Chris, Sheila, Alexa, Daniel,

This morning Chris rephased the ALS WFSs, and balanced the gains of the different sections. Results were verry sensitive to the cavity alingment, so a few iterations were needed. Then he measured the sensing matrix again several times, this also depends on the cavity alingment. These three measurements were with as good of an alingment as we could find by hand (phase in degrees in parens for those elements where the phase was inconsistent):

|

|

ETMX PIT |

ITMX PIT |

ETMX YAW |

ITMX YAW |

|

WFS A |

-944, -994, -1211 |

858, 807, 613 |

-61.8, -61.9, -59.3 |

1043(-27), 1043(-107), 1031(40) |

|

WFS B |

-580.2, -669, -877 |

766(15), 935(114), 801(-179) |

52.0(-132), 52.1(-123), 51.4(-10) |

568, 541, 570 |

With this information we zeroed out WFS B to ITMX PIT and ETMX YAW and WFS A to ITMX YAW, the elements where the phase wandered, and then inverted this. We also offloaded the WFS alingment signals to the top stage, to avoid saturating the DAC.

Chris has also written a script that centers the WFS using the picomotors. It is userapps/als/h1/scrpits/als_x_wfs_center.py

We have also written a wfs relieve script at userapps/als/h1/scrpits/WFS/alsWFSreleive.sh. This just relives the top stage, onto the offset of the M)_LOCK filter bank.

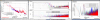

We were then sucsessfull in turning on all 4 DOFs, and we turned up the gain, we estimate that we got a ugf of 1 Hz for both of the Pitch loops. We made the attached measurement. In the left plot, the COMM noise measurement (no cavity pole removed) from monday night is the blue reference, and our measurement from tonight is in red. The rms down to 0.1 Hz is 10Hz, still almost 30Hz down to 0.02 Hz. We also have higher noise at 1-3 Hz, we don't know if this is caused by the changes to the WFS, or if it is just a difference in the ground motion. Because of the earth quake we aren't able to repeat the measurement without WFS right now, but we looked at some coherences to try to understand. The top panel in the middle plot shows that the oplevs have coherence with the WFS control signals up to about 1 Hz. We looked at some end X seismometer coherences and don't see anything (bottom panel of middle plot). The right plot shows that the oplevs do have coherence with the COMM Noise from 0.4-0.8 Hz.

This data is saved as COMM_NOISE_April_2.xml in my COMM folder (sheila.dwyer/ALS/HIFOX/COMM)