(All time in UTC)

15:42 Wind picking up speed reaching 40 mph. BNS range is dropping slightly.

16:00 Lockloss. Wind reaching 50mph.

16:05 ODC observatory mode didn't bring itself out of OBSERVING. Stayed there for 5 mins before I realized it.

16:06 Took the interferometer to down after several locklosses before DRMI.

17:00 Rich to LVEA

17:11 Attempted locking failed

18:04 Rich back

19:57 Nutsinee driving down X and Y arms to check on tumbleweed.

20:25 Nutsinee back

20:28 Wind reading 60 mph. Locking won't be possible for a while.

21:08 Kiwamu and Rich to CER

21:30 Rich back

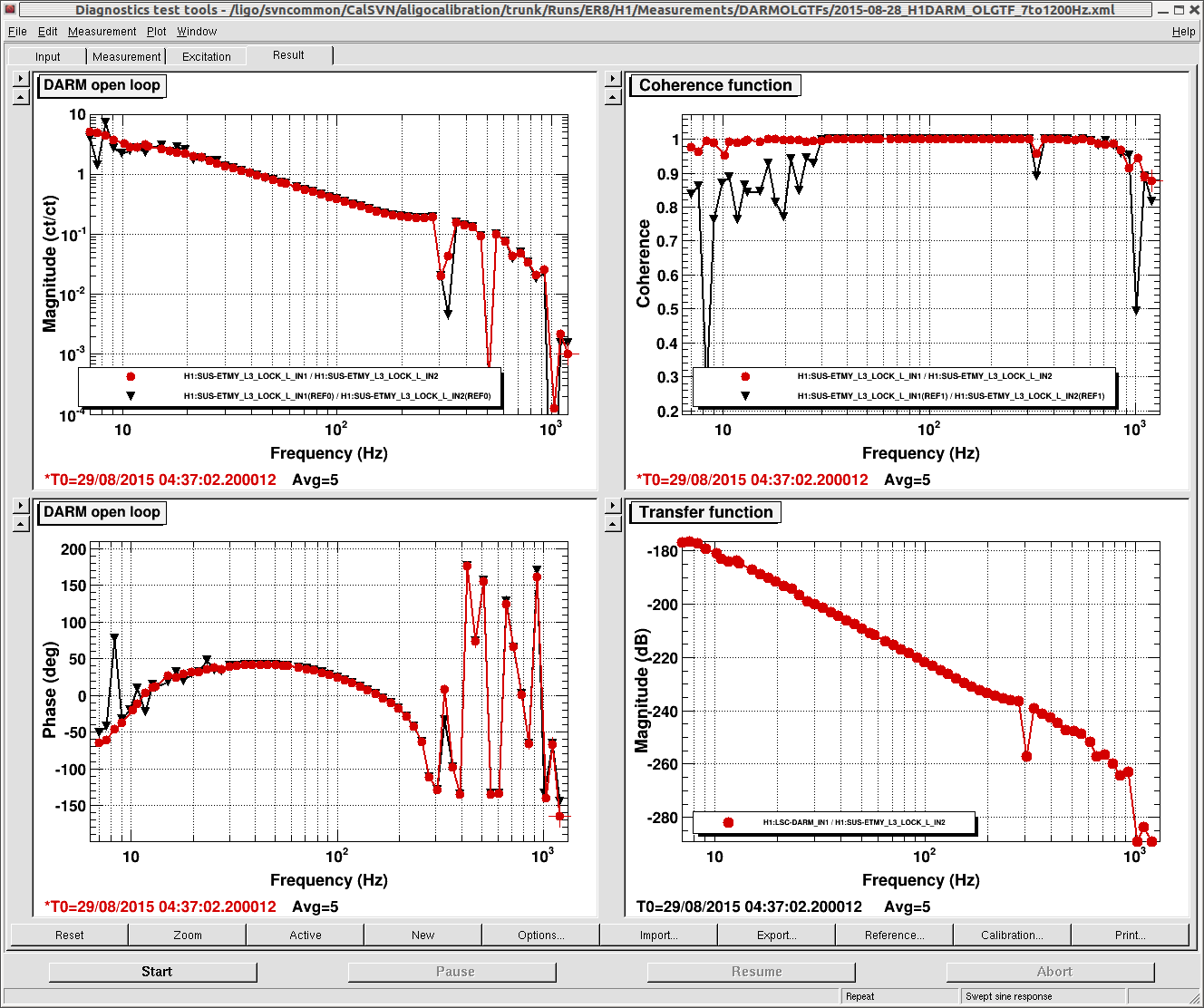

22:30 Kiwamu doing some electronic works. IMC will be on and off.

Other notes:

- EY dust alarm went off. >0.3u reads 16028.6 PCF, >0.5y reads 1285.7 PCF at the time.

- As Daniel requested, I added graphics indicate operating mode on the Ops Overview. The graphics visibility is calculated using H1:ODC-OBSERVATORY_MODE. I haven't had a chance to test if it works properly but so far the "environment" badge shows up as it's supposed to.

- Tumbleweeds are flying! Slowly accumulating along the X arm but still far from blocking the road.

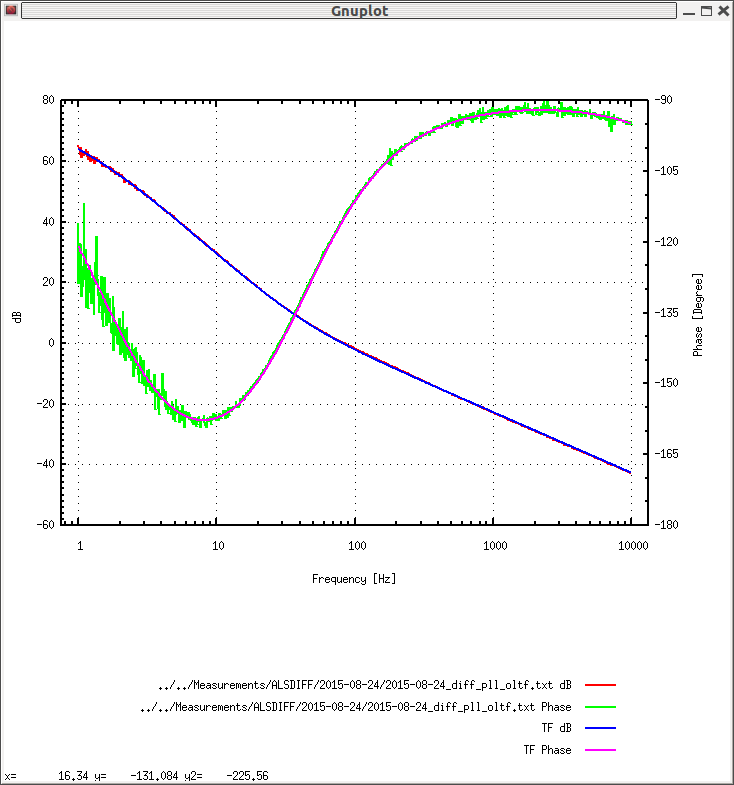

- We haven't had a stable lock since the wind reached 40mph.