[Cheryl, Giacomo]

A couple of IMC activities were started today and not completed:

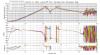

- the setup for the measurement of the cavity pole was prepared: using an SR785 signal analyzer, a swept sine is injected in the "inner loop transfer function input" on the PSL ISS front end on the field rack. The output of one of the ISS PD (A or B, we used the one that is not used int he loop in loop) is taken from the same field rack and sent to one of the channels. A Thorlabs PDA100A photodiode sits on the IOT1 table and is connected to the other channel fo the signal analyzer using one the the (unfortunately currently available) WFS RF cable. The PDA100A is put in the REFL path with the IMC both unlocked and misaligned to measure the relative TF of the two PD. Then it is moved to the TRANS path, the IMC locked, and the measurement repeated. The ratio of the two TF should give the IMC transfer fucntion. A quick measure was taken late this evening, but it still needs to be analyzied (and checked for errors).

- with the goal of computing a power budget, we checked if all the beams were coming out pretty much in the expected positions:

- the forawrd and backward beams were coming out from their (common) viewport pretty much in the expected positions (they pretty much covnerge at maybe 20 inches from the viewport).

- the parking beam was not visible, and it seemed to be clipping on the baffle right in front of IM4.

- IM3 and IM4 also showed to have drifted during pumpdown in pitch and yaw, much more thean IM1 and IM2. Note that bringing them back to the "in-air" positions (as read by the OSEMs) did not make the parking beam reach its target, and apparently spoiled the position of the IM4 forward and backward transmitted beams (they were still coming out of the viewport, but convergin much farther away)

We played with the IM suspensions to try to reroute the parking beam to its intended location, but we started late due to other activities going on and we only got to the point in which the beam is badly clipped by the parking baffle (but at least is visible!). We are not far, but not quiete there yet. We'll resume next week.