To date and the best of my knowledge, the only measurements of the 18-bit DAC noise have been those performed by J. Heefner, documented in T0900338, where the DAC noise is quoted as 150 [nV/rtHz] (and flat in the frequency band he probed). We'd learned from eLIGO (lessons by Tobin, myself,Matt, and Nic) that a DAC's noise floor changes when excitation is present, so Jay had measured the DAC noise while injecting a single-frequency line at ~100 [Hz], and then measured the high-frequency asymptote (his plots are on a linear x axis, without a grid so one can really only see the results above 100 Hz).

In the interest of suspension performance in the 0.1-10 [Hz] band where cavities are currently sensitive to their optic's motion, I've now characterized the noise in detail at low-frequency (0.05-1e3 [Hz], with focus on 0.05-50 [Hz] band), using a realistic output spectrum as the requested voltage. The results are attached and described below. Since the results are clearly non-linear, we may need to try different input spectra (working a little harder than I did to balance the SR785 range vs. noise) to really understand it. Naturally, we should also develop a model of the quantization noise, to see if we can differentiate this from just bad, non-linear electronics noise. Finally, we should also perform this same measurements on a 16-bit DAC.

Note that, by default, the user-model-to-IOP-model exchange is done with zero-padding, as has become the default configuration for all models.

--------

Plots and Captions

2013-07-21_2119_H1SUSMC2_DACOutput_ModeCleanerLocked_ASDs.pdf

During a fully functional Input Mode Cleaner lock, this is the output voltage requested of the DAC at all three stages. The spectra seen at the TOP/M1 stage is totally confusing to me, so I ignored it, as it was distracting to this study to try and figure out. More on that to come later. As such, (and also informed by the input range vs. noise floor of the SR785 at these frequencies), I chose the Middle / M2 stage spectra as my representative spectra.

experimentalsetup.pdf

Diagram of how the experiment was set up. For this study, I commandeered the H1 SUS QUAD Test Stand. This is a fully-production quality test stand, running up-to-date software, and up to which nothing is hooked, so it was the perfect test bed. The Pomona box that was used to switch between output channels (borrowed from MIT) was a easy, convenient way to grab the signals, keeping them shielded, without having to mess with the usual breakout boards and clip leads -- a set up usually fraught with excess unwanted noise.

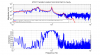

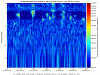

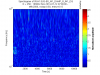

2013-07-21_H1SUSQUADTST_DACNoise.pdf The Results

PG1: Here is the digitally requested spectrum, calibrated into voltage out of the AI filter (i.e. cts at the COILOUTF_??_EXC point, multiplied by the gain of the DAC, 20 / 2^18 [V/ct]). It is compared with the measurement noise floor (for the low-frequency, 0.05 - 50 [Hz] band, with -10 [dBVpk] SR785 input range), and the measured DAC noise with no digital output requested. The "traveling notches" in the requested drive are used to carve out at the DAC noise without disrupting the main frequency content of the signal. Note that because of SR785 range vs. noise issues, I sent out a requested signal with a factor of 10 less RMS voltage at 1e-2 [Vrms]. This is compared with the M2 stage (with 1e-1 [Vrms]) and

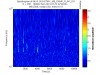

PG2 - 4:

The measured DAC noise output at the AI chassis for 3 DAC channels. We see, rather obviously that none of the notches below 10 [Hz], indicating a several elevated DAC noise floor. I've included a quick by-eye fit to the noise, which indicates that the DAC noise is 6e-6 * (10 [Hz] / f) [V/rtHz], with this excitation.

Notes:

- Even though the SR785 measurement is focused on the 0.05 - 50 [Hz] band, the full spectrum out to several [kHz] is requested during all measurements.

- It's unclear to me why the shape and level of the DAC noise changes when I switch to the higher measurement band (10 to 810 [Hz]). Since I saw the DAC noise floor after the natural 100 [Hz] roll-off of the output spectra while retaining the 30 [Hz] notch (and it was Sunday at 8pm), I didn't bother traveling the notch any further, and therefore only have one measurement for each channel in this band.

-----------

Details:

The template for the mode cleaner output request spectra can be found here:

${SusSVN}/sus/trunk/HSTS/H1/MC2/Common/Data/2013-07-21_2119_H1SUSMC2_DACOutput_ModeCleanerLocked_ASDs.xml

The input spectra is defined by the following AWGGUI Foton String which filtered white ("uniform") noise:

amplitude = 100000 to get 1e-2 [Vrms]

zpk([1.3;1.3;1.3;1.3;1.3;1.3],[0.3;0.3;0.3;0.3;0.3;0.3],1,"n")ellip("LowPass",4,1,80,100)

notch(0.47,10,200)notch(0.5,10,200)notch(0.52,10,200)

notch(0.9,10,200)notch(1,10,200)notch(1.1,5,200)

notch(4.7,10,200)notch(5,10,200)notch(5.2,5,200)

notch(10,5,200)notch(11,5,200)notch(12,2.5,200)

notch(30,5,200)notch(32,5,200)notch(34,2.5,200)

I'm *sure* there's a more elegant way of defining it, but ... so it goes.

The captured digital output spectra templates can be found here:

${SusSVN}/sus/trunk/QUAD/H1/QUADTST/Common/Data/18Bit_DACNoise_2013-07-21/

2013-07-21_H1SUSQUADTST_DACNoise_COILOUTF_AvgASDw0p45-0p5-0p55HzTipleNotch_ASDs.xml

2013-07-21_H1SUSQUADTST_DACNoise_COILOUTF_AvgASDw0p9-1-1p1HzTipleNotch_ASDs.xml

2013-07-21_H1SUSQUADTST_DACNoise_COILOUTF_AvgASDw4p5-5-5p5HzTipleNotch_ASDs.xml

2013-07-21_H1SUSQUADTST_DACNoise_COILOUTF_AvgASDw10-11-12HzTipleNotch_ASDs.xml

2013-07-21_H1SUSQUADTST_DACNoise_COILOUTF_AvgASDw30-32-34HzTipleNotch_ASDs.xml

The raw SR785 data files can be found here:

${SusSVN}/sus/trunk/QUAD/H1/QUADTST/Common/Data/18Bit_DACNoise_2013-07-21/SCRN*.TXT

with a key to what each number means in

${SusSVN}/sus/trunk/QUAD/H1/QUADTST/Common/Data/18Bit_DACNoise_2013-07-21/2013-07-21_MeasNotes.txt

The data is analyzed, and plots are produced with the following script:

${SusSVN}/sus/trunk/QUAD/H1/QUADTST/Common/Scripts/plot18bitdacnoise_20130721.m