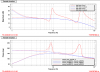

I left the ISI just damped with the HEPI loops closed. SEI tripped at 2027pdt. The ISI went on L4C levels 2 seconds before the HEPI tripped for Actuators... Maybe this makes sense compared to the previous trips where the ISI trips earlier wrt the HEPI when at least one stage of the ISI is isolated--when the ISI is isolating, it rings up its actuators faster as it drives in response. Again, clear 8ish hz ring up on all the HEPI/ISI signals.

Looking at the TF/Coh between HEPI out & ISI L4C as expected there is coherence; the magnitude of the TF is reduced with the X & Y HEPI ISO Boosts are disabled. Wait that makes sense as the ISI isolation is quieting the L4C...

Tested enabling the boosts. Independently enabling either X or Y boosts rings up and trips the ISI within a minute or so. While there is no foton magnitude difference between ISOL filter with and without boost, there is a 20 degree phase difference.

Given that the trip happens with just ISI damping and the boost seems to hasten things when the ISI is Isolated, JeffK recommends check for plant changes at ETMY HEPI.