Dan, Travis

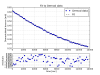

Tonight during our long lock we measured the decay time constant of the ITMX bounce mode. At 10:10 UTC we set the intent bit to "I solemnly swear I am up to no good" and flipped the sign on the ITMX_M0_DARM_DAMP_V filter bank and let the bounce mode ring up until it was about 3e-14 m/rt[Hz] in the DARM spectrum. Then, we zeroed the damping gain and let the mode slowly decay over the next few hours.

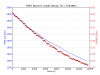

We measured the mode's Q by fitting the decay curve in two different datasets. The first dataset is the 16Hz-sampled output of Sheila's new RMS monitors; the ITMX bandpass filter is a 4th-order butterworth with corner frequencies of 9.83 and 9.87Hz (the mode frequency is 9.848Hz, +/- 0.001 Hz). This data was lowpassed at 1Hz and fit with an exponential curve.

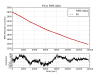

For the second dataset I followed Koji's demodulation recipe from the OMC 'beacon' measurement. I collected 20 seconds of DELTAL_EXTERNAL_DQ data, every 200 seconds; bandpassed at 9 and 12Hz, demodulated at 9.484Hz, and lowpassed at 2Hz; and collected the median value of the sum of the squares of the demod products. Some data were neglected on the edges of the 20-sec segment to avoid filter transients. These every-200-sec datapoints were fit with an exponential curve.

Results attached; the two methods give different results for Q:

RMS channel: 594,000

Demodulated DARM_ERR: 402,000

I fiddled with the data collection parameters and filtering parameters for both fits, but the results were robust. When varying parameters for each method the results for Q were repeatable within +/- 2,000, this gives some sense of the lower limit on uncertainty of the measurement. (The discrepancy between the two methods gives a sense of the upper limit...) Given a choice between the two I think I trust the RMS channel more, the demod path has more moving parts and there could be a subtlety in the filtering that I am overlooking. The code is attached.