Kiwamu with remote help from Rodica

I completed two missions as a part of the high power prep:

-

I have installed the motorized rotational stage in the main path on the PSL table.

-

I increased the laser power of the ALS doubling path by a factor of 10 while maintaining 1W incident on IMC.

Some pictures are available in ResourceSpace: https://ligoimages.mit.edu/?c=1434

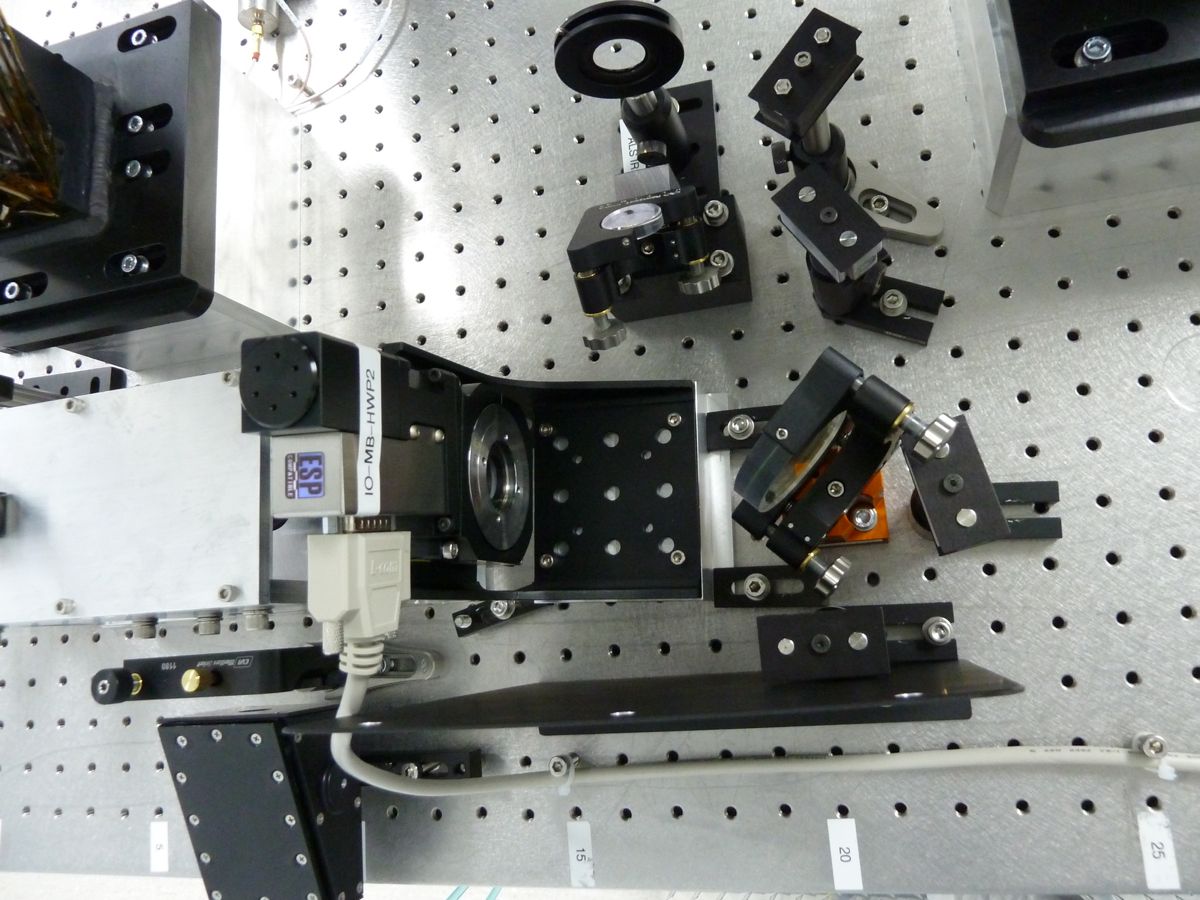

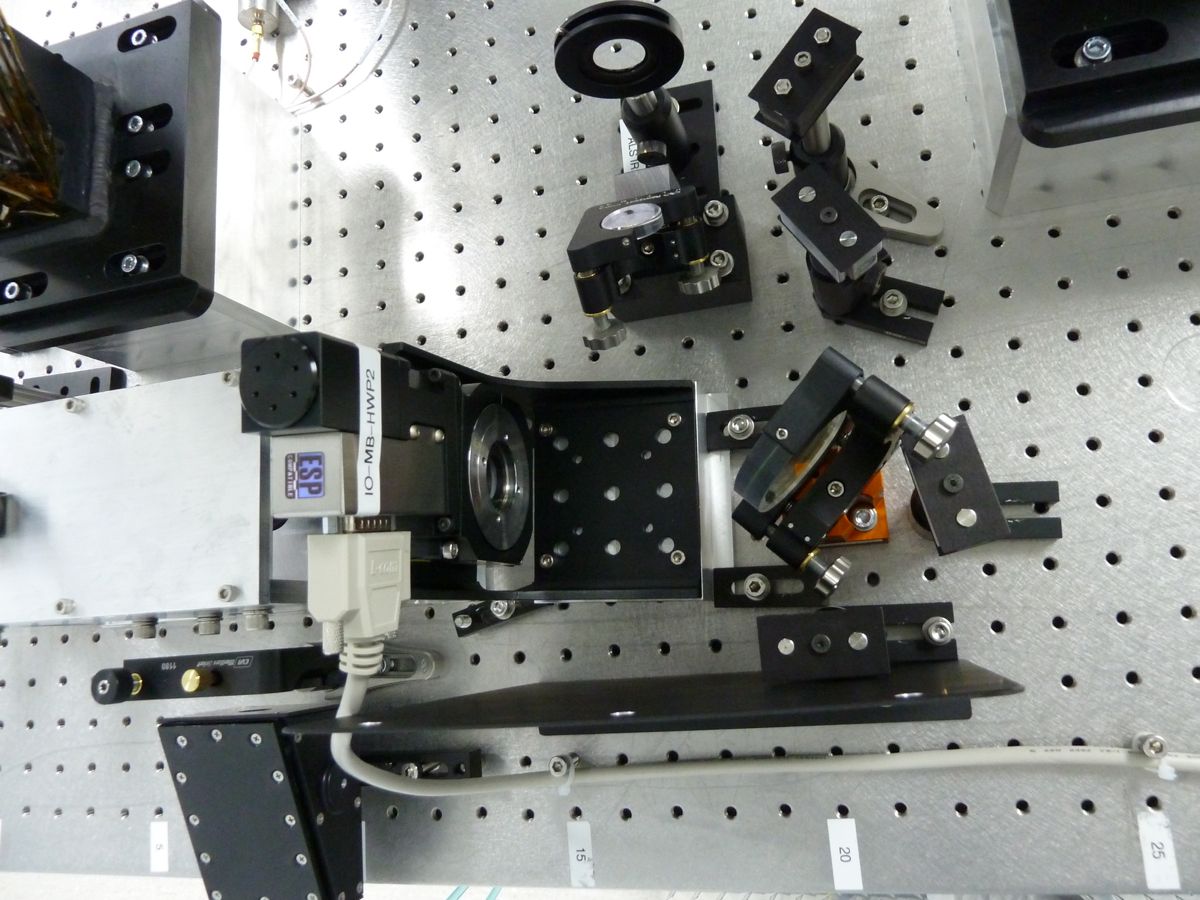

Installation of the rotational stage:

The stage had been ready and sitting on the table for a long time (see alog 8731). First of all, I took the fixed-manual stage out of the main path. Then I removed the wave plate out of it and put it in the motorized stage together with a pair of the white rings which were also the stuff I took out from the manual stage. The motorized stage was then moved to the same place as the old wave plate had been. The position was fine-adjusted such that the beam goes through the center of the wave plate.

