Nic, Evan

We went down to EY to see what was up with the green WFS on ISCTEY (D1400241). To start with, we decided to resteer the beams so that they are not clipping on any optics.

- We steered M14 so that the beam passed through the clear aperture of BS5 (before it was exiting too close to the BS mount).

- We resteered onto PD8 by touching L9 and L15. We got a factor of 10 more dc power on the PD this way.

- We moved M16 (a piezo mirror) slightly so that the beam is centered on the mirror, and so that it travels to M18 (also a piezo mirorr) parallel to the hole pattern on the table.

- We moved BS6 and L12 so that the beam passes cleanly through these optics.

- Using M17, we resteered onto WFS A.

- We moved L13 so that the beam passes through cleanly.

- Using M19, we resteered onto WFS B.

- We moved the iris between M14 and BS5 so that the splotchy beam from the Faraday isolator can be stopped down to something vaguely circular.

We also tightened down PD4, which had some issues with loose mounting.

Somehow, aligning the beam on the Green LSC PD gave us a factor of 10 more power.

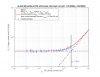

Attached, one may see the change in power on the green refl PD at end Y. The first shows just a few hours from today, showing the change in power.

Also attached is 2 weeks of trends, to see if the PD was well aligned in the past, and it was just bad this morning. As far as I can tell, the power from this morning was a common number measured by this diode. There are also times with the power larger, but the value is not stable. I'm not sure if this is when the arm is aligned. I will check once we again align the arm.

The WFS PZT centering servos were measured and tuned up. All DsOF have UGFs that equal to roughly 10Hz.