Today I spent some time working on the automation of the dither alignment using guardian. I think this should be working OK now, we can try using it for a while and see how this goes.

We need a signal to keep the X arm on resonance when we are working with the Y arm, because the michelson signal contaminates REFL_9 when ITMY is aligned. Today I switched the refl bias path over to using the transmitted X arm power to lock on the side of fringe. The attached screenshot shows the settings in the LSC matrix. Stefan had the nice suggestion of using schmidt trigger to acquire this. The transmitted power is normalized already, so the calibration into Hz is just multiplying by the FWHM of the cavity, 84Hz., done is LSC REFL BIAS. The offset in this filter determines where we are on the fringe.

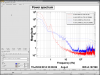

The gain is now set to give this path a crossover with the ALS COMM signal at 35 Hz, (Kiwamu's simulations have us using 30Hz crossover for this). The gain of this path is attached.