We've been having trouble isolating ITMX. The punchline is, I think I need to collect a new with the seismometers in low gain and redo the loops. The rest of this post is summary/posterity/flagellation.

-Last week, Sheila complained about the performance of the ITMX ISI.

-To fix this, I took a new transfer function, but in response to something somebody said somewhere, I used a different configuration than previous rounds. This time I left the T240 and L4C in high gain, where before I had usually run all the seismometers in low gain for the tf.

-I ran through all the commissioning scripts, load new cart matrices, new blend filters, new damping loops, and new isolation loops. Loading everything went off with no problems.

-Turning on the isolation loops was a different story. When I left on Tuesday, St1 was partially working, I never made it to St2. Kiwamu and Jaime were able to wrestle St1 into a semi functional state (alog 13746).

-I've continued to wrestle with this. JeffK suggested less aggressive loops, which I have spent a lot of time making successively more and more conservative loops. The first two attached images show a representative old and new loop. The old loop (that Sheila complained about originally) is more aggressive: higher UGF, more gain peaking, more aggressive boost, less phase at UGF (14 degrees!). The newer loop seems pretty "easy" in comparison, but it took a lot to turn it on, and it still rings a little.

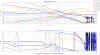

-Another clue, suggested by BrianL, comes from looking at the damping filters. The third image shows one of the loops from ITMY and ITMX. The ITMX loop has 7X less gain, but otherwise looks the same; phase looks the same. The 7X is suspicious, because that is exactly the difference in the gain between the high and low gain of the L4C. I had noticed earlier that the DAC outputs when the ISI was only damping looked low (i.e. never higher than a count, when I thought a few tens of counts was more normal).

-So, this afternoon, I tried turning up the gain on the St1 damping loops to 7x. The outputs of the DAC increased to what I thought were more normal numbers, and nothing went crazy. I tried turning loops on at this point, and it was still difficult, but eventually we got everything on for St1. Additionally, some of the ringing was alleviated by upping the gain on a few of the loops, so that is how I have left it. St2 is damping only still, but St1 has been running for the last 4-ish hours.

-I looked at the St1 & St2 seismometers, as well as the op-levs to compare these not-so-great loops and the just damped state and it looks like the current arrangement is a little better than just damping. My last 3 images are the op-lev spectra, and the St2 seismometers. Pretty sure the big peak at 30hz is Kyle's pump cart, so a temporary issue.

-I have scripts set to launch the tf at about 1 am. I may come in to work on this some more this weekend, I'll let the appropriate people know if I do.