(Jax, Alexa)

Things that went well this weekend:

1. Alignment of components: the components on ISCTEY are largely in good alignment, with one exception - we ran out of time to align PD4 (faraday rejection/green laser power).

2. Fiber polarization is adjusted fairly well.

3. Beam scan of green input beam was taken for a baseline measurement for possible beam quality issues in the future. This scan was taken after PZT2 (wanted more points but getting the beam to nanoscan height was being difficult with what I had at the end station).

Things that did not go well this weekend:

1. PZT mirrors: the PZT mirrors move, but not as desired - there's some p/y coupling, especially in PZT2. The readbacks look questionable as well. Needs follow-up.

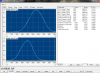

2. Acquisition of PLL beatnote: despite some pretty exhaustive alignment to the BBPD, there's no appreciable beatnote. Lots of alignment tweaks and laser temperature adjustments only led to us finding something weak on the laser at 750kHz.

Our working theory was that we're not getting enough power out of the fiber.

To the table: 75 uW

Onto the table: 65 uW

After PBS: 45 uW

After the splitter that brings it to the main path: 22 uW

This may or may not be enough power. Sheila suggested we might be saturating the PD with the laser light, but we're planning on taking a closer look at possible causes tomorrow.

In summary, lots of work got done, but there's lots left.