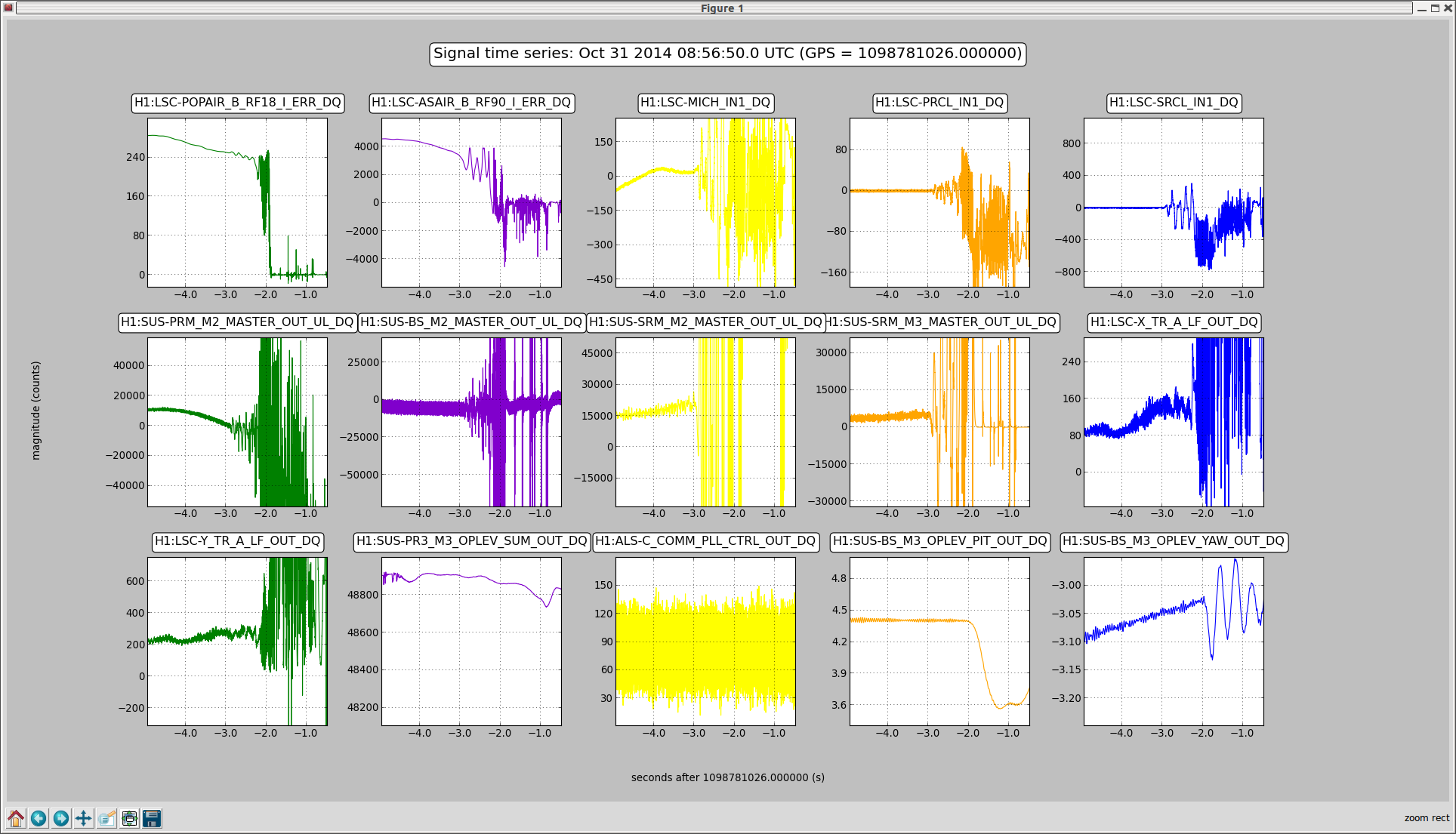

The table below shows a comparison of the optical levers motion meaured during the five mornings of this week. We used ETMX to evaluate several configurations:

- Monday Oct 27, 3am - 4am, ETMX Stage 1 Z in Low Blend, Sensor Correction Off

- Tuesday Oct 28, 3am - 4am, ETMX Stage 1 Z in Low Blend, Sensor Correction Off

- Wednesday Oct 29, 3am - 4am, ETMX Stage 1 Z in High Blend, Sensor Correction Off

- Thursday Oct 30, 3am - 4am, ETMX Stage 1 Z in Low Blend, Sensor Correction On

- Friday Oct 31, 3am - 4am, ETMX Stage 1 Z in Low Blend, Sensor Correction On. BS sensor correction also ON (BS servo still engaged)

(Jim, please correct if my description of the controls configurations is inacurate)

Results: optical levers RMS motion

ETMX (Pitch/Yaw) Other test masses average (Pitch/Yaw) BS - Op Lev servoed (Pitch/Yaw)

Monday 15nrad /20nRad 30nrad / 30nRad 20nrad / 10nRad

Tuesday 20nrad / 35nRad 35nrad / 35nRad 15nrad / 35nRad

Wednesday 100nrad / 15nRad 40nrad / 35nRad 15nrad / 10nRad

Thursday 12nrad / 10nRad 30 nrad / 40nRad 13nrad / 10nRad

Friday 30 nrad / 10 nRad 30 nrad / 30 nRad 50 nrad / 50 nRad

Comments:

- On Monday and Tuesday, ETMX pitch motion was better than the other test masses, even though using the same configuration

- Wednesday results on ETMX show why we need to blend low on Stage 1 Z to reduce the pictch motion (at the cost of amplifying Yaw)

- Thursday results on ETMX with Sensor Correction On are excellent. The angular motion is as low as on the BS that is servoed.

- Friday results on ETMX are not as good in Pitch as the night before, but it is still much lower than usual in Yaw. The angular motion BS is very high. We might want to disable the op lev servo while testing the sensor correction on this unit. Jim is about to comment on BS sensor coreection activities.