I am summarizing here recent progress on SEI units, and providing guidelines regarding what needs to be done next week.

Besides Guardian work on HAM-ISI (see Jamie's reports), most of the work has been focused on BSC-ISI units:

Blend Filters for the BSC-ISI

We have started to standardize the blend configurations. There are three sets of blend filters that we selected as useful for commissioning and/or operations. They are:

- A set of blend filters called "Start". This filter has a 750 mHz blend frequencies in all degrees of freedoms. It doesn't include the T240. It will be used to turn on the BSC-ISI units. Unlike other "750 mHz" blend filters used in the past, this one provide adequate CPS low pass filtering to not short cut passive isolation.

- A set of blend filters called "T750 mHz". It is based on the same set of complementary filters as "Start", but includes the T240s.

- A set of blend filters called "Tcrappy". This set of blend filters is based on Ryan's noise analysis and filter design work. It has been slightly degenerated to fit into one filter bank and therefore be compatible with our "turn on scripts". Rich named it "TCrappy" to emphaisze that it still needs to be refined.

All other sets of blend filters previously tried at LHO can't provide adequate isolation. We are in the process of removing them from all BSC-ISI units filter banks (see status chamber per chamber below).

BSC-ISI Conrtrol configs

We currently have two pretty good configurations that we are populating in all chambers:

Config 1: TCrappy on Stage 1 and Stage 2

Config 2: TCrappy on Stage 1, T750 mHZ on Stage 2, and sensor correction form Stage 1 to Stage 2.

See ETMX for an example of results comparison.

ETMX

- The three standard set of blend filters have been loaded in FM0, FM1 and FM2 respectively. All other blend filters have been removed.

- The sensor correction from Stage 1 to Stage 2 has been installed. Preliminary gain matching has been done. I found a gain of 1.15. A 15% calibration is a bit surprising. To be checked. It gives good results anyhow.

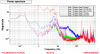

The top left plot of "ETMX.png" shows Stage 2 motion measured by the GS13s in the X direction.

The bottom left plot attached shows optical lever pitch motion, amplitude spectrale density.

The bottom right plot attached shows optical lever pitch motion, RMS.

The red curves are references with damping only.

The brown curves show the motion with the "config 1" (Tcrappy everywhere). It reduces the optical lever RMS motion from 600 nrads to 40 nrads.

The magenta curve shows the motion with the "config 2" (Tcrappy, T750 and Sens Cor). It reduces the optical lever motion from 600 nrads to 30 nrads.

It is interesting to note that the two configs offer very different compromise as seen by the GS13s. TCrappy provides better isolation at the Quad's pitch frequencies (~0.45Hz), but the sensor correction config provides a slithly lower RMS. It makes me think we have room to improve the compromise between the feedback and feedborward controls parameters.

No big winds in the past few days, so we'll have to wait to find out wether config 2 behaves well under high wind conditions.

To be done next on this unit :

- tilt decoupling on Stage 2. I have made a template in data/transfer_functions/Isolated. It uses filtered white noise designed to increase the SNR at frequencies of interest and speed up the measurement.

- gain matching optimization for the sensor correction

- Control levels 3

ITMX

The blend filters have been written into the filter file tonight. However, the filters have not been loaded yet to not disrupt ongoing decoupling measurements on the quad.

To be done next on this unit :

- loading the blend filters and test them

- Stage 2 tilt decoupling

- Sensor correction gain matching

BS Status

- The three standard sets of blend filters have been loaded in FM0, FM1 and FM2 respectively. All other blend filters have been removed..

- The sensor correction from Stage 1 to Stage 2 has been installed, but no gain matching has been done yet.

- The "BS.png" plot shows Stage 2 motion measured by the GS13s in the X direction. The red curves show the motions with both stages damped. The blue curve shows all the badness that was induced by the old set of blend filters. The green curve shows what we have with the new set of "Start" filters. The brown curve shows the motion in the "Tcrappy" configuration. The pink curve shows the motion with the "Sensor Correction".

- We have studied the BSC-ISI saturations occuring during the lock acuisition process. It has been reduced for the level 1 controller. We have good insight as for making further improvements.

To be done:

- tilt decoupling on Stage 2

- gain matching for the sensor correction

- Control levels status -> to be checked with Jim and Hugh

ITMY

Sheila encourages us to work on this unit as soon as possible, before it gets extensively used for IFO activities. It should be one of the top priorities for next week.

Control Scripts:

I have made V4 folders for BS, ITMX and ETMX

Made and commited modifications to routine 6.

A general comment I am posting here for the records:

We need indicators at the top level screens showing whether electronigs are in the good gain and whitening states. I got caught several time in the past days.

Hugh and/or Jim, Jeff, Arnaud would know details I may not have captured here. Sebastien will be there to help next week.

The vertical position is actually high by 0.9 mm, not by the 0.35 mm originally stated.