The EE guys straightened me or the gear out, likely the former, and I was able to center the T240 at EndY today. This seismometer is currently on the floor just +X,+Y of the BRSY and wrt the ISI STS is +1mX, =Y. Anyway, if it performs okay, I'll move it into the BRS thermal housing exchanging it for the STS that I haven't gotten to do run well enough of late.

The first attachment shows the ground seismos and the BRS. Two hours show the T240 coming online around the large centering excursions; the ISI ground STS with my VEA movement; and the BRS getting rung up and now nicely quieted.

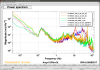

The second attachment is the current spectrum of the T240 channels and the ISI STS. The thin red and blue REF lines are the bad STS after the glitching stopped but it still was not matching the ISI STS--see 34198 for its lack of comparison. The current traces for ADC_0_ are now the T240 and you can see that it matches the ISI STS much better down to 10s of mHz. The lowest frequencies will be poor while the instrument thermalizes and we don't [care] too much about the stuff above 10Hz or so. [I can't vouch for the calibration yet for comparison to the STS but it is pretty good at the useism.]

On Tuesday if it continues to do okay, I [will] swap it in and it will likely then need a day or so to be ready for use--again further thermalizing.