(Caveat: Since the alignment was not really touched up, alignment fluctuation might be coming into play. Wait for WFS commissioning for a better data.)

Jan Pold asked and here it is.

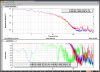

1 Watt into MC. The transmission is monitored with IM4 transmission QPD as well as MC2 transmission QPD.

The whitening gain for both of the QPDs were 18dB (though I could have set it higher I don't think that would have made any difference).

Three stages of whitening filters were used for both: For MC2, it is a fixed one stage (0.4:40) plus two stages of switchable (1:10), and for IM4 since the fixed stage was not present I used all three switchable stages.

60Hz comb filter was turned off.

The input to each segment before dewhitening was 1000 to 6000 counts (mostly AC), so it's decent.

The beam was not centered at all: For MC2, [P,Y]=[0.14, 0.55], and for IM4 this was [0.22, 0.07].

Anyway, the spectrum was measured for SUM_IN1_DQ channel, divided by DC and plotted. The data was saved as

/ligo/home/controls/keita.kawabe/RIN

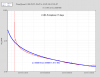

I and Cheryl went to the floor, MC was locked, and PRM was aligned so the IFO REFL is centered on the baffle hole before HAM1.

New "aligned" value for PRM alignment slider is [P,Y]=[-730, 0] urad.

This used to be [-830, -50] in air, the change is quite small considering the fact that we're under vacuum now.

With this data even the most serious skeptic should agree that the IO alignment is OK. We should proceed to center IM4 and MC2 trans QPDs because they're quite off-center now.