Lisa, Evan, Sheila, Keita, Jim W, Kiwamu,

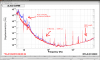

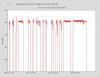

Today we had an issue in which the Y end PDH loop kept unlocking due to a high longitudinal motion (more than 12 um peak-to-peak at 50 mHz). The wind was high at 20 mph on average with 40 mph at highest most of the time today starting from 9 am local. In this report I attempt to summarize the issue associated with today's windy condition.

(Y arm motion was too high)

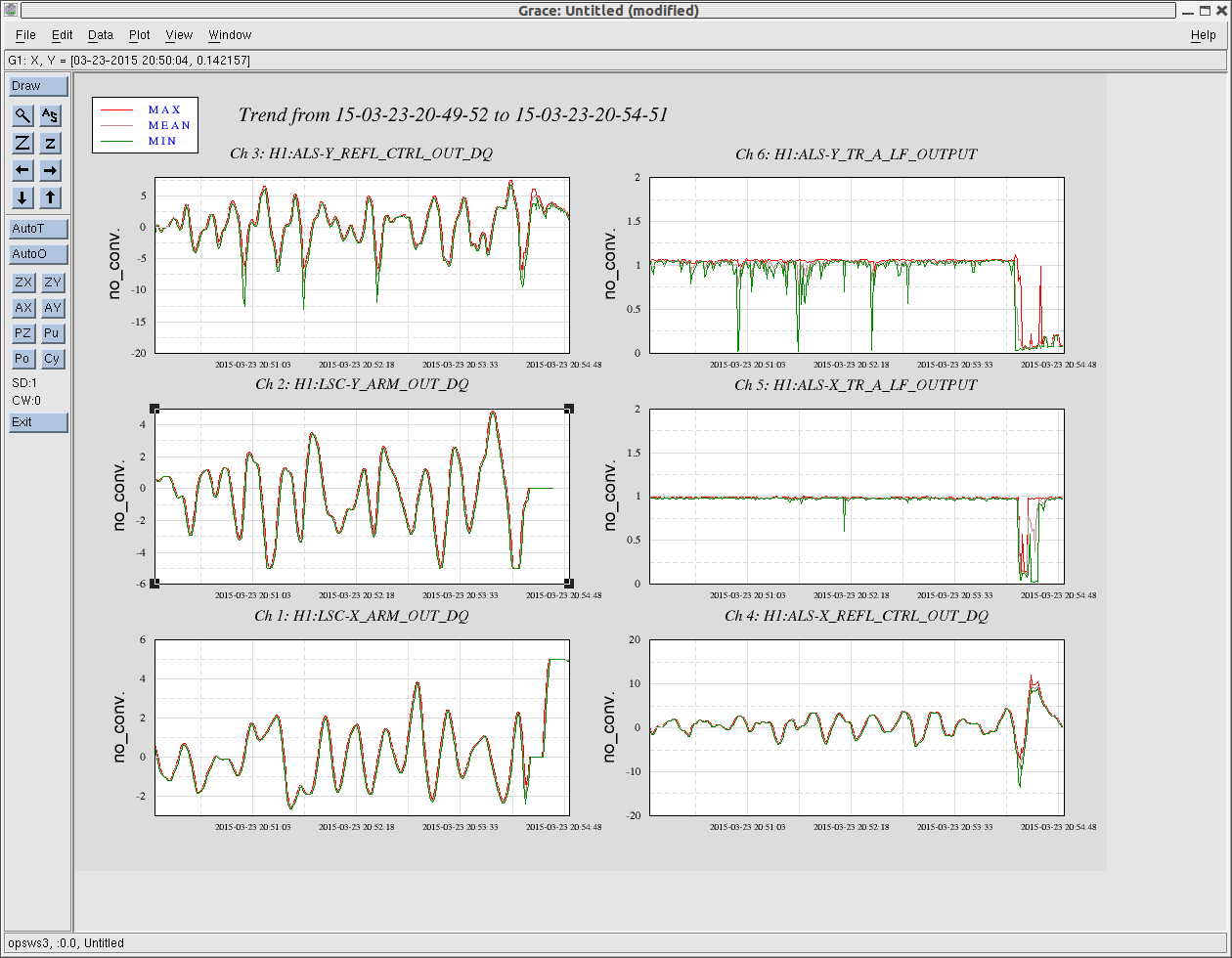

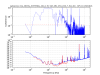

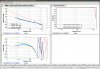

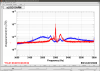

When we started fully locking the interferometer, we noticed that the ALS loops frequently dropped their locks in the middle of the locking sequence. It turned out that the Y arm motion was so high the end VCO saturated in every several minutes. The X PDH also had a similar amplitude but it was slightly smaller than that of the Y arm by ~ 20% which barely allowed the X arm to stay locked. The attached is a 5 minutes trend of relevant channels under a condition that:

- without ALS diff loop.

- without ALS comm loop.

- with local tidal feedback loops on X and Y arms with UGF of about 0.03 Hz for both loops.

- ISI ETMX stage 1 is in 90 mHz blend configuration without the BRS correction

- ISI ETMY stage 1 is in 90 mHz blend configuration.

As shown in the plots, the Y arm PDH control signal (ALS-Y_REFL_CTRL_OUT_DQ) went up and down at a frequency of 50 mHz. This channel is calibrated into the Y arm displacement in um. When it went below -7 um or above 7 um it unlocks essentially because the end VCO rails. The X arm showed a similar amplitude, but amplitude was not as big as that of the Y arm. The X arm dropped the lock less frequently than the Y arm.

(Some attempt with a high band width tidal)

We then started increasing the bandwidth of the local tidal feedback which picks up signals from the end PDH control and offload it to the L1 stage of ETMY. The idea is that we wanted to physically quiet down the ETMY motion so that the VCO can stay within the range. We increased the gain of both X and Y local tidal loops by a factor of 3. So their UGFs are now 0.1 Hz. At the end the attempts, the wind incidentally came back down to 10-30 mph so we can not really say if this scheme helped.