Evan, Sheila

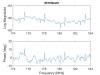

Tonight we have some evidence that the work on recylcing gain has helped us, Evan will attach the DARM spectrum.

Restoring the green camera offsets to the ones used during the mini run means that we can again lock with a recycling gain of ~37. These wrong references and the bad alignment that went with it has probably caused some of the frequent lock losses of the last two days, and headaches in turning on ASC in full lock. Hopefully we can leave all green references alone for at least a week and see that they really do bring us back to a good recycling gain consistently. My comments from yesterday about trying to figure out what drifts in green should be ignored.

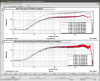

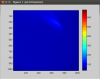

We did some injections of noise into SRCL with all of our boosts on (MICH L, SRCL, DHARD P+Y), and the AS_C to SRM+SR2 loop at a 4 Hz bandwidth. 38 W/W recycling gain. UTC May 6 11:48-11:53 UTC, no SRCL FF but MICH FF was on. The goal was to see how stationary the coupling is now.

We also restored some of the ASC cut offs that were deleted during the recycling gain work, CHARD PIT +YAW, DHARD P+ Y (for DAHRD P we are only using one of the two cutoffs we had, a pair of complex poles at 12 Hz, we don't have enough phase to use the 8 Hz cut off anymore so we wil need to redesign it if we need it)

Other business

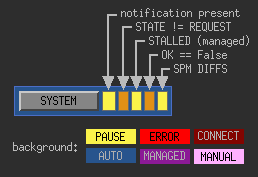

- We have had several locklosses during the analog CARM transition in the past few days. We edited the guardian so that the feedback is engaged as soon as the CM board input is enabled, this seems to have reduced the large kick that the BS and SRM were getting during this step.

- After maintenance today we saw that the H1:ASC-Y_TR_B_SUM_OFFSET offset had been changed, probably a bad safe.snap. We redid dark offsets for TRY B on each individual segment, NSUM, POP A LF, POPAIR A LFand POPAIR B LF. We also redid the normalization of each arm transmitted powers in a single arm lock, this meant changing H1:LSC-TR_X/Y_QPD_B_SUM_GAIN. We have accepted these changes in SDF.

- We also noted that the power on POPAIR A LF when MICH is locked on a dark fringe is 3.27uW, while the power on POPAIR B LF is 5.2 cnts, this doesn't seem to be calibrated.

We think that some usefull next steps on the list are

- Increasing SRM WFS gain, we made an attempt at this tonight but had trouble, and plan to come back to this task this evening

- picomotors for TMS Y QPDs when the recycling gain is good, which should allow us to close the ITM loops again. I dont' think that I aloged this in the past, but the strategy that worked for TMS Y QPD centering was to steer M14 to center on TRB, then steer M4 for TRA

- Add the remaining ASC cut offs back (INP1, PRC2, PRC1)

- using Gabriele's script to remeasure the ASC sensing matrix with good recycling gain

- 15-20 Watts

Spectrum attached. We are touching the 10 W GWINC curve from 200 Hz to 4 kHz. We have been able to do this a few times before by maxing out the gain of the CARM loop, but that was not necessary tonight.

Also I'm attaching a trend of POP90 and REFL_A_LF during the lock. There is some slow (perhaps thermal) drift. I looked at the PR3 and SR3 oplevs in pitch. PR3 seems to have a faster transient, while SR3 has a similarly slow drift. I tried touching SR3 to compensate for this (around 12:05:00Z), but it seemed to make no difference.

Also attaching a DARM OLTF.

The SRCL coupling is much more stationary now. During the noise injection, the coherence between DARM and SRCL was good. The first plot shows the measured TF between SRCL_OUT and the calibrated CAL-DELTAL signal.

I analyzed the data using the same technique explained in previous entries (17912, 17928, 18026). The second attachment shows that the coherence is stationary over time and the third attachment is an animation of the TF between SRCL_OUT and DARM over time. It's remarkably more stationary than before.

Finally, the last two attachments (4th and 5th) shows the time evolution of the transfer function at 30 Hz and 100 Hz. The residual variation of the TF is about 5%, which may very well be within the error of my estimaton.