New damping filters installed on ETMY main chain (version 2.1).

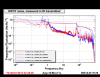

From now on, the gain value will be included in the "rolloff" filter, and the extra "lock" filter is included in "boost". The sign convention is -1 (cf attached picture).

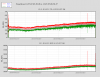

Attached is a spectra of top mass osem sensors in the longitudinal degree of freedom, comparing damped spectra with old set of filters, new one and with the suspension undamped.

Tomorrow, I will take an open loop transfer function and plot it against the model. Also, I will need to update the ODC "M0 damp state" bit status.

A new safe.snap has been commited on the svn.

Filters installed from matlab using autoquack

The filters were installed in foton using the matlab "autoquack" function in the script "prepare_toplevel_damping_filters.m" located in /ligo/svncommon/SusSVN/sus/trunk/QUAD/H1/ETMY/SAGM0/Scripts/

For now the script ONLY works for etmy top level damping filters, but will soon be modified to become more generic.