Koji, Evan, Sheila

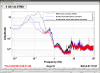

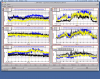

Tonight we saw the shelf from 50 up to 100 Hz, however we are back to a range of around 35 Mpc. We saw this last week and hoped that it was related to the HAM6 cleanroom. We have done several things:

- It seems that the peak at around 250 Hz is related to the OMCR path. The peak was reduced after the vent and replacement of the BS with a 90/10, and closeing the OMC refl beam diverter reduces it below the DARM noise floor.)

- closing POP and AS air beam diverters didn't seem to have any impact on the spectrum, the DHARD roll offs we added ddin't do much either.

- We measured fringe wrapping by exciting the OMC and OM1. Analysis coming tomorow, but at first it looks like the OMC backscatter should not be limiting the sensitivity.

- We were locked at 15 Watts for a few hours, after this time we saw broadband noise in DARM and tried to use the 785 to check for PI. We had used the 785 earlier in the lock, but the second time we weren't able to connect to it. By reducing the power we stayed locked. (An incorrect calibration around this time lead to a sensmon range of around 40 Mpc)

- ALS scanning is faster this week, since we added a fast scan durring the vent that checks the two most commonly found frequencies.

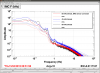

The first plot was measured with the injection of 20000cnt@0.2Hz to H1:SUS-OMC_M1_TEST_L_EXC.

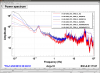

The second plot was measured with the injection of 10000cnt@0.2Hz to H1:SUS-OM1_M1_TEST_L_EXC.