Power increment:

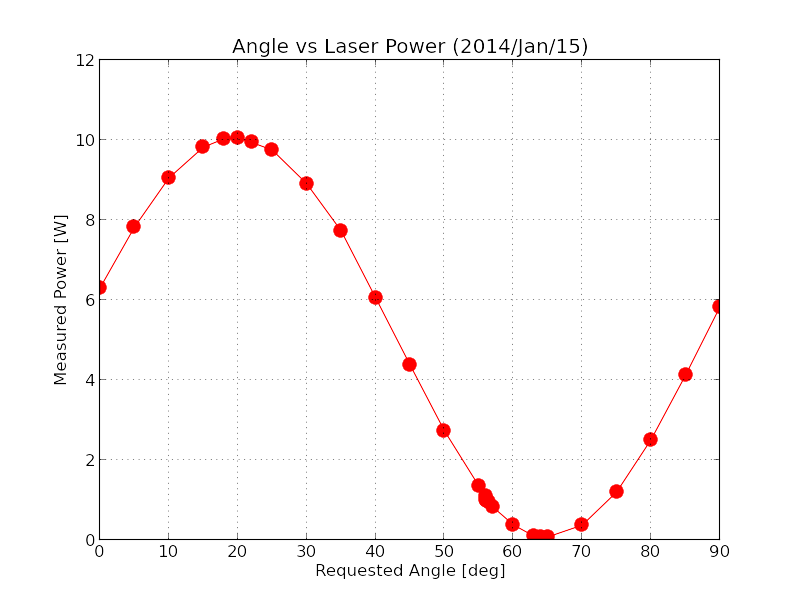

I rotated the wave plate which resides between PMC and the EOM to increase the laser power to 10 W. The idea is to give some more power into the ALS doubling path (see alog 9287) while mantaining the incident power of IMC to be 1 W. This means the new rotational stage is the one which decreases the laser power from 10 to 1 W.

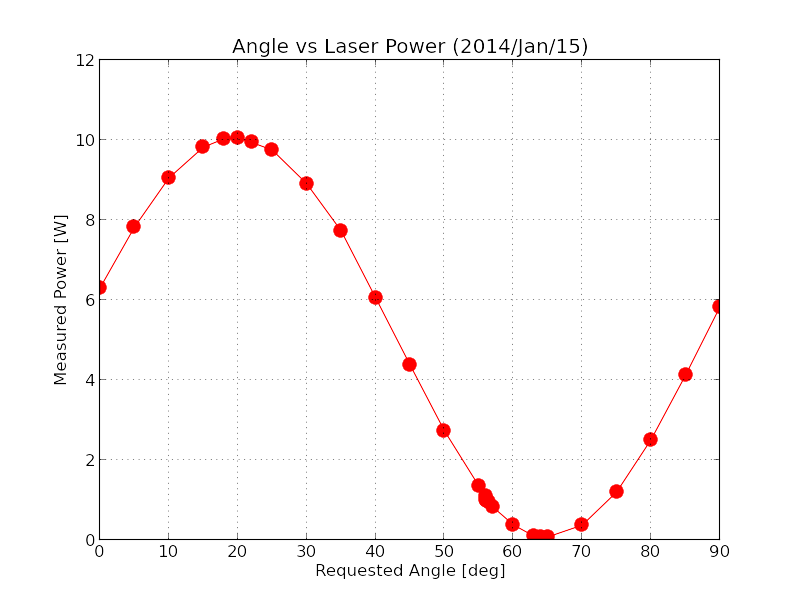

In order to set the angle of the rotational stage right, I measured the laser power which would be incident on IMC as a function of the rotational angle. The result is shown below and also the raw data is attached.

According to this measurement, I set the request angle to be 56.1 deg in the medm screen. Plus, to always keep this angle until we are fully ready for 10 W, I physically locked the interlock switch of the rotational stage, so that the power can not change by accident.