing the data.

Please let us know if this is not anymore of interest because the cause of problem is now known (for instance related to John's comment on temmperature, or Nic's comment on suspension control).

A 1ºC temperature excursion was reported in alog 15212.

Sheila, Alexa, Dan, Nic, Evan

EX/EY:

Setting up sqrt(TRX+TRY):

Attempt at sqrt(TRX+TRY):

Guardian improvements:

There has been some concern that there might be excess cps noise in some of the channels. So i looked at 20 minutes of data at 1am sunday night/monday morning.

Looking only above 30Hz where the sensors have hit the noise floor, all of the coarse channels are similar and between 3.5-4.5E-10m/rrtHz about what we expect.

The stage 2 channels show two outliers, ITMX H2 and ITMX V1, maybe BS H2 also but that is close enough so that it could just be at a large offset (we expect the noise floor to go as the gap squared) I'll check that.

The first thing to do is for me to look at another time, and to check the cables and connections for those sensors

I looked at a second data set calling it "B" (24 hours later) ST2 ITMX H2 and ST2 ITMX V1 still show excess noise BS H2 is down to 4.5-5E-10m/rtHz which is a little bit noisy, but probably within what we are calling acceptable. I attached the data because Jeff asked to see the ADC noise on the plot

When I say large offset I mean > 10000 counts, so 1200 counts is centered for this discussion

ITMX Stage2 H2 & V1 CPS offsets are 900 & 3800 counts. While V1 is actually the largest offset of all the BSC CPSs, H2 is 21st of 30 (towards the bottom) of Stage2 CPS offsets. At 1200cts, BSC2 H2 ranks 17th of 30. So the offset maybe an issue for ITMX V1 but the others...? And, what about ITMY V1 at 3700 counts and ITMX V3 at 3200?

Attached are all the BSC medms showing the offsets.

Some additional info regarding the CPS - On the figures are plotted time series, integrated RMS, and ASD down to low frequencies. Somme comments:

- At high frequencies, not much to add on sensor noise (ITMX and BS both have two CPS untis with elvevated sensor noise on Stage 2). I looked at data of the Nov 17th, 18th and 19th, and get similar results.

- All Stage 1 CPS units are within 1um p2p, except BS horizontal that is moving 4 times more. Something to look into.

- At the microseism, the three vertical sensors are moving in sync, on all stages of all platforms. Probably normal (the platform is inertially decoupled down to the micro-seism with th 90 mHz blends)

- The low frequency motion amplification is about 100 times larger in the vertical directions than it is in the horizontal directions.

The 5 figures in the previous log are for data ten on the 17th at 3pm PT.

Results and comments are similar for the 18th and 19th, except for ETMX (attached plot) that shows different behavior at low frequencies, as expected with the sensor correction that was turned on Tuesday. It also shows features on Stage 2 at the SUS resonances, that might need to be doubled checks.

Could this be related to the trips on ITMX? (alog 15021)

this log seems to have gotten hijacked

I check the HAM-CPS and they all seem to be good at high frequency

Alexa, Dan, Nic, Sheila, Evan

Tonight we made some improvements to our automation, and we reduced the CARM offset with DRMI locked on 3F.

I have attached DRMI spectra on 1f and 3f with the arms off resonance (1kHz green COMM offset). The first plot is the DRMI 1f configuration; Kiwamu pointed out that one can see the periscope resonances that are present in ALS COMM noise appear in the DRMI signals. The second attachment is of the DRMI 3f configuration, and these noise features are less prominent.

Relevant UTC times:

Great progress! About the ASC, L1 uses REFL_B_45Q -> SRM with bandwidth of 100 mHz ( LLO 13513 ) in the first part of the locking sequence, as AS_RF36_I for SRM didn't work well ( LL0 13358 ). Here I see that you are using AS_RF36_I for SRM ASC in DRMI without arms...just checking.

Thanks for the information Lisa.

Also, for the record, here are several times that we lost the arm locks last night without a known reason (at least, we didn't think we were doing anything stupid at the time that would have caused the lock loss). All times are UTC, Nov 19, and the lock loss should be several seconds before the time I wrote down.

2:36:27, 3:06:34, 5:58:43, 6:12, 6:25:08, 6:51:07, 7:40:50

Here is the sensing matrix of DRMI3f with 7 nm (= 1000 Hzgreen) CARM offset. I extracted this using the three calibration lines that were injected during the locking period: 131.7 Hz, 6000 ct into PR2; 183.7 Hz, 1000 ct into BS; and 152.9 Hz, 6000 ct into SR2.

In the following table, the first number in each pair is the magnitude (in ct/ct), and the second is the phase.

| PR2 | BS | SR2 | |

|---|---|---|---|

| RF27 | 7.6(1.2), 3.4(3)° | 0.29(6), 151.3(7.8)° | 0.07(3), -70(110)° |

| RF135 | 12.3(2.0), 139.7(4.5)° | 0.7(3), -84(35)° | 1.6(4), 6(14)° |