· HAM 1

o HEPI unlocked and running

Ongoing low priority testing

One L4C needs to be replaced: H2

One actuator is weak: V4 It is 20% weaker than its counterparts. Likely clogged. May require replacement further down the line.

· HAM2

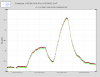

o ISI: previously commissioned with HEPI locked (recent performance spectra), currently unlocked, in vacuum

o HEPI: to be commissioned, currently locked, models and electronics ready. Commissioning could start once HEPI is unlocked.

· HAM 3

o ISI: previously commissioned with HEPI locked (recent performance spectra), currently unlocked, in vacuum

o HEPI: To be commissioned, currently locked, model and electronics ready. Commissioning could start once HEPI is unlocked.

· HAM 4

o ISI: In chamber, Previously tested during assembly validation, currently locked, no suspension installed, in-vac cables not connected.

Electronics ready, in field cables ready, in-rack cables ready. Temporary STS cables

Simulink Model was created.

Model is running, and MEDM screens are available in the Sitemap.

o HEPI: Currently locked, to be commissioned

Electronics ready, in field cables ready, in-rack cables ready. Temporary STS cables

Simulink Model was created.

Model is running, and MEDM screens are available in the Sitemap.

· HAM 5

o ISI: In Chamber, Previously tested during assembly validation, currently locked, no suspension installed, in-vac cables not connected, chamber temporarily closed.

Electronics ready, in field cables ready, in-rack cables ready. Temporary STS cables

Simulink Model was created.

Model is running, and MEDM screens are available in the Sitemap.

o HEPI: Currently locked, to be commissioned

Electronics ready, in field cables ready, in-rack cables ready. Temporary STS cables

Simulink Model was created.

Model is running, and MEDM screens are available in the Sitemap.

· HAM 6

o ISI: Chamber-Side testing complete

getting ready for installation in chamber.

Electronics ready (Corner 2 CPS interface damaged by faulty cable, will be replaced today), in field cables ready, in-rack cables ready. Temporary STS cables

Simulink Model was created.

Model is running, and MEDM screens are available in the Sitemap.

o HEPI: Currently locked, to be commissioned

Electronics ready, in field cables ready, in-rack cables ready. Temporary STS cables

Simulink Model was created.

Model is running, and MEDM screens are available in the Sitemap.