TITLE: 05/19 Day Shift: 1430-2330 UTC (0730-1630 PST), all times posted in UTC

STATE of H1: Lock Acquisition

INCOMING OPERATOR: Tony

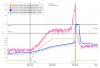

SHIFT SUMMARY: More progress than yesterday in terms of the PRMI oscillation as I seem to have solved it for now by adjusting loop gains and ramps and can hold it locked, then I was back to DRMI not being able to lock but after Sheila restored PR3 to a previous spot we were able to lock DRMI no problem. Currently a few minutes away from NLN

15:00 UTC Initial Alignment as there weren't really any flashes on PRMI

After some more fiddling with gains/ramp times and talking to Sheila I was able to stop the PRMI 20ish Hz buzz by reducing PRMI-MICH to 2.2 from 2.8 and increasing PRMI_PRCL to 8 from 6 and set the ramp time sof both to 5 alog77928

20:25 UTC - No matter how much adjusting I did with the sliders (BS, PRM, SRM) I couldn't get AS AIR looking good enough so I thought there must be an alignment issue somewhere after a few mores tries I dropped to do another Initial Alignment, after this I still had DRMI issues.

I further decreased the gain of PRMI-MICH to 2.0 after Sheila looked at my OLG measurement, PRMI locked pretty easily after this. We're not sure why my PRCL OLG measurement looked the way it did alog77929

22:35 UTC Sheila adjusted PR3 to where it used to be, after which I did another Initial Alignment so we could try locking PRMI. I may need to revert my PRMI loop changes? I have not reverted them as of now

After finishing IA we locked DRMI immediately

There were a lot of IFO_OUT saturations during POWER_25W and MOVE_STOPS