[Peter, Koji]

Follow up entry for ALOG LHO 41420

Optical Transmissivity of the EOM

The optical power was measured before and after the EOM. Because of the space constraint, the "BEFORE" and "AFTER" measurements had an HR mirror and a 2" lens between the power meter and the EOM, respectively.

OLD EOM: T_EOM = 175.0mW/177.8mW = 0.98 +/-0.01

NEW EOM: T_EOM = 178.3mW/180.0mW = 0.99 +/-0.01

We did not find any significant change of the transmission performance for the new eom.

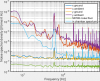

Modulation depth

The modulation depth of 9.1MHz and 45.5MHz modulations were measured with an OSA. The other two modulations were too small to measure. The OSA output was captured with a digital oscilloscope with one channel adjusted for the carrier peak and the other for the sideband peaks. The offsets (PD dark, Vofs between the channels) were subtracted in the analysis. 10 scans were taken for each case, meaning N=20 samples for one modulation with upper and lower sidebands combined. Driving RF power for each case is described in the following section.

OLD EOM 9.1MHz: m = 0.187 +/- 0.001 [rad] (N=20)

OLD EOM 45.5MHz: m = 0.287 +/- 0.001 [rad] (N=20)

NEW EOM 9.1MHz: m = 0.210 +/- 0.006 [rad] (N=20)

NEW EOM 45.5MHz: m = 0.197 +/- 0.007 [rad] (N=20)

The modulation for 9.1MHz was adjusted to have approximately the same number as before.

The modulation for 45.5MHz got maxed out with the driver capability together with the additional loss at the power combiner (see below)

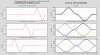

Driving power

The RF driving power levels for the above modulation depths were measured. The RF signals at 24.1MHz and 45.5MHz are combined with a power combiner (RF-Lambda / RFLT2W0002GN).

OLD EOM 9.1MHz: EPICS setting 16.8dBm / Delivered RF 16.68dBm

OLD EOM 45.5MHz: EPICS setting 23.4dBm / Delivered RF 23.36dBm

NEW EOM 9.1MHz: EPICS setting 23.6dBm / Delivered RF 23.56dBm => Estimated modulation 0.191 rad

NEW EOM 118.3MHz:Delivered RF 9.84dBm => Estimated modulation 11.7 mrad

NEW EOM 24.1MHz: The cable in the PSL 14.12dBm -> (ATTN at the amp input: 5dB) -> Amplifier output 28.98dBm

-> Power Combiner output (Derivered RF to the EOM) 24.6dBm => Estimated modulation 12.7 mrad

NEW EOM 45.5MHz: EPICS setting 27.0dBm (maximum setting) -> Driver output 27.3dBm -> Power Combiner output (Delivered RF to the EOM) 23.76dBm

=> Estimated modulation 0.210 rad

Note1: Daniel mentioned that the amp gain was supposed to be 16dB. However, the gain of ~20dB was observed.

Please check if this is OK. Is the output too big for the amplifier used?

Note2: The power combiner is causing the estimated loss of 4.4dB and 3.5dB for 24.1MHz and 45.5MHz respectively.

Attachment 1: Installed EOM

Attachment 2: Driver arrangement beneath the PSL optical table.

Attachment 3: Power splitter isolation (I didn't like that the power splitter connectors touching the amplifier chassis, which may cause some glitches.)

Attachment 4/5: Old EOM Input/Output surface (Microscope view, a few particulates visible, but the surfaces aregenerally in a good condition.)

Attachment 6: Mod. depth meas, an example scope screenshot.

Why is the power combiner not screwed to the output of the 45MHz amp?