Alexa, Sheila, Dan, Evan, Kiwamu

Tonight we have had good locking. The take home message tonight was that our noise changes with aligment, and so we think that we need to spend some time getting some ASC going (or at least a reproducible alingment) before we can make much progress on noise hunting. (see alog 16839)

We moved SR2, the difference between the noise spectrum before and after can probably be explained by the alignment depent noise rather than by reducing the rubbing (see alogs 16831 and 16811). The new positions are shown in the attahed screen shot. The SR3 OPLEV is not alinged any more. If someone wants to use the OpLev over the weekend, you will have to go back to the old alingment of SR2+3.

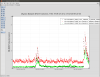

Turning on the OMC dither alingment improved the spectrum from 20-70 Hz in a way that is reproducble. The main improvement in the noise tonight came from alinging IM4, which resulted in the best spectrum we have had so far around 100 Hz. Note, the attached spectra are not calibrated!

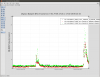

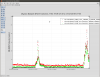

To add to the expanding ecology of H1 noise curves, here is a progression of our 2.8W locks for the past week and a half.

Also tonight Sheila has added the ETMY bounce mode damping to the Guardian with gain of -100. This has been working very well, the bounce mode is the lowest it's ever been.

Just out of curiosity, here is a rough estimate of the calibrated DARM spectrum for the 2.8 W lock. This was done assuming the spectrum is shot-noise limited above 1 kHz (except for the bump).