When we went into the chamber we have found that the top cable rounting was done in such a way that

-

Cables were loose and rubbing with each other,

-

Cables were rubbing with the cable loops inside the top mass,

-

One cable was touching the inside wall of the top mass hole from which the cables come out.

These are all bad, and I spent some time last week to divide four cables into two groups to make sure that none of the above was happening, but the cables were re-routed yesterday evening and they were bundled together without paying attention to the above.

Two of the four cables that go through the TMS top mass are for picomotors and are much thicker than BOSEM cables (the core diameter is bigger). These are stiff cables, and it's very difficult to route them such that they don't touch anything, and this is especially true for the pilot unit (TMSY) where the cable clamping inside the top mass is totally different from production units. How this is done has a big effect.

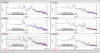

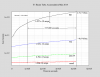

Attached are free swing spectra of three different cable routing. It's convenient to remember that there is a three-finger structure between 0.67 and 0.82 Hz.

Freeswing, this morning, ie cable rubbing (green).

-

Q of the 1.75Hz L resonance (top left) as well as 1.4Hz T resonance (bottom left) are really, really low.

-

Q of 2.4 Hz and 2.5Hz peaks are low though it's hard to see without zooming in.

-

The highest three-finger resonances (0.82Hz in this case) has a low Q.

Freeswing, after we made it the way we want it, no rubbing (blue).

We unbundled the cables, divided into three different routes (one route has two cables) and made sure that nothing is touching anything. This should be roughly the state of things from yesterday morning, except that the cables are divided into three instead of two (somehow it was very tough to do it right in just two routes today).

-

Qs don't suck. Three finger Qs good. All in all highest Q for most resonances.

-

But the resonances that used to suck, i.e. 1.4Hz and/or 1.75Hz split into multiple higher Q resonances.

-

Frequency shift for the ring finger and the middle finger.

I believe that this is roughly the same state we were in during OAT days (https://alog.ligo-wa.caltech.edu/aLOG/index.php?callRep=2587)

Freeswing, after we bundled cables together and used zip ties so that the cables at least don't rub against each other (red).

This is the state we're in now, as I wanted to see if zip ties help after we tested the blue configuration.

-

Q of the 1.75Hz and 1.4Hz suck.

-

Q of 2.4 and 2.5Hz peaks are better than in the morning.

-

Frequency shift for the ring finger and the middle finger.

So, all in all, I think we need to go back to blue state tomorrow. Note that free swinging spectra are not transfer functions. This is a good tool to detect rubbing/interference.