Follow up to alog 14245

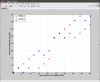

Checked the ETMy oplev laser diode current (measure w/ a voltmeter attached to the current monitor port on the back of the laser) and found the diode current was oscillating at about the same 0.3 Hz frequency of the QPD SUM out. Classic sign of one of these lasers failing. I swapped the failing laser (SN 199) with a new one taken from 3IFO stock (SN 104-1) and this oscillation went away (see attachment). As can be seen, the oscillation is gone, but there appears to be a slow ramp up time after the switch. I think this is the laser coming to thermal equilibrium, but will keep an eye on it in case it's not and there's something wrong with this "new" laser. If anyone else notices something not working right wth this oplev, let me know.

Also, after talking with Sheila to make sure this would not interfere with any commissioning activities, I re-aligned the ETMy oplev after the laser swap. The yaw output was getting very close to the end of the linear range of the QPD (yaw was reading -46 µrad, linear range ends around ±50 µrad), so any data was of questionable utility. When I left the end station at about 2:00pm PDT, the oplev signal read 0 µrad in both pitch and yaw